The fundamental advantage of a vacuum hot press sintering furnace is its ability to simultaneously apply high temperature and mechanical pressure in a tightly controlled, oxygen-free environment. This combination produces materials with superior density, purity, and mechanical properties that are often unattainable with other methods.

While conventional furnaces rely solely on heat to bond material powders, vacuum hot pressing actively forces densification with pressure while the vacuum protects the material from contamination. This results in components with near-theoretical density and exceptional performance characteristics.

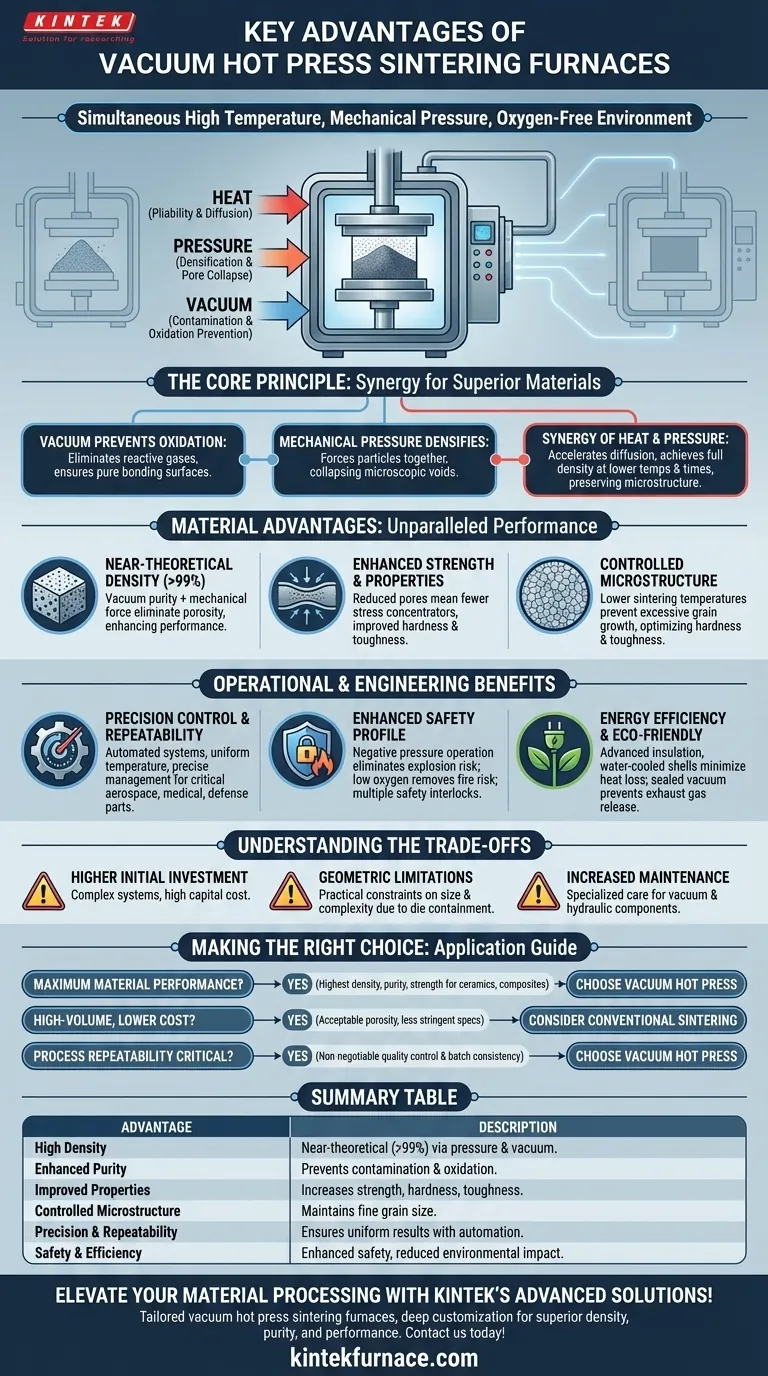

The Core Principle: Combining Pressure, Heat, and Vacuum

Understanding the synergy between these three elements is key to grasping the power of this technology. Each component solves a specific problem inherent in traditional material consolidation.

How Vacuum Prevents Contamination and Oxidation

By removing the atmosphere from the heating chamber, the furnace eliminates reactive gases like oxygen and nitrogen.

This is critical because at high temperatures, these gases readily form oxides and nitrides on the surface of material particles. These brittle layers act as barriers, preventing the particles from properly bonding and creating a weaker final product.

The vacuum ensures an ultra-pure environment, leading to cleaner material surfaces and superior inter-particle diffusion and bonding.

The Role of Mechanical Pressure in Densification

While heat encourages particles to bond, microscopic voids and pores can remain. A vacuum hot press applies external mechanical pressure throughout the heating cycle.

This pressure physically forces the particles together, collapsing pores and eliminating voids far more effectively than heat alone. The result is a final product with significantly higher density.

The Synergy of Heat and Pressure

Heat makes the material pliable, allowing the particles to deform and rearrange under the applied load. Pressure, in turn, accelerates the diffusion process that bonds the particles.

This synergy means you can often achieve full densification at lower temperatures and in shorter timeframes compared to pressureless sintering, which helps preserve the material's desired fine-grained microstructure.

Unpacking the Key Material Advantages

The unique process inside a vacuum hot press directly translates to measurable improvements in the final material.

Achieving Near-Theoretical Density

The combination of vacuum purity and mechanical force is exceptionally effective at eliminating porosity.

Materials processed in a vacuum hot press can achieve densities greater than 99% of their theoretical maximum. This lack of voids is the primary reason for their enhanced performance.

Enhancing Strength and Mechanical Properties

Porosity is the single greatest enemy of mechanical strength, as pores act as stress concentrators and points of crack initiation.

By creating nearly fully dense parts, vacuum hot pressing produces components with dramatically improved hardness, fracture toughness, and overall structural integrity.

Controlling Microstructure and Grain Size

The ability to sinter at lower temperatures and for shorter durations helps prevent excessive grain growth.

Maintaining a fine, uniform grain structure is crucial for achieving a superior combination of hardness and toughness in many advanced materials, particularly ceramics.

Operational and Engineering Benefits

Beyond the material itself, these furnaces are designed for precision, safety, and efficiency.

Precision Control and Repeatability

Modern vacuum hot presses are highly automated systems. Computer controls, optimized heating element placement, and advanced thermocouples ensure uniform temperature distribution and precise process management.

This high degree of control ensures that every part produced meets the exact same specifications, providing the metallurgical repeatability required for critical applications in aerospace, medical, and defense.

Enhanced Safety Profile

Unlike furnaces that operate under positive pressure, a vacuum furnace operates at negative pressure. This inherently eliminates the risk of a high-pressure explosion.

Furthermore, the low-oxygen environment virtually removes the risk of fire from material oxidation at high temperatures. These systems are equipped with multiple safety interlocks, including alarms for over-temperature, over-current, and cooling water failure.

Energy Efficiency and Environmental Impact

Advanced insulation materials, such as graphite felt, and double-layer water-cooled shells minimize heat loss, reducing overall energy consumption.

The sealed vacuum environment also prevents the release of exhaust gases, ensuring the process meets stringent environmental standards without requiring costly secondary treatment systems.

Understanding the Trade-offs

No technology is without its compromises. Objectivity requires acknowledging the limitations.

Higher Initial Investment

Vacuum hot press furnaces are complex machines. The vacuum pumping systems, high-force hydraulic presses, and sophisticated control instrumentation result in a significantly higher capital cost compared to simpler atmospheric furnaces.

Geometric and Size Limitations

The need to contain the workpiece within a die and apply uniform pressure places practical constraints on the size and complexity of the parts that can be produced.

Increased Maintenance Complexity

The vacuum systems, high-pressure seals, and hydraulic components require more specialized and frequent maintenance than a conventional heating furnace to ensure optimal performance and longevity.

Making the Right Choice for Your Application

Use these guidelines to determine if this technology aligns with your project's goals.

- If your primary focus is maximum material performance: A vacuum hot press is the definitive choice for achieving the highest possible density, purity, and strength, especially for advanced ceramics, composites, and refractory metals.

- If your primary focus is high-volume, lower-cost production: For materials where some porosity is acceptable and specifications are less stringent, conventional pressureless sintering may be a more cost-effective approach.

- If your primary focus is process repeatability for critical components: The precise control over atmosphere, temperature, and pressure makes this technology ideal for applications where quality control and batch-to-batch consistency are non-negotiable.

Ultimately, choosing a vacuum hot press is an investment in unparalleled material quality and process control.

Summary Table:

| Advantage | Description |

|---|---|

| High Density | Achieves near-theoretical density (>99%) by eliminating porosity through pressure and vacuum. |

| Enhanced Purity | Prevents contamination and oxidation in a vacuum environment for cleaner materials. |

| Improved Mechanical Properties | Increases strength, hardness, and toughness by reducing stress concentrators. |

| Controlled Microstructure | Maintains fine grain size with lower temperature sintering for better material performance. |

| Precision and Repeatability | Ensures uniform results with automated controls for critical applications. |

| Safety and Efficiency | Operates with enhanced safety features and energy-efficient design, reducing environmental impact. |

Elevate your material processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored vacuum hot press sintering furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior density, purity, and performance. Contact us today to discuss how our solutions can optimize your processes and deliver unmatched results—reach out via our contact form for a personalized consultation!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What core functions do graphite molds serve? Essential Roles in Vacuum Hot Pressing Sintering of SiC/ZTA Ceramics

- How does an industrial-grade hot press sintering system benefit Al2O3/TiC/SiC(w) ceramics? Enhanced Material Density

- What is the application of hot press furnaces in ceramic processing? Achieve Superior Density and Strength

- How does vacuum hot pressing equipment enhance the matrix quality of diamond tools through improved wettability? Unlock Superior Diamond Retention

- What is the vacuum hot pressing technique? Achieve Maximum Density & Purity for Advanced Materials

- What are the advantages of using a Spark Plasma Sintering (SPS) system for UHTCs? Master Rapid Densification

- Why must hot press sintering equipment possess high vacuum environment control capabilities when preparing copper-based composites? Ensure Purity, Bonding, and Performance

- How does a vacuum press machine work in shaping metals? Achieve Precision Metal Forming with Uniform Pressure