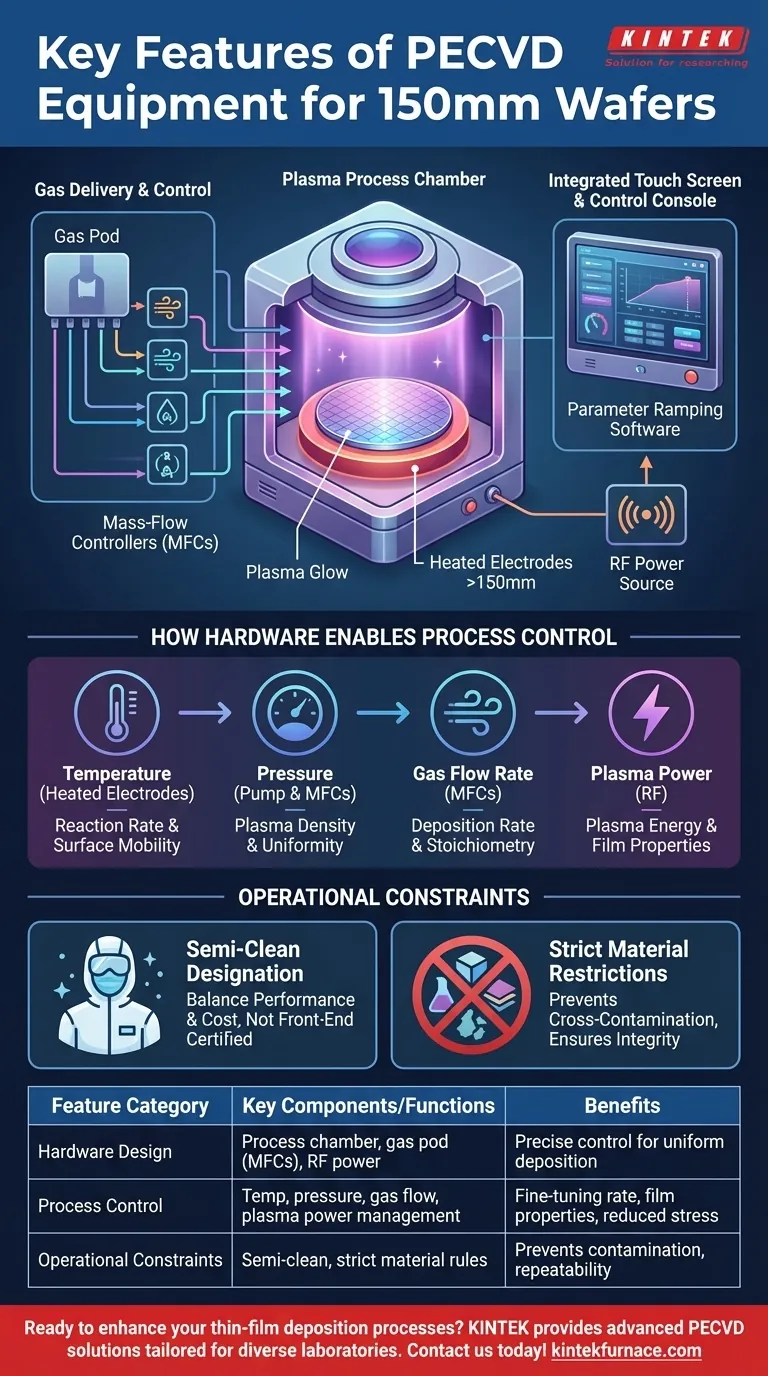

At its core, Plasma-Enhanced Chemical Vapor Deposition (PECVD) equipment for 150mm wafers combines precise hardware control with specific operational restrictions to ensure high-quality film deposition. Key features include a process chamber with heated electrodes larger than 150mm, a multi-line gas pod with mass-flow controllers for precursor accuracy, and radio-frequency (RF) power for plasma generation. Operationally, these systems are often designated as "semi-clean" and are the most restrictive regarding the types of substrate materials allowed.

The defining characteristic of a 150mm PECVD system is its balance between sophisticated process control and strict operational protocols. The hardware is designed for precise manipulation of temperature, pressure, gas flow, and plasma, but its effectiveness is entirely dependent on adhering to its restrictive material policies to prevent contamination.

Core Hardware and System Design

The physical components of the PECVD system are engineered to create a stable and highly controllable environment for thin-film growth.

The Process Chamber and Electrodes

The heart of the system is the process chamber, which houses the wafer during deposition. It features a large pumping port (e.g., 160 mm) to achieve the necessary vacuum levels.

Inside, a heated upper electrode and a lower electrode work in tandem. The lower electrode, which holds the wafer, must be larger than the substrate (e.g., 205 mm for a 150mm wafer) and is electrically heated to provide precise temperature control.

Gas Delivery and Control

A sophisticated gas delivery system is critical for controlling the chemical reaction. These systems typically feature a gas pod with multiple (e.g., 12) gas lines.

Each line is governed by a mass-flow controller (MFC), which ensures the exact flow rate of precursor and carrier gases enters the chamber, directly influencing the film's composition and deposition rate.

Plasma Generation and System Software

Plasma is generated using a radio frequency (RF) power source connected to the electrodes. This RF enhancement is what allows for deposition at much lower temperatures than conventional CVD by energizing the precursor gases.

Modern systems are managed through an integrated touch screen and control console. This includes parameter ramping software, allowing operators to program gradual changes in temperature, pressure, or gas flow during a process run.

How Hardware Enables Process Control

The equipment's features directly enable the fine-tuning of the four key process parameters that define the final film's properties.

Temperature

Controlled by the heated electrodes, temperature dictates the surface mobility of atoms and the rate of chemical reactions. Lower temperatures, a key benefit of PECVD, reduce thermal stress on the substrate.

Pressure

Managed by the vacuum pump and MFC gas input, chamber pressure influences the plasma's density and uniformity. It also affects the mean free path of molecules, which impacts how they arrive at the wafer surface.

Gas Flow Rate

Precisely managed by the MFCs, the flow rate determines the availability of reactant species. This is a primary lever for controlling the deposition rate and the stoichiometry (elemental ratio) of the resulting film.

Plasma Power

The RF power setting determines the energy and density of the plasma. Higher power can increase deposition rates but also increases ion bombardment, which can affect film stress and density.

Understanding the Operational Constraints

Beyond hardware, the operational rules of a PECVD system are a defining feature that ensures process integrity and repeatability.

The "Semi-Clean" Designation

A 150mm PECVD is often a semi-clean tool. This means it is cleaner than a typical R&D tool but not certified for the most sensitive front-end semiconductor fabrication lines. It strikes a balance between performance and cost.

Strict Material Restrictions

This is the most critical operational feature. To prevent cross-contamination that can ruin subsequent processes, these tools have a highly restrictive policy on allowed substrate materials and any materials already present on the samples.

For example, while a less-restrictive 100mm system might allow glass or GaAs substrates, a 150mm tool is often limited to specific types of wafers to maintain a pristine chamber environment. Failure to adhere to these rules is a primary cause of process failure.

Making the Right Choice for Your Goal

To use a 150mm PECVD system effectively, you must align its capabilities with your primary objective.

- If your primary focus is process repeatability and quality: Leverage the precise control offered by the MFC gas pod and parameter ramping software to develop a stable, reproducible recipe.

- If your primary focus is high throughput: Take advantage of the fast deposition rates and features like easy cleaning to minimize downtime between runs.

- If your primary focus is material compatibility: You must treat the tool's allowed materials list as an absolute rule to prevent chamber contamination and ensure consistent results for all users.

Understanding these features—from the hardware to the strict operational rules—is the foundation for achieving successful and repeatable thin-film deposition.

Summary Table:

| Feature Category | Key Components/Functions | Benefits |

|---|---|---|

| Hardware Design | Process chamber with heated electrodes (>150mm), gas pod with MFCs, RF power source | Enables precise temperature, pressure, and gas flow control for uniform film deposition |

| Process Control | Temperature control via electrodes, pressure management, gas flow via MFCs, plasma power via RF | Allows fine-tuning of deposition rate, film stoichiometry, and reduces thermal stress |

| Operational Constraints | Semi-clean designation, strict material restrictions | Prevents contamination, ensures process repeatability and high-quality results |

Ready to enhance your thin-film deposition processes? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need precise control for process repeatability, high throughput, or material compatibility, KINTEK has the expertise and equipment to help you achieve superior results. Contact us today to discuss how our PECVD systems can optimize your research and development!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication