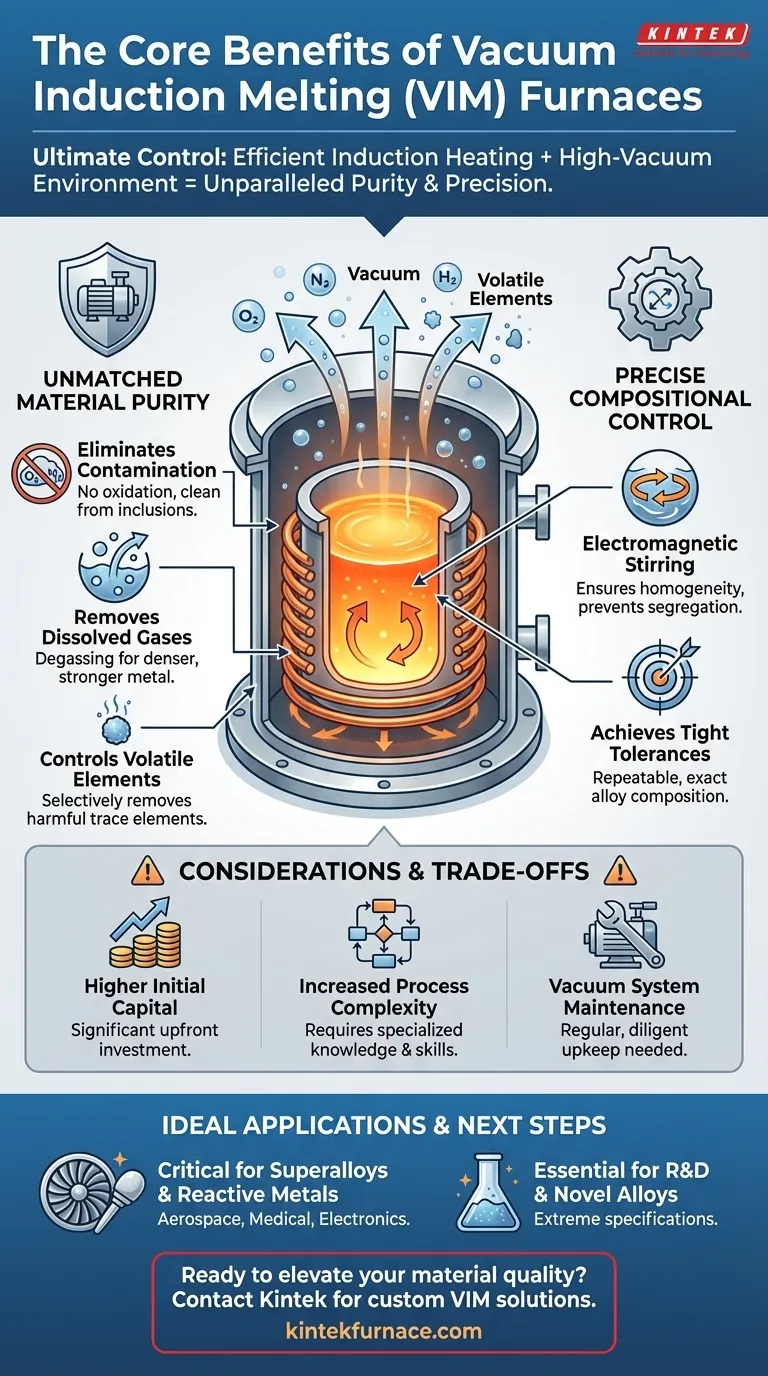

At its core, a Vacuum Induction Melting (VIM) furnace offers one primary advantage over all other melting technologies: ultimate control. It achieves this by combining efficient induction heating with a high-vacuum environment, resulting in unparalleled metal purity, precise alloy composition, and operational flexibility. This capability makes it indispensable for producing the high-performance materials required by demanding industries like aerospace, medical, and electronics.

Conventional melting exposes molten metal to atmospheric oxygen, nitrogen, and other contaminants, compromising its final properties. A VIM furnace fundamentally solves this by removing the atmosphere, enabling the creation of exceptionally clean and homogenous alloys that are impossible to produce otherwise.

How VIM Achieves Unmatched Material Purity

The defining feature of a VIM furnace is the vacuum. By removing the air from the melting chamber, it creates an ideal environment that directly enhances the quality of the final product.

Eliminating Atmospheric Contamination

In a traditional furnace, molten metal reacts with oxygen and nitrogen in the air. This process, known as oxidation, forms undesirable non-metallic inclusions (impurities) that can compromise the mechanical properties of the finished material.

The vacuum environment of a VIM furnace almost completely eliminates this source of contamination, ensuring the metal remains clean and free from oxide inclusions.

Removing Dissolved Gases

Gases like hydrogen can dissolve into molten metal and become trapped during solidification, creating porosity and causing embrittlement. This is a critical failure point in high-stress applications.

A VIM furnace uses the vacuum to actively pull these harmful dissolved gases out of the molten bath, a process called degassing. This results in a denser, stronger, and more reliable final product.

Controlling Volatile Elements

The controlled vacuum and temperature allow for the selective removal of harmful trace elements with high vapor pressures, such as lead or bismuth. This purification step further refines the alloy's composition to meet stringent specifications.

The Power of Precise Compositional Control

Beyond purity, a VIM furnace provides exceptional control over the final chemical makeup and structure of an alloy. This is achieved through the physics of induction and the highly controlled environment.

Electromagnetic Stirring for Homogeneity

The induction coil that heats the metal also generates a strong electromagnetic field. This field naturally and vigorously stirs the molten bath, ensuring all alloying elements are distributed perfectly evenly.

This electromagnetic stirring prevents segregation and guarantees the alloy is homogenous from top to bottom, resulting in consistent and predictable material properties.

Achieving Tight Compositional Tolerances

Because the system is a closed, controlled environment, operators can make precise alloying additions without losing material to oxidation. This allows for the production of alloys with an extremely close and repeatable compositional tolerance, which is critical for superalloys and other advanced materials.

Understanding the Trade-offs and Considerations

While powerful, a VIM furnace is a specialized piece of equipment. Its benefits come with practical considerations that must be weighed against its advantages.

Higher Initial Capital Cost

VIM systems are complex, involving not only a furnace but also robust vacuum pumps, sophisticated power supplies, and advanced control systems. This results in a significantly higher upfront investment compared to conventional air-melt furnaces.

Increased Process Complexity

Operating a VIM furnace requires more specialized knowledge than traditional melting. Managing vacuum levels, controlling temperature profiles, and executing the process under vacuum adds layers of operational complexity and requires skilled personnel.

Maintenance of Vacuum Systems

The vacuum system, including pumps, valves, and seals, is critical to the furnace's function. This system requires regular, diligent maintenance to ensure it operates reliably and can achieve the low pressures necessary for high-purity melting.

Is a VIM Furnace Right for Your Application?

The decision to invest in a VIM furnace should be driven entirely by the material quality requirements of your final product.

- If your primary focus is producing superalloys or reactive metals (like titanium and zirconium) for aerospace or medical use: VIM is not just a benefit; it is often a fundamental requirement to meet industry standards.

- If your primary focus is developing novel alloys with extremely tight chemical specifications: The purity, control, and repeatability offered by a VIM furnace are essential for research and successful development.

- If your primary focus is casting standard ferrous or non-ferrous alloys where some impurities are acceptable: The cost and complexity of a VIM furnace are likely unnecessary, and a more conventional melting technology may be more cost-effective.

Ultimately, choosing a VIM furnace is an investment in achieving the highest possible standard of material purity and compositional control.

Summary Table:

| Benefit | Key Feature | Impact |

|---|---|---|

| Unmatched Purity | High-vacuum environment | Eliminates contamination and dissolved gases for cleaner alloys |

| Precise Composition | Electromagnetic stirring and controlled additions | Ensures homogeneity and tight compositional tolerances |

| Operational Flexibility | Closed, controlled system | Ideal for superalloys, reactive metals, and R&D applications |

Ready to elevate your material quality with a custom Vacuum Induction Melting furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions tailored to your unique needs. Our expertise in high-temperature furnaces ensures superior purity and control for industries like aerospace and medical. Contact us today to discuss how we can support your high-performance alloy production!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance