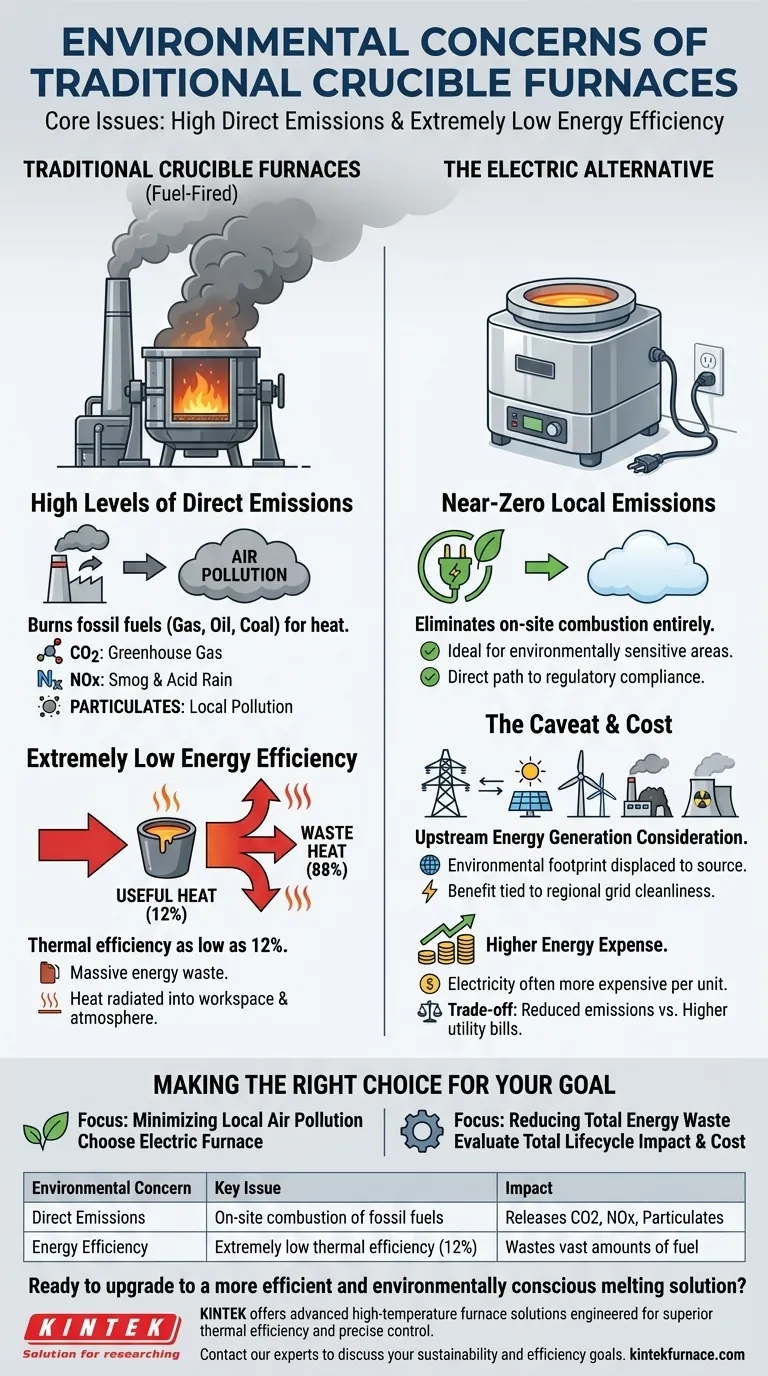

In short, traditional crucible furnaces pose significant environmental concerns due to two primary factors: high levels of direct emissions from fuel combustion and extremely low energy efficiency. These furnaces release pollutants directly into the atmosphere and waste a substantial amount of the energy they consume, creating both ecological and economic burdens.

The core issue with traditional, fuel-fired crucible furnaces isn't just the visible pollution they create, but the invisible waste. Their inefficiency means the vast majority of fuel burned is lost, compounding their environmental impact far beyond what comes out of the smokestack.

The Core Environmental Challenges

Traditional crucible furnaces, typically fired by gas, oil, or coal, are defined by inherent design characteristics that lead directly to negative environmental outcomes. Understanding these is key to evaluating their place in a modern operation.

High Levels of Direct Emissions

The most obvious environmental concern is air pollution. Because these furnaces burn fossil fuels for heat, they release products of combustion directly into the local environment.

This process generates harmful emissions, including carbon dioxide (CO2), nitrogen oxides (NOx), and other particulates. These pollutants contribute to smog, acid rain, and greenhouse gas accumulation, making these furnaces unsuitable for operations in areas with strict air quality regulations.

Extremely Low Energy Efficiency

A less visible but equally critical problem is profound inefficiency. Traditional crucible furnace designs can have thermal efficiency ratings as low as 12%.

This means for every 100 units of energy consumed from fuel, as few as 12 units are actually used to melt the metal inside the crucible. The remaining 88% is lost, primarily as waste heat radiated into the surrounding workspace and atmosphere. This massive energy waste represents a significant and unnecessary consumption of fossil fuels for the work being performed.

Understanding the Trade-offs: The Electric Alternative

The most common alternative, the electric crucible furnace, directly addresses the primary environmental failings of its traditional counterpart, but it comes with its own set of considerations.

The Benefit: Near-Zero Local Emissions

By using electricity as the power source, these furnaces eliminate on-site combustion entirely. This resolves the problem of direct, local emissions.

For facilities located in environmentally sensitive areas or facing regulatory pressure, the move to electric heating is often the most direct path to compliance.

The Caveat: Upstream Energy Generation

It is critical to remember that "zero emissions" applies only to the furnace's physical location. The overall environmental footprint is displaced to the source of electricity generation.

If the power grid relies heavily on coal or natural gas, the melting process still contributes to emissions, just at a different location. The true environmental benefit is therefore directly tied to the cleanliness of the regional energy grid.

The Cost: Higher Energy Expense

While more efficient than fuel-fired models, electric furnaces typically have higher direct energy costs. Electricity is often a more expensive utility per unit of energy (BTU or kWh) than natural gas or oil.

This creates a financial trade-off: reduced emissions and higher material efficiency versus potentially higher monthly utility bills.

Making the Right Choice for Your Goal

Evaluating these furnaces requires balancing environmental goals with operational realities. The best choice depends entirely on your primary objective.

- If your primary focus is minimizing local air pollution: An electric crucible furnace is the definitive choice, as it eliminates all on-site combustion emissions.

- If your primary focus is reducing total energy waste: The answer is more nuanced. You must compare the poor fuel efficiency of a traditional furnace against the total lifecycle impact and higher cost of an electric model, including how your electricity is generated.

Ultimately, a modern approach requires evaluating both the direct emissions at your facility and the total energy lifecycle of your chosen melting technology.

Summary Table:

| Environmental Concern | Key Issue | Impact |

|---|---|---|

| Direct Emissions | On-site combustion of fossil fuels (gas, oil, coal) | Releases CO2, NOx, and particulates, contributing to local air pollution and greenhouse gases. |

| Energy Efficiency | Extremely low thermal efficiency (as low as 12%) | Wastes vast amounts of fuel, increasing overall energy consumption and environmental footprint. |

Ready to upgrade to a more efficient and environmentally conscious melting solution?

KINTEK understands the critical balance between operational performance and environmental responsibility. Our advanced high-temperature furnace solutions, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, are engineered for superior thermal efficiency and precise control, helping you reduce waste and emissions.

Leveraging exceptional R&D and in-house manufacturing, we provide strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Contact our experts today to discuss how we can help you achieve your sustainability and efficiency goals.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Induction Melting Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity