In laboratory research, a vacuum tube furnace is a specialized instrument for heating materials to high temperatures within a precisely controlled atmosphere. Its applications span a wide range of scientific disciplines, including materials science for synthesizing novel compounds like nanomaterials and ceramics, semiconductor research for processes like annealing and diffusion, and chemical engineering for studying catalysts and creating thin films through chemical vapor deposition (CVD).

The core value of a vacuum tube furnace is not just its ability to achieve high heat, but its power to remove reactive gases like oxygen or introduce specific process gases. This environmental control is what enables the creation and processing of materials that would be impossible to develop in open air.

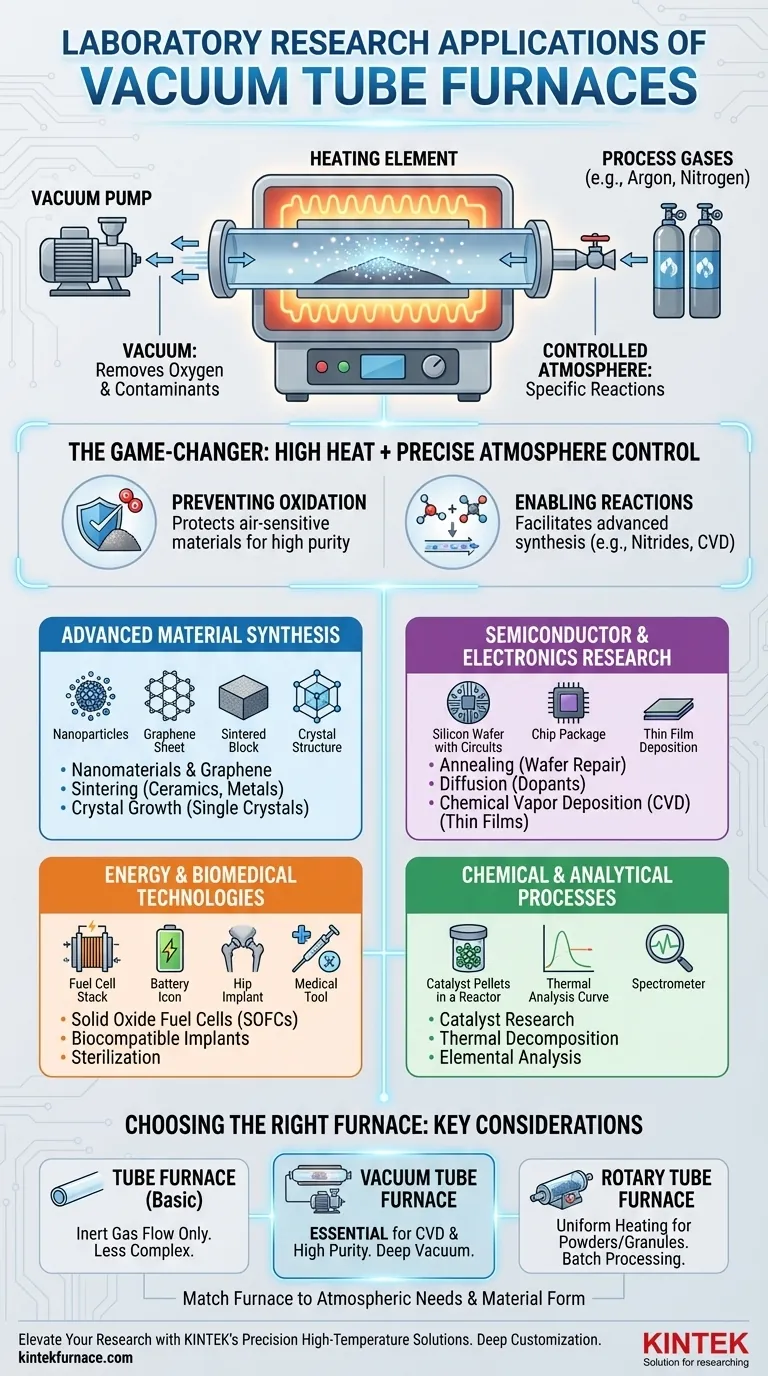

The Principle: Why Controlled Atmosphere is a Game-Changer

To understand the furnace's applications, you must first understand its fundamental advantage: atmospheric control. Simply heating a material in air can cause unwanted chemical reactions, primarily oxidation, which can ruin an experiment. A vacuum tube furnace solves this problem in two ways.

Preventing Oxidation and Contamination

The first step in many processes is to use a vacuum pump to evacuate the air from the sealed tube. This removes oxygen and other reactive gases. Creating this vacuum environment is critical for protecting air-sensitive materials and ensuring the final product has high purity.

Enabling Specific Chemical Reactions

Once a vacuum is established, the furnace allows for the introduction of specific, high-purity gases. This inert or reactive atmosphere is essential for advanced processes. For example, an inert gas like argon prevents reactions, while a reactive gas like nitrogen might be part of a nitride synthesis process.

Key Research Applications Breakdown

The ability to manipulate both temperature and atmosphere makes the vacuum tube furnace indispensable across several research domains.

Advanced Material Synthesis

This is the most common application. Researchers use these furnaces to create materials with novel properties that could not form in the presence of oxygen.

- Synthesis: Creating new materials like nanomaterials, graphene, superconducting materials, and polymer composites.

- Sintering: Fusing powders into a solid mass at high temperatures, used for ceramics, ceramic-metal composites, and refractory metals.

- Crystal Growth: Carefully controlling temperature gradients to grow single, high-purity crystals for research.

Semiconductor and Electronics Research

The manufacturing of electronic components relies on atomic-level precision, which requires pristine, controlled environments.

- Annealing: Heating semiconductor wafers to repair crystal lattice damage from prior processing steps and activate dopants.

- Diffusion: Introducing controlled impurities (dopants) into a semiconductor wafer at high temperatures to alter its electrical properties.

- Chemical Vapor Deposition (CVD): Flowing precursor gases through the heated tube to deposit an ultra-thin film onto a substrate, a cornerstone of chip manufacturing.

Energy and Biomedical Technologies

Developing next-generation energy and medical devices often involves materials that must be processed under exacting conditions.

- Solid Oxide Fuel Cells (SOFCs): Researching and fabricating the ceramic components used in advanced energy conversion systems.

- Biocompatible Implants: Sintering medical-grade metals or ceramics to create durable and safe implants.

- Sterilization: Heat-treating medical instruments in a clean, controlled environment.

Chemical and Analytical Processes

The furnace also serves as a micro-reactor for studying chemical transformations and analyzing material composition.

- Catalyst Research: Evaluating the activity, stability, and performance of catalysts under specific temperatures and gas flows.

- Thermal Decomposition: Studying how materials break down with heat to prepare new oxide, nitride, or carbide powders.

- Elemental Analysis: Heating a sample to release specific elements for measurement, often as part of a larger analytical system.

Understanding the Trade-offs: Choosing the Right Furnace

A vacuum tube furnace is a powerful tool, but it's not always the necessary choice. Understanding its alternatives is key to equipping a lab properly.

Tube Furnace vs. Muffle Furnace

A muffle furnace is a simpler heating box that operates in ambient air. It's excellent for general-purpose heating, determining the ash content of a sample, or heat treatments where oxidation is not a concern. A tube furnace is required only when you need to control the gaseous environment.

The Role of Vacuum

The "vacuum" capability is the defining feature. If your process simply requires an inert gas flow without the need for a deep vacuum to first remove all atmospheric contaminants, a simpler tube furnace without a vacuum system might suffice. However, for high-purity synthesis or CVD, a vacuum is non-negotiable.

When to Use a Rotary Tube Furnace

For processing batches of powders or granules, a rotary tube furnace is superior. As the tube rotates, it tumbles the material, ensuring every particle is heated uniformly. This is ideal for applications like powder roasting or large-scale material synthesis where consistency is critical.

Making the Right Choice for Your Goal

Selecting the correct heating instrument is fundamental to experimental success. Your decision should be driven entirely by the atmospheric requirements of your process.

- If your primary focus is synthesizing air-sensitive materials or depositing thin films (CVD): A vacuum tube furnace is essential for its atmospheric control.

- If your primary focus is general heat treatment, moisture analysis, or ashing in air: A less complex and more cost-effective muffle furnace is the correct tool.

- If your primary focus is achieving maximum heating uniformity for a batch of powder: A rotary tube furnace is the ideal choice for consistent results.

Ultimately, matching the furnace's capabilities to your precise experimental needs is the first step toward reproducible and groundbreaking results.

Summary Table:

| Application Area | Key Uses |

|---|---|

| Advanced Material Synthesis | Nanomaterials, ceramics, sintering, crystal growth |

| Semiconductor Research | Annealing, diffusion, CVD for thin films |

| Energy and Biomedical Tech | SOFCs, biocompatible implants, sterilization |

| Chemical Processes | Catalyst research, thermal decomposition, elemental analysis |

Ready to elevate your laboratory research with precision high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnace systems tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in materials science, semiconductor development, or energy research, we can help you achieve reproducible, groundbreaking results. Contact us today to discuss how our solutions can benefit your lab!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing