In short, the key technological advancements in modern muffle furnaces revolve around precision, efficiency, and versatility. These are driven by intelligent digital controllers, superior insulation and heating elements for energy savings, and sophisticated systems for controlling the furnace atmosphere, making them far more than simple heating boxes.

The core takeaway is that modern muffle furnaces have been transformed from basic, high-temperature ovens into precise, data-driven instruments. These advancements allow for greater experimental reproducibility, significant energy savings, and the ability to process materials in highly specific, controlled environments.

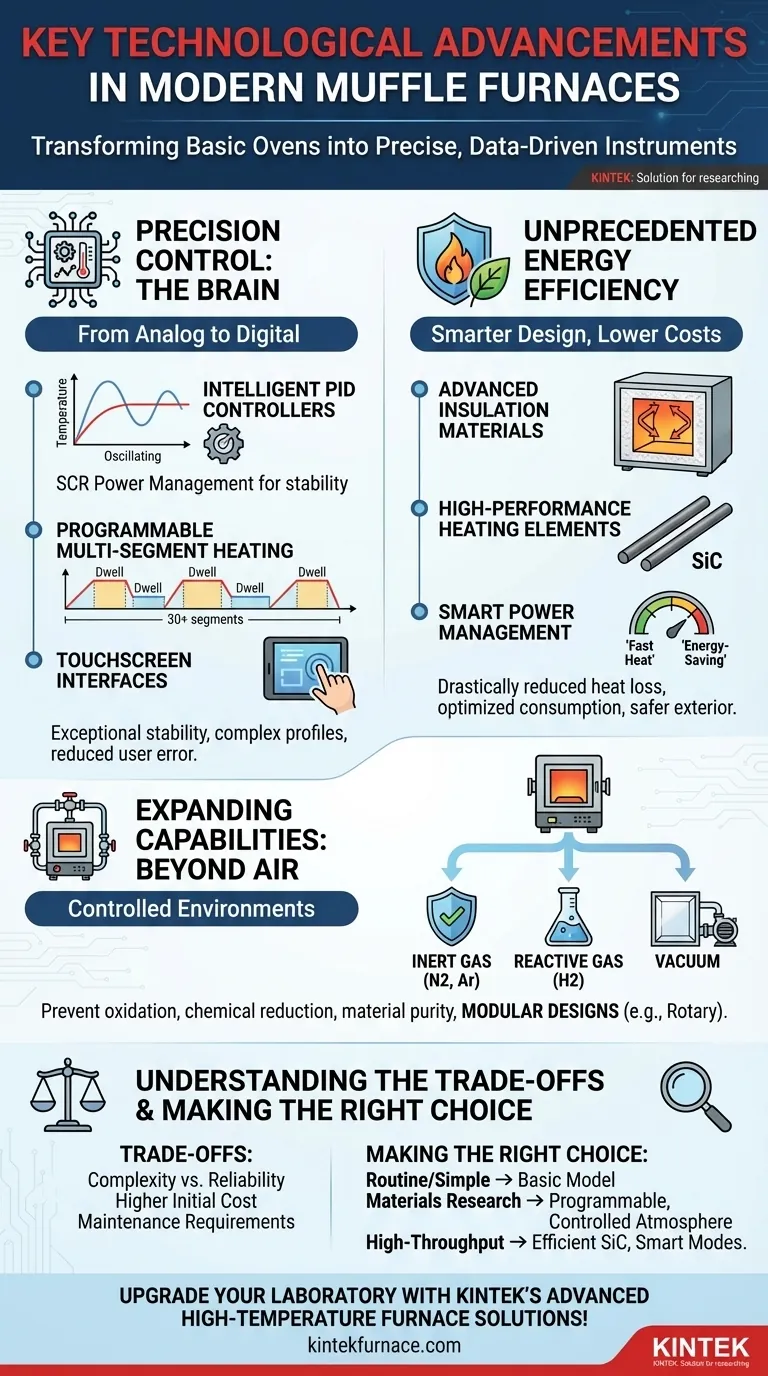

Precision Control: The Brains of the Modern Furnace

The single greatest leap in furnace technology is the move from analog to digital control. This provides a level of precision and repeatability that was previously unattainable.

Intelligent PID Controllers

Modern furnaces use PID (Proportional-Integral-Derivative) automatic control systems. This isn't just a simple thermostat; it's an algorithm that constantly anticipates and corrects temperature fluctuations, ensuring exceptional stability.

These systems often use Silicon Controlled Rectifiers (SCRs) to manage power. Unlike a simple on/off switch, SCRs deliver smooth, variable power to the heating elements, preventing temperature overshoots and undershoots.

Programmable, Multi-Segment Heating

Users can now program complex heating profiles. A typical modern controller allows for 30 or more programmable segments, enabling precise control over temperature ramps, dwell times, and cooling rates.

This is critical for applications like advanced materials research, complex heat-treating, and thermogravimetric analysis (TGA), where the thermal journey of the sample is as important as the final temperature.

User-Friendly Interfaces

Complex programming is made simple through intuitive touchscreen interfaces. This replaces confusing dials and buttons, reducing user error and making advanced capabilities accessible to all lab personnel.

Unprecedented Energy Efficiency

While achieving temperatures over 1000°C, modern furnaces are designed to be remarkably energy-efficient. This is accomplished through a combination of superior materials and intelligent software.

Advanced Insulation Materials

The furnace chamber is lined with advanced ceramic fiber insulation. This material has extremely low thermal conductivity, which drastically reduces heat loss to the environment.

The practical benefit is twofold: less energy is wasted maintaining temperature, and the exterior of the furnace remains cooler and safer.

High-Performance Heating Elements

Many high-performance furnaces now use silicon carbide (SiC) heating elements. These are more efficient at converting electricity into heat and offer greater stability and a longer service life compared to traditional metallic elements.

Smart Power Management

Intelligent controllers include energy-saving modes. The furnace can use maximum power for a "fast heat" mode to reach the setpoint quickly, then automatically reduce power output to the minimum required to maintain a stable temperature, optimizing energy consumption.

Expanding Capabilities: Beyond Simple Air Heating

Modern furnaces are no longer limited to heating objects in ambient air. They have become versatile tools for processing materials under highly specific conditions.

Controlled Atmosphere Systems

A major advancement is the ability to control the furnace's internal atmosphere. This allows for heat treatment in a variety of environments, including:

- Inert Gas: Using nitrogen or argon to prevent oxidation of sensitive materials.

- Reactive Gas: Using gases like hydrogen for specific chemical reduction processes.

- Vacuum: Removing air entirely to prevent any gas-phase reactions.

This capability is essential for metallurgy, electronics, and advanced materials science, where material purity is paramount.

Modular and Specialized Designs

Furnaces are now available in modular and customizable configurations. This includes interchangeable furnace tubes of different materials and diameters.

Specialized designs, such as rotary furnaces, are also available for applications requiring continuous processing or uniform treatment of powders and granular materials.

Understanding the Trade-offs

While advanced features offer significant benefits, they also introduce new considerations that every user must weigh.

Complexity vs. Reliability

A furnace with atmosphere control, vacuum pumps, and a multi-segment programmable controller has more potential points of failure than a simple box furnace. For basic, repetitive tasks, a less complex model may offer greater long-term reliability.

Cost of Advanced Features

The initial purchase price increases significantly with each advanced feature. High-efficiency insulation, SiC elements, and gas/vacuum systems represent a substantial investment compared to a basic furnace.

Maintenance Requirements

Controlled atmosphere systems require regular maintenance of gas lines, seals, and vacuum pumps. The cost of consumable gases and potential replacement of specialized components should be factored into the total cost of ownership.

Making the Right Choice for Your Application

Selecting the right furnace means matching its technology to your specific goal.

- If your primary focus is routine ashing or simple heat-treating: A basic model with good ceramic fiber insulation and a simple digital PID controller offers the best balance of performance and cost.

- If your primary focus is materials research or process development: Prioritize a furnace with a multi-segment programmable controller and controlled atmosphere or vacuum capabilities.

- If your primary focus is high-throughput or minimizing operational costs: Seek out models with the most efficient SiC heating elements, advanced insulation, and smart energy-saving software modes.

Ultimately, understanding these technological advancements empowers you to select a tool that is not just a furnace, but a precise instrument engineered for your specific task.

Summary Table:

| Advancement | Key Features | Benefits |

|---|---|---|

| Precision Control | PID controllers, SCR power, programmable segments, touchscreen interfaces | Accurate temperature stability, repeatable results, reduced user error |

| Energy Efficiency | Ceramic fiber insulation, SiC heating elements, smart power management | Lower energy consumption, cost savings, safer operation |

| Versatility | Controlled atmosphere systems (inert, reactive, vacuum), modular designs | Broad application range, material purity, customization for specific needs |

| Trade-offs | Increased complexity, higher initial cost, maintenance requirements | Considerations for reliability, budget, and long-term ownership |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with precision tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental requirements, delivering enhanced efficiency, reproducibility, and cost savings. Contact us today to discuss how our solutions can transform your material processing and research outcomes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency