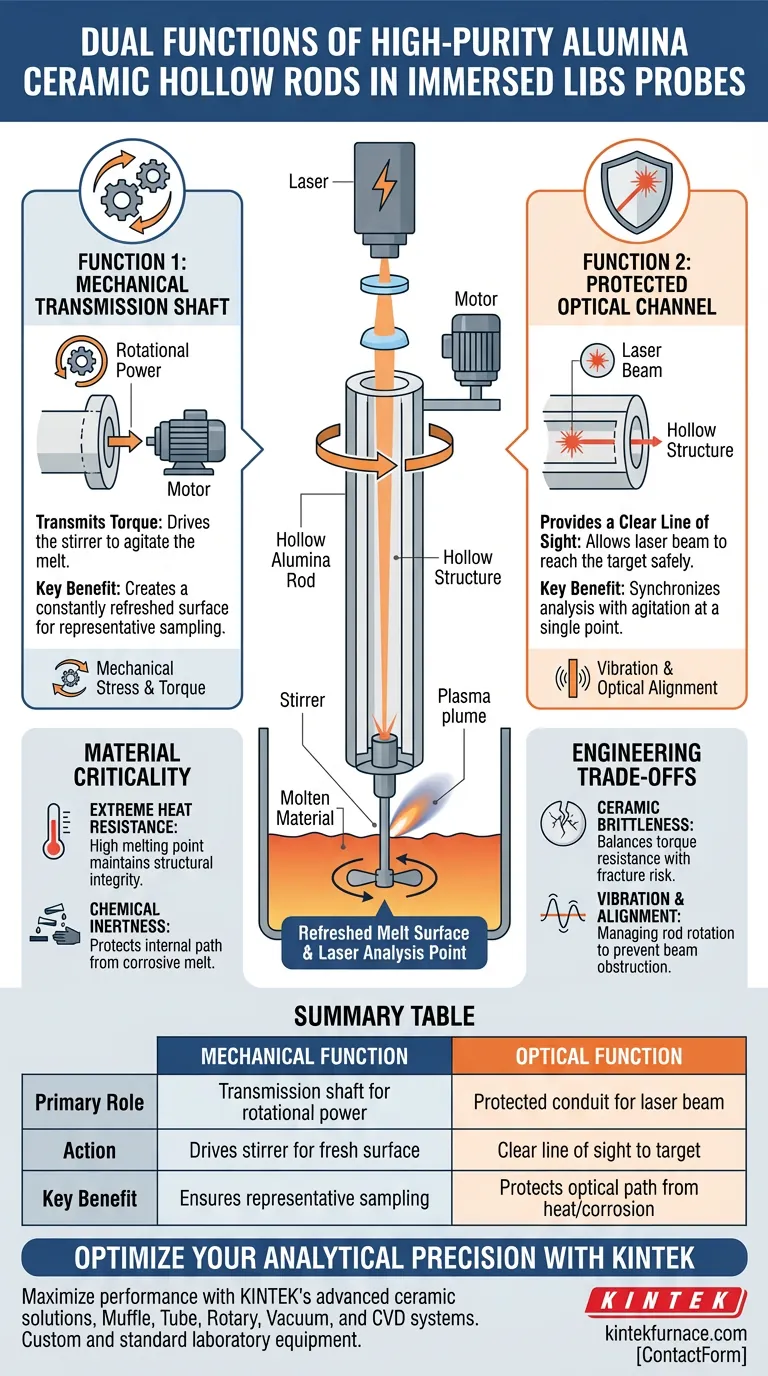

In the architecture of an immersed Laser-Induced Breakdown Spectroscopy (LIBS) probe, high-purity alumina ceramic hollow rods serve as the critical interface between delicate analysis equipment and the harsh industrial environment. These components perform two simultaneous functions: acting as a mechanical transmission shaft to drive agitation and serving as a shielded optical conduit for the laser path.

The hollow ceramic rod effectively solves the dual engineering challenge of delivering mechanical torque to refresh the molten surface while simultaneously providing a clear, protected path for the laser to analyze that specific surface.

The Mechanics of the Dual Function

To understand the probe's operation, one must look at how the rod integrates mechanical movement with optical precision.

Function 1: Mechanical Transmission Shaft

The first function of the rod is physical. It connects an external motor to a stirrer located inside the molten material.

By transmitting rotational power, the rod drives the stirrer to agitate the melt.

This agitation is crucial because it creates a constantly refreshed surface, ensuring the LIBS analysis is performed on representative material rather than a stagnant or contaminated top layer.

Function 2: Protected Optical Channel

The second function utilizes the rod's hollow geometry. The interior of the rod provides a clear line of sight from the laser source to the melt.

This hollow structure allows the high-energy LIBS laser beam to travel safely down the center of the shaft.

The beam is focused directly onto the fresh surface created by the stirrer, ensuring the analysis and the mechanical agitation are perfectly synchronized at the same physical point.

Why Material Choice is Critical

The environment within a melt is destructive to standard engineering materials. The choice of high-purity alumina is not arbitrary; it is a functional requirement for this dual-purpose design.

Withstanding Extreme Heat

The rod serves as a thermal barrier. Alumina is selected for its extremely high melting point, allowing it to maintain structural integrity while immersed.

It prevents the collapse of the internal channel, ensuring the laser path remains open even under intense thermal stress.

Chemical Defense

Beyond heat, the rod provides chemical inertness. It protects the internal optical path from the corrosive nature of the high-temperature melt.

Without this barrier, the optical components would degrade rapidly, rendering the probe inaccurate or inoperable.

Understanding the Engineering Trade-offs

While this dual-function design is efficient, it introduces specific engineering challenges that must be managed.

Mechanical Stress vs. Ceramic Brittleness

Using a ceramic rod as a driveshaft places it under torque. While alumina is hard, it can be brittle compared to metals.

The system relies on the rod being robust enough to transmit rotation to the stirrer without fracturing under the resistance of the viscous melt.

Vibration and Optical Alignment

Because the rod is rotating, it introduces the potential for vibration.

Since the laser beam must pass through the center of this moving part, any significant wobble or misalignment in the rod could obstruct the laser path or defocus the beam on the target surface.

Optimizing LIBS Probe Performance

When evaluating or designing LIBS systems using this technology, consider your specific operational priorities.

- If your primary focus is Data Accuracy: Ensure the rotational speed of the rod is sufficient to create a truly fresh surface without inducing vibrations that misalign the laser focus.

- If your primary focus is Equipment Longevity: Prioritize the purity and wall thickness of the alumina rod to maximize resistance against thermal shock and chemical corrosion in your specific melt type.

This dual-function approach streamlines the probe design, turning a single component into both the engine of agitation and the window of observation.

Summary Table:

| Feature | Mechanical Function | Optical Function |

|---|---|---|

| Primary Role | Transmission shaft for rotational power | Protected conduit for the laser beam |

| Action | Drives the stirrer to refresh the melt surface | Provides a clear line of sight to the target |

| Key Benefit | Ensures representative material sampling | Protects optical path from heat and corrosion |

| Material Criticality | Torque resistance and thermal stability | High melting point prevents channel collapse |

Optimize Your Analytical Precision with KINTEK

Maximize the performance of your LIBS probes and high-temperature systems with KINTEK’s advanced ceramic solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers high-purity alumina components, along with a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems.

Whether you need standard laboratory equipment or fully customizable high-temp furnaces tailored to your unique industrial needs, our team is ready to deliver the durability and precision your research demands.

Ready to upgrade your lab's capabilities? Contact us today to discuss your project requirements!

Visual Guide

References

- Younès Belrhiti, Amal Chabli. Mechanical stirring: Novel engineering approach for in situ spectroscopic analysis of melt at high temperature. DOI: 10.1016/j.heliyon.2024.e25626

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- What is the composition of DM Type Silicon Carbide Heating Elements? Discover High-Temp Reliability

- What are the applications of MoSi2 heating elements? Unlock High-Temp Solutions for Your Industry

- What are the advantages of MoSi2 heating elements in terms of temperature capability? Unmatched High-Temp Performance

- What are the key characteristics of silicon carbide heating rods? Discover High-Temp Durability & Efficiency

- What material is used for the crucible in the resistive heating evaporation process? Alumina for Purity & Performance

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What are the chemical properties of silicon carbide heating elements regarding oxidation? Maximize Lifespan with Controlled Oxidation

- What is the typical lifespan of 1700 type MoSi2 heating elements at different temperatures? Maximize Element Longevity