Upon final sinter firing, zirconium dioxide transforms from a porous, chalk-like state into a fully dense ceramic with exceptional mechanical and physical properties. The most notable of these is a high flexural strength of approximately 900 MPa, achieved by sintering between 1350°C and 1550°C, making it one of the strongest and most reliable ceramics used in demanding applications.

Sintering is not merely a heating process; it is a controlled atomic transformation. It eliminates porosity to achieve near-total density, creating a stable polycrystalline structure that is the source of zirconia's signature strength and fracture toughness.

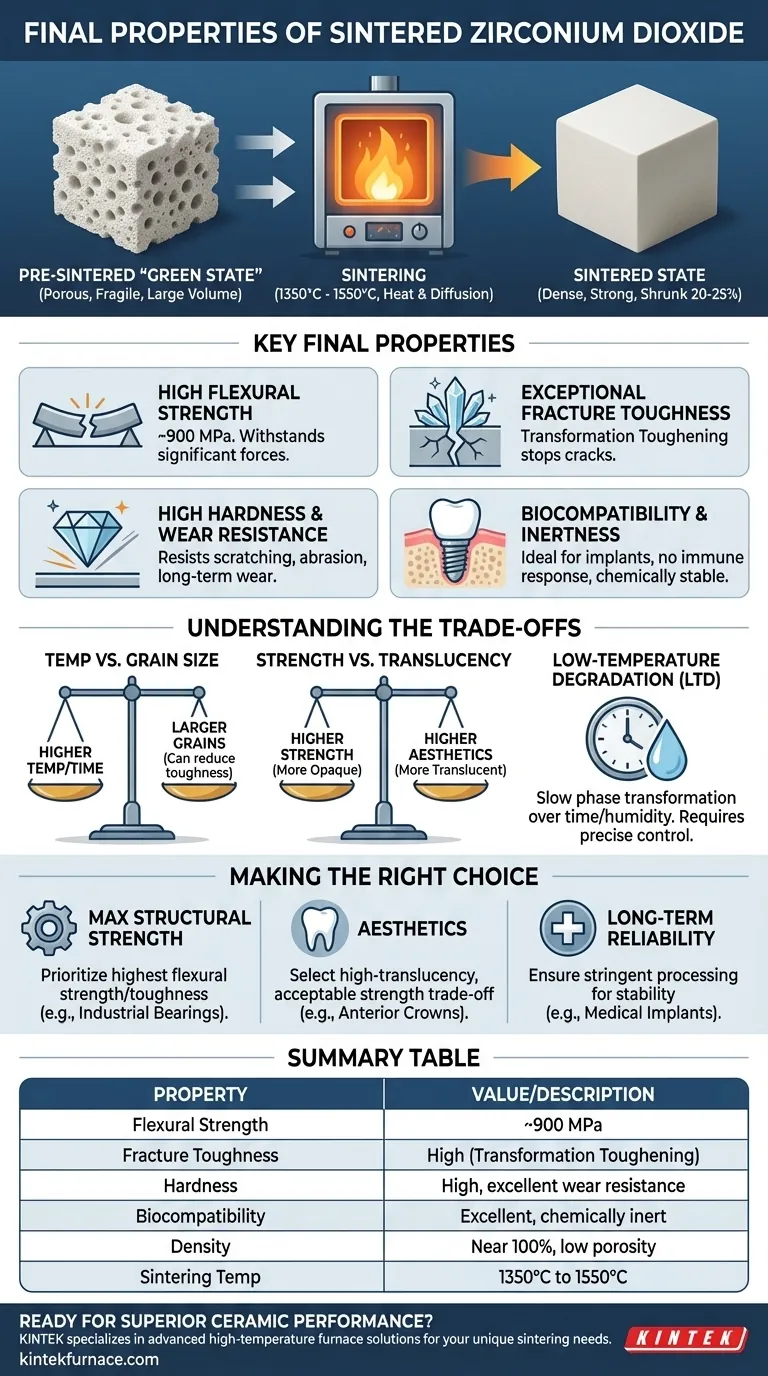

From "Chalk" to Ceramic: The Sintering Transformation

To understand the final properties, you must first understand the profound change that occurs during sintering. The material starts in one state and ends in a completely different one.

The Pre-Sintered "Green State"

Before firing, milled zirconia exists in a porous, partially bonded state often described as "chalk-like." At this stage, it is soft, fragile, and easy to shape but possesses none of its final strength. Its volume is also significantly larger than the final product.

The Role of Heat and Diffusion

Sintering heats the material to just below its melting point. At these high temperatures (1350°C to 1550°C), the atoms at the boundaries of the zirconia particles become mobile. They diffuse across the pores, effectively eliminating the voids and fusing the individual particles together.

The Result: A Dense, Polycrystalline Structure

This process shrinks the component by 20-25% and results in a solid, polycrystalline material that is nearly 100% dense. It is this final, non-porous structure that gives sintered zirconia its remarkable properties.

Key Final Properties of Sintered Zirconia

The dense microstructure created by sintering gives rise to a unique combination of characteristics not found in most other ceramics.

High Flexural Strength

Flexural strength measures a material's ability to resist bending before it breaks. A value of 900 MPa or higher is exceptionally strong, allowing zirconia to withstand the significant occlusal forces in dental restorations or the mechanical loads in industrial components.

Exceptional Fracture Toughness

This is zirconia's defining feature. It has a unique internal mechanism called transformation toughening. When a micro-crack begins to form, the stress at the crack's tip causes the local crystal structure to change. This transformation induces localized compressive stress that literally squeezes the crack shut, preventing it from spreading.

High Hardness and Wear Resistance

The dense, stable crystalline structure makes the surface extremely hard. This provides excellent resistance to scratching, abrasion, and long-term wear, ensuring the material maintains its form and function over time.

Biocompatibility and Chemical Inertness

Sintered zirconia is highly biocompatible and does not provoke an immune response, making it ideal for medical and dental implants. It is also chemically inert, meaning it will not corrode or react when exposed to bodily fluids or other chemicals.

Understanding the Trade-offs

Achieving the ideal properties is a balancing act. The final outcome is highly sensitive to the exact sintering protocol and material composition.

Sintering Temperature vs. Grain Size

Sintering at higher temperatures or for longer times can increase density, but it also causes the crystal grains to grow. Overly large grains can, in some cases, slightly reduce the material's fracture toughness and long-term stability.

Strength vs. Translucency

In dental applications, there is often a trade-off between strength and aesthetics. The strongest, most opaque forms of zirconia offer the highest flexural strength. Higher translucency versions, which are more aesthetically pleasing, often achieve this by modifying the composition in a way that slightly reduces the peak strength.

Low-Temperature Degradation (LTD)

Over many years, and in the presence of water or humidity, a slow phase transformation can occur on the zirconia's surface. This phenomenon, known as aging or LTD, can potentially create micro-roughness and reduce the material's strength over its lifespan. Proper manufacturing and precise sintering control are critical to minimizing this risk.

Making the Right Choice for Your Application

Your specific goal will determine which properties of zirconia are most critical.

- If your primary focus is maximum structural strength (e.g., long-span dental bridges, industrial bearings): Prioritize zirconia grades with the highest flexural strength and fracture toughness, even if they are more opaque.

- If your primary focus is aesthetics (e.g., anterior dental crowns): Select a high-translucency zirconia, understanding there is a small, clinically acceptable trade-off in absolute strength for a superior visual result.

- If your primary focus is long-term reliability (e.g., medical implants): Ensure the material has been processed according to stringent protocols to maximize stability and minimize any risk of low-temperature degradation.

Understanding these final properties empowers you to select and utilize this advanced material with precision and confidence.

Summary Table:

| Property | Value/Description |

|---|---|

| Flexural Strength | ~900 MPa |

| Fracture Toughness | High, due to transformation toughening |

| Hardness | High, excellent wear resistance |

| Biocompatibility | Excellent, chemically inert |

| Density | Near 100%, low porosity |

| Sintering Temperature | 1350°C to 1550°C |

Ready to achieve superior ceramic performance in your lab? KINTEK specializes in advanced high-temperature furnace solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our deep customization capabilities, we can tailor equipment to meet your unique sintering needs for zirconia and other materials. Contact us today to discuss how we can enhance your research and production processes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations