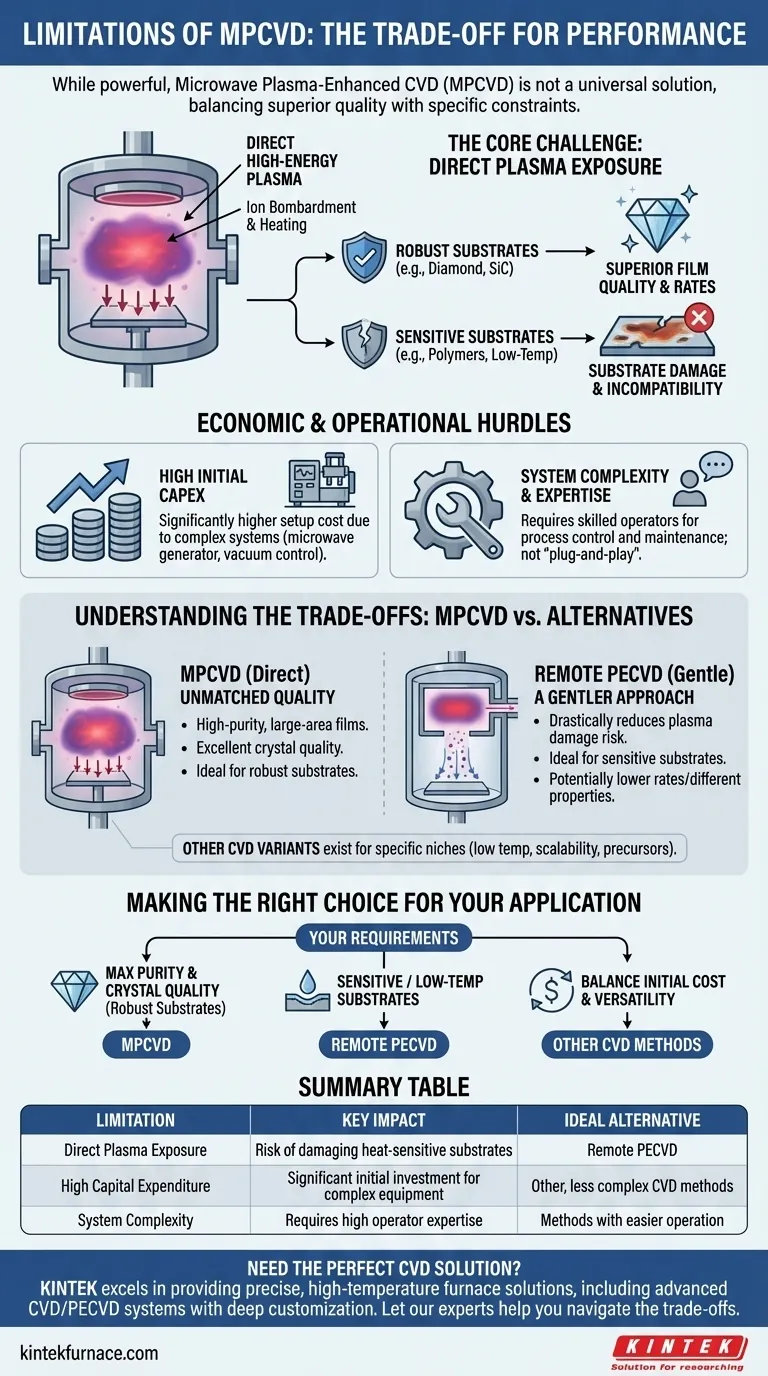

While powerful, Microwave Plasma-Enhanced Chemical Vapor Deposition (MPCVD) is not a universal solution. Its primary limitations are the high initial investment required for its complex equipment and its potential to damage sensitive substrates due to the direct, high-energy plasma environment. These factors constrain its use in applications involving delicate materials or those with strict budget limitations.

The core trade-off with MPCVD is performance versus gentleness. It leverages an intense, direct plasma to achieve superior film quality and deposition rates, but this very intensity makes it unsuitable for heat-sensitive materials and requires a significant upfront capital expenditure.

The Core Challenge: Direct Plasma Exposure

The defining characteristic of MPCVD is its high-density plasma generated directly in the reaction chamber. While this is the source of its power, it is also the origin of its main limitation.

Substrate Damage and Incompatibility

The high-energy microwave plasma creates a dense field of reactive species and charged particles. When a substrate is placed directly within this field, it can be subjected to ion bombardment and significant heating.

This environment is too harsh for many materials, particularly organic compounds, polymers, or other low-temperature substrates. The plasma can physically damage or chemically alter their surfaces, rendering the deposition process ineffective.

The Source of MPCVD's Power

This direct plasma exposure is precisely what enables MPCVD's key advantages. The high ionization degree, often exceeding 10%, creates a supersaturated environment of reactive atoms.

This leads to superior deposition rates and higher-quality films, particularly for hard materials like diamond, because the high density of precursors promotes excellent crystal growth and purity.

Economic and Operational Hurdles

Beyond the physics of the process, practical considerations also limit the application of MPCVD.

High Initial Capital Expenditure

MPCVD systems are inherently complex. They require a microwave generator, a waveguide, a resonant cavity, and sophisticated vacuum and gas flow control systems. This results in a significantly higher initial setup cost compared to many other CVD methods.

System Complexity and Expertise

The complexity of the equipment demands a higher level of operator expertise for process control, maintenance, and troubleshooting. This is not a "plug-and-play" technology and requires a dedicated and skilled team to run effectively.

Understanding the Trade-offs: MPCVD vs. Alternatives

Choosing a deposition method is about matching the technology's strengths and weaknesses to your specific goal. No method is best for everything.

The Case for MPCVD: Unmatched Quality

MPCVD excels when the goal is to produce high-purity, large-area films with exceptional crystal quality on robust substrates. For applications like synthetic diamond growth or advanced semiconductors, its ability to create a stable, contamination-free, high-density plasma is unparalleled.

The Case for Remote PECVD: A Gentler Approach

In contrast, Remote Plasma-Enhanced CVD (RPECVD) generates the plasma in a separate chamber. The reactive species are then transported to the substrate, which remains in a plasma-free region.

This method drastically reduces the risk of plasma-induced damage, making it ideal for sensitive substrates. However, this separation often results in a lower density of reactive species at the substrate, which can lead to lower deposition rates and potentially different film properties compared to MPCVD.

The Broader CVD Landscape

Other CVD variants exist to fill different niches. Some are optimized for lower temperatures, others for extreme scalability, or for compatibility with specific chemical precursors. MPCVD's limitations in one area are often solved by an alternative CVD method designed for that exact purpose.

Making the Right Choice for Your Application

Your material and performance requirements will dictate the correct technology choice.

- If your primary focus is maximum film purity and crystal quality for robust substrates (e.g., diamond, silicon carbide): MPCVD is likely the superior choice, as its performance justifies the initial investment.

- If your primary focus is depositing films on sensitive, low-temperature, or organic substrates: A method like Remote PECVD is a much safer alternative to avoid plasma-induced damage.

- If your primary focus is balancing initial cost with versatility across a range of non-sensitive materials: You should evaluate other, less complex CVD methods that may offer a more suitable cost-performance profile.

Understanding these core trade-offs empowers you to select the deposition technology that aligns perfectly with your material, performance, and budget requirements.

Summary Table:

| Limitation | Key Impact | Ideal Alternative for Sensitive Cases |

|---|---|---|

| Direct Plasma Exposure | Risk of damaging heat-sensitive substrates | Remote PECVD |

| High Capital Expenditure | Significant initial investment for complex equipment | Other, less complex CVD methods |

| System Complexity | Requires high operator expertise for maintenance & process control | Methods with easier operation |

Struggling to Choose the Right CVD Method for Your Unique Requirements?

Selecting the ideal Chemical Vapor Deposition system is a critical decision that balances performance, substrate compatibility, and budget. The limitations of MPCVD highlight that no single solution fits all applications.

KINTEK excels at providing the precise high-temperature furnace solution you need. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line—including advanced CVD/PECVD Systems—complemented by strong deep customization capabilities.

Whether your priority is unparalleled film purity on robust substrates or gentle deposition on sensitive materials, we can tailor a system to your exact experimental requirements.

Let our experts help you navigate the trade-offs and identify the optimal technology for your success.

Contact KINTEK today for a personalized consultation and discover how our advanced solutions can enhance your lab's capabilities.

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth

- Why is the temperature control system important in MPCVD equipment? Ensure Precise Diamond Growth and Process Stability

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- What is the relationship between diamond growth rate and quality in the MPCVD method? Balancing Speed and Purity for Your Application