In essence, quality control for a dental lab furnace is a shared responsibility. It begins with the manufacturer's rigorous production standards and is carried through by the furnace's own performance features, but it is ultimately maintained by the dental lab’s disciplined operational and maintenance protocols. True quality assurance covers the entire lifecycle of the equipment, from factory to final restoration.

The core issue is not just buying a "good" furnace, but ensuring it delivers predictable, high-quality clinical results every single time. This requires understanding that quality control extends beyond the factory floor and into your daily lab operations.

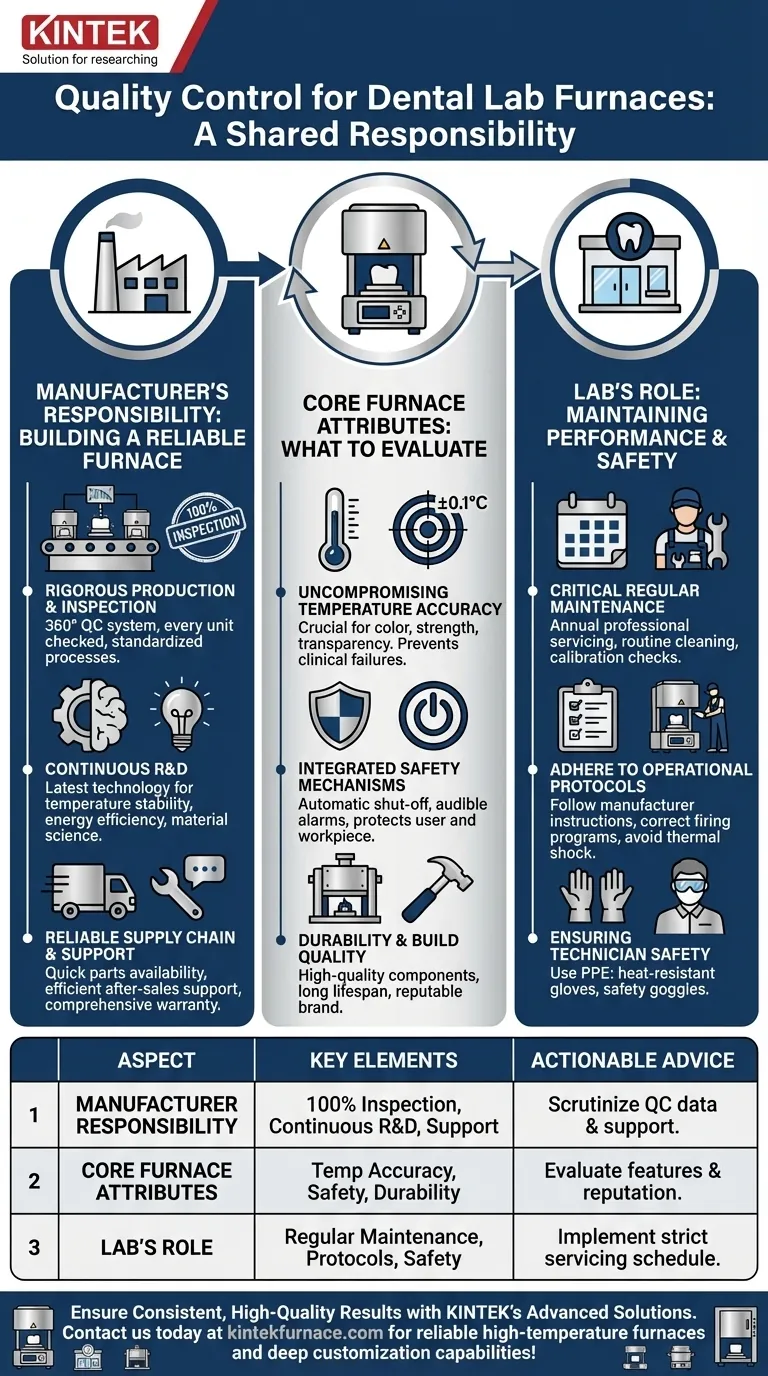

The Manufacturer's Responsibility: Building a Reliable Furnace

A high-quality furnace is the result of a manufacturer's deep commitment to process and precision. This isn't something you can easily see, so you must know what to ask for.

Rigorous Production and Inspection

Top-tier manufacturers implement a 360-degree quality control system. This means every single unit (100% product inspection) is checked, not just a random sample.

They rely on standardized production processes and large-scale data management to track performance and eliminate defects before a furnace ever leaves the factory.

Continuous Research and Development

Quality control starts with the design. A commitment to continuous research and development (R&D) ensures the furnace incorporates the latest technology for temperature stability, energy efficiency, and material science.

This proactive approach prevents known issues and improves the reliability of the firing cycles for new and existing dental materials.

A Reliable Supply Chain and Support

A manufacturer's quality is also reflected in its logistics and support. A reliable supply chain ensures that if you need a part or a new unit, it's available quickly.

Furthermore, efficient after-sales support and a comprehensive warranty are hallmarks of a company that stands behind its product's quality.

Core Furnace Attributes: What to Evaluate in the Equipment

Beyond the manufacturing process, the furnace itself must possess specific features that guarantee performance and safety. These are the tangible aspects you can verify.

Uncompromising Temperature Accuracy

This is the single most critical performance factor. Even minor variations in temperature during a firing cycle can ruin a restoration.

Inaccurate temperatures directly impact a material's final properties, including its color, strength, transparency, and bond strength. This can lead to clinical failures like fractures or discoloration.

Integrated Safety Mechanisms

A quality furnace protects both the user and the workpiece. Look for built-in safety mechanisms that operate automatically.

Key features include an automatic shut-off that kills power if the temperature exceeds safe limits and audible alarms that alert technicians to any malfunction.

Durability and Build Quality

The furnace must be built to withstand the demands of a busy lab. Durability is a direct reflection of the quality of the components used, from the heating elements to the insulation.

A manufacturer's brand reputation is often a reliable proxy for the expected lifespan and durability of their equipment.

The Lab's Role: Maintaining Performance and Safety

Once the furnace is in your lab, the responsibility for quality control shifts to you. Neglecting this final step will undermine even the best-made equipment.

The Critical Need for Regular Maintenance

Consistent performance depends on consistent care. A furnace should undergo professional servicing at least once a year to calibrate temperature and check for wear.

Routine cleaning of the chamber and components is also essential. Dust and debris can interfere with heating elements and temperature sensors, leading to inaccurate firings.

Adhering to Correct Operational Protocols

Always follow the manufacturer's instructions for operation. This includes using the correct firing programs for specific materials.

A common error is removing restorations before they have properly cooled. This thermal shock can introduce micro-fractures and compromise the integrity of the final product.

Ensuring Technician Safety

A quality-focused lab is a safe lab. All personnel operating the furnace must use appropriate personal protective equipment (PPE), including heat-resistant gloves and safety goggles.

How to Apply This to Your Lab

Use this framework to guide your purchasing decisions and internal protocols.

- If your primary focus is purchasing new equipment: Scrutinize the manufacturer's commitment to 100% inspection, R&D, and post-sale support, and demand data on temperature accuracy.

- If your primary focus is maximizing existing equipment: Implement and enforce a strict schedule for annual professional servicing, daily cleaning, and temperature calibration checks.

Ultimately, a disciplined approach to quality control, from the factory to your lab bench, is the foundation for delivering exceptional and reliable dental restorations.

Summary Table:

| Aspect | Key Elements |

|---|---|

| Manufacturer Responsibility | 100% product inspection, continuous R&D, reliable supply chain, efficient after-sales support |

| Core Furnace Attributes | Temperature accuracy, integrated safety mechanisms, durability and build quality |

| Lab's Role | Regular maintenance, adherence to operational protocols, technician safety with PPE |

Ensure your dental lab achieves consistent, high-quality results with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental needs, enhancing performance and safety. Contact us today to discuss how we can support your quality control goals!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations