In essence, a modular Plasma-Enhanced Chemical Vapor Deposition (PECVD) system provides significant operational advantages for solar cell manufacturing, primarily by maximizing production uptime and throughput. This architecture allows individual process chambers to be serviced or cleaned offline without halting the entire production line, leading to cost-effective mass production, efficient material use, and consistent high-quality film deposition.

The core value of a modular PECVD system is not just the quality of the films it produces, but its ability to solve the primary challenge of industrial-scale manufacturing: minimizing costly downtime. It transforms a traditionally stop-and-start process into a more continuous and economically efficient operation.

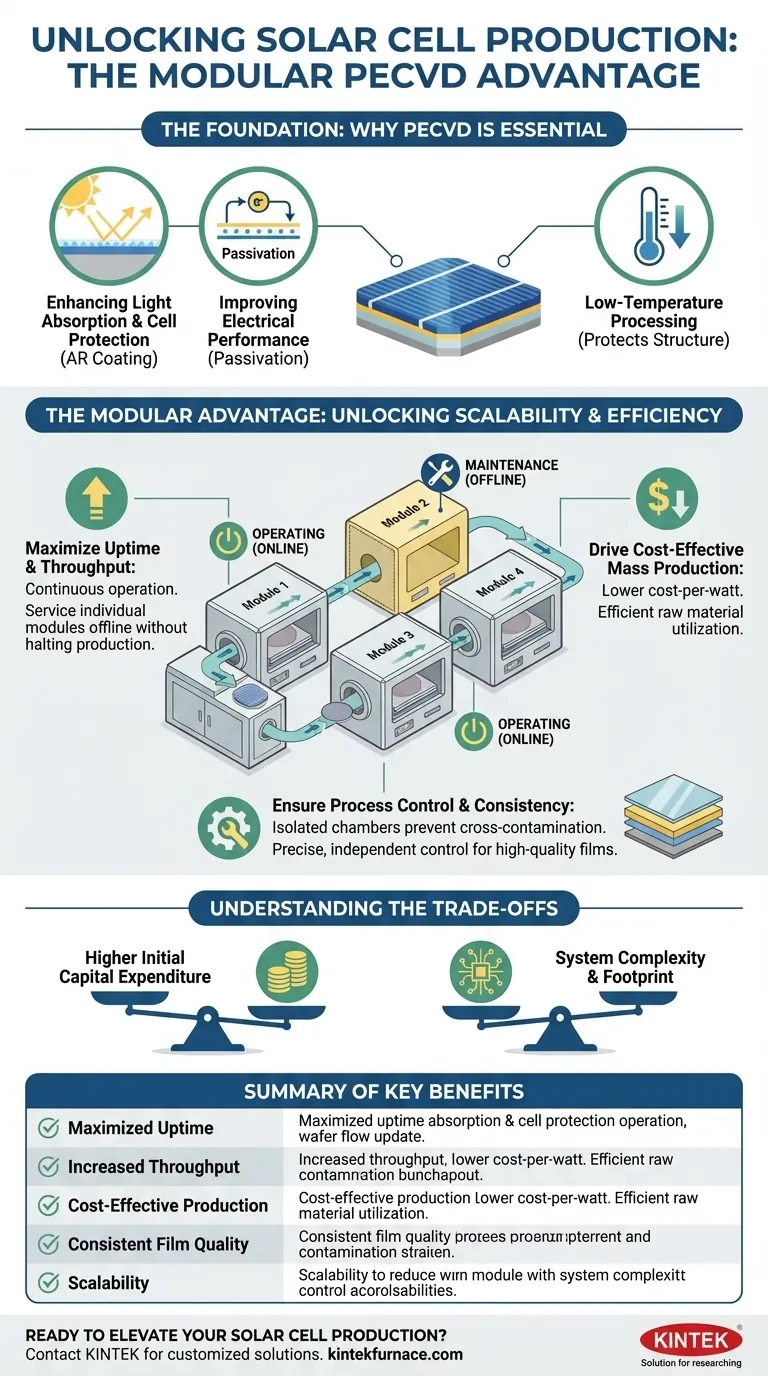

The Foundation: Why PECVD is Essential for Solar Cells

To understand the modular advantage, we must first recognize the fundamental role PECVD plays in creating efficient solar cells. It is the go-to technology for depositing critical thin films onto silicon wafers.

### Enhancing Light Absorption and Cell Protection

PECVD is used to apply an anti-reflective (AR) coating, typically made of silicon nitride (SiNx). This microscopic layer is crucial for trapping more sunlight, reducing reflection, and therefore increasing the amount of energy the cell can convert.

This same SiNx layer also serves as a protective barrier, shielding the delicate cell surface from moisture and contamination that could degrade its performance over time.

### Improving Electrical Performance (Passivation)

During the deposition process, the hydrogen-rich SiNx film performs a critical function called passivation. It effectively "heals" microscopic defects and neutralizes stray electrical charges (dangling bonds) within the silicon wafer.

This passivation improves the mobility of charge carriers (electrons), allowing them to flow more freely and increasing the overall efficiency of the solar cell.

### The Advantage of Low-Temperature Processing

Unlike traditional Chemical Vapor Deposition (CVD), PECVD operates at much lower temperatures. This is vital for protecting the delicate, pre-existing structures of the solar cell from thermal damage during the coating process.

The Modular Advantage: Unlocking Production Scalability

While standard PECVD provides the necessary film quality, the modular architecture is what enables true industrial-scale efficiency. It rethinks the machine's design to directly address the bottlenecks of mass production.

### Maximizing Uptime and Throughput

In a traditional, single-chamber system, the entire machine must be shut down for routine cleaning and maintenance. This is a significant source of lost production time.

A modular system consists of multiple, independent process chambers. When one module requires cleaning, it can be taken offline while the others continue to operate. This dramatically increases overall equipment uptime and factory throughput.

### Driving Cost-Effective Mass Production

Higher uptime and throughput translate directly to a lower manufacturing cost per solar cell and, ultimately, a lower cost-per-watt.

Furthermore, these systems are designed for highly efficient raw material utilization, minimizing the waste of precursor gases and contributing to better production economics.

### Ensuring Process Control and Consistency

In a modular setup, different deposition steps can be isolated in dedicated chambers. This prevents cross-contamination between layers, which is critical when creating complex, multi-layer cell designs.

This separation allows for precise and independent control over temperature, pressure, and plasma conditions for each specific film, resulting in exceptional uniformity and repeatable, high-quality layer performance.

Understanding the Trade-offs

No technology is without its considerations. A modular approach introduces a different set of engineering and financial calculations compared to monolithic systems.

### Initial Capital Expenditure

Modular systems are inherently more complex, often involving advanced wafer-handling robotics and sophisticated control systems. This typically results in a higher initial capital investment compared to a single, large-batch PECVD reactor.

The decision to invest hinges on whether the gains in throughput and reduced operational costs will provide a sufficient return on the higher upfront expense.

### System Complexity and Footprint

Managing multiple independent process modules, vacuum systems, and gas lines increases the overall complexity of the equipment. This may require more specialized maintenance training and a potentially larger cleanroom footprint.

Making the Right Choice for Your Production Goals

Selecting the right PECVD architecture is a strategic decision that must align with your specific manufacturing objectives.

- If your primary focus is maximum output and lowest cost-per-watt: The superior uptime and throughput of a modular PECVD system make it the definitive choice for high-volume, cost-sensitive production.

- If your primary focus is R&D or small-scale, specialized production: A less expensive, single-chamber batch system may offer a more practical entry point, but it will lack the scalability for mass manufacturing.

- If your primary focus is advanced cell architectures with complex layers: The process isolation and precise control offered by a modular system are invaluable for ensuring the quality and repeatability of each distinct film.

Ultimately, adopting a modular PECVD system is a commitment to a high-efficiency, continuous-flow production philosophy.

Summary Table:

| Benefit | Description |

|---|---|

| Maximized Uptime | Individual chamber maintenance without halting production, reducing downtime. |

| Increased Throughput | Continuous operation boosts output, lowering cost-per-watt in mass production. |

| Cost-Effective Production | Efficient material use and reduced operational expenses improve ROI. |

| Consistent Film Quality | Precise control and isolation prevent contamination for high-performance layers. |

| Scalability | Modular design supports growth from pilot to high-volume manufacturing. |

Ready to elevate your solar cell production with advanced PECVD solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge high-temperature furnace systems, including our specialized CVD/PECVD systems. Our strong deep customization capability ensures we can precisely meet your unique experimental and production needs, helping you achieve higher efficiency, reduced costs, and scalable growth. Don't let downtime hold you back—contact us today to discuss how our modular PECVD systems can transform your operations!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

People Also Ask

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- What are the advantages of using CVD? Achieve High-Purity, Conformal Thin Films for Your Applications

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods