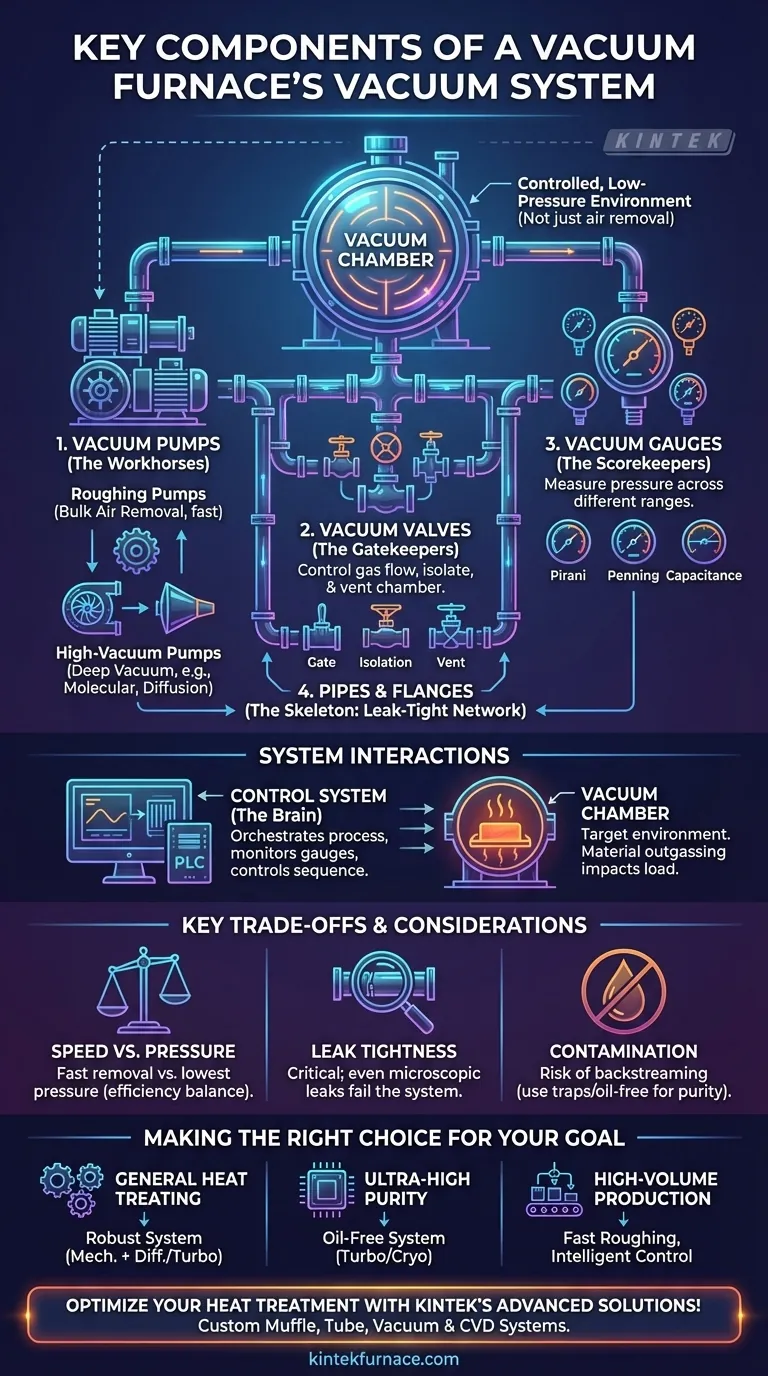

Fundamentally, a vacuum furnace's vacuum system is comprised of three core functional parts: vacuum pumps to remove air and other gases, vacuum valves to direct and control gas flow, and vacuum gauges to measure the pressure. These components are connected by a network of pipes and flanges, working together to create the controlled, low-pressure environment essential for high-quality heat treatment.

The purpose of a vacuum system is not simply to remove air, but to precisely engineer a sub-atmospheric environment. Each component plays a distinct and coordinated role—from initial bulk gas removal to achieving deep vacuum levels—ensuring a pure, predictable, and contamination-free space for processing materials.

The Anatomy of a Vacuum System

While a vacuum furnace has many parts like heating elements and cooling systems, the vacuum system itself is a specialized subsystem dedicated entirely to creating and maintaining the vacuum. It can be broken down into four essential categories.

The Workhorses: Vacuum Pumps

No single pump is efficient across the entire pressure range from atmosphere to high vacuum. Therefore, systems use a multi-stage approach.

-

Roughing Pumps (Mechanical Pumps): These are the first stage of evacuation. They are designed to remove the bulk of the air from the furnace chamber quickly, taking the pressure from atmospheric down to a "rough" vacuum level.

-

High-Vacuum Pumps: Once the roughing pump has done its job, a high-vacuum pump takes over to achieve the much lower pressures required for processing. Common types include molecular pumps (like turbomolecular pumps) or diffusion pumps, which can create the near-perfect vacuum needed to prevent oxidation and contamination.

The Gatekeepers: Vacuum Valves

Valves are the traffic controllers of the vacuum system. They open and close in a specific sequence to manage the evacuation process.

Their key functions include isolating the furnace chamber from the pumps, switching between the roughing and high-vacuum pumps, and allowing the chamber to be safely vented back to atmospheric pressure with a controlled gas like nitrogen or argon.

The Scorekeeper: Vacuum Gauges

You cannot control what you cannot measure. Vacuum gauges are the sensory organs of the system, providing the critical pressure readings that inform both the operator and the automated control system.

Because pressure spans many orders of magnitude, different types of gauges are often used to accurately measure pressure at different stages of the pump-down cycle.

The Skeleton: Pipes and Flanges

This network of stainless steel tubing and sealed connections is the circulatory system that connects the pumps, valves, and gauges to the main furnace chamber.

The integrity of this "plumbing" is paramount. The entire system's performance depends on these connections being perfectly sealed and leak-tight.

How the System Interacts with the Furnace

The vacuum system does not operate in isolation. It is intrinsically linked to the furnace chamber and the master control system.

The Vacuum Chamber

The chamber is the sealed vessel where the actual heating and processing take place. It is the environment that the vacuum system acts upon. The volume of the chamber and the materials being processed (which can release trapped gases, a phenomenon called outgassing) directly impact how hard the vacuum system must work.

The Control System

The control system is the brain of the operation. It orchestrates the entire process by following a pre-programmed recipe. It tells the valves when to open and close, starts and stops the pumps in the correct sequence, and constantly monitors the vacuum gauges to ensure the target pressure is reached and maintained.

Understanding Key Trade-offs and Considerations

A vacuum system's design is a balance of competing priorities. Understanding these helps you appreciate why certain choices are made.

Pumping Speed vs. Ultimate Pressure

There is a direct trade-off between how fast a system can remove gas and the lowest possible pressure it can achieve. Roughing pumps are fast but have a poor ultimate vacuum. High-vacuum pumps can reach exceptionally low pressures but are inefficient at removing large volumes of gas. A well-designed system uses both to optimize cycle time.

The Critical Role of Leak Tightness

A vacuum system is only as good as its weakest seal. Even a microscopic leak in a flange, valve, or weld can introduce a steady flow of air into the chamber, preventing the system from ever reaching its target pressure. Regular leak checking is a critical maintenance task.

Contamination and Backstreaming

In systems using oil-sealed mechanical pumps or older oil diffusion pumps, there is a risk of oil vapor migrating from the pump back into the clean vacuum chamber. This "backstreaming" can contaminate the parts being processed. Modern systems use specific traps or oil-free pumps (like turbomolecular or cryopumps) to mitigate this risk for sensitive applications.

Making the Right Choice for Your Goal

The specific configuration of a vacuum system is dictated by the process it needs to support.

- If your primary focus is general heat treating or brazing: A robust system with a mechanical roughing pump and a reliable diffusion or turbomolecular pump is the industry standard for performance and reliability.

- If your primary focus is ultra-high purity processes (e.g., medical implants, electronics): Prioritize an oil-free system with turbomolecular or cryopumps to completely eliminate the risk of hydrocarbon contamination.

- If your primary focus is high-volume production: The size and speed of your roughing pump, combined with an intelligent control system, are paramount for minimizing pump-down time and maximizing throughput.

Understanding how these core components function as a cohesive system empowers you to operate, maintain, and specify a vacuum furnace with confidence.

Summary Table:

| Component | Function | Key Types |

|---|---|---|

| Vacuum Pumps | Remove gases to create vacuum | Roughing pumps, High-vacuum pumps (e.g., turbomolecular, diffusion) |

| Vacuum Valves | Control gas flow and isolate sections | Isolation valves, Vent valves |

| Vacuum Gauges | Measure pressure levels | Various types for different pressure ranges |

| Pipes and Flanges | Connect components and ensure leak-tight seals | Stainless steel tubing with sealed connections |

Optimize your laboratory's heat treatment with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing purity, efficiency, and throughput. Contact us today to discuss how we can support your specific goals!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion