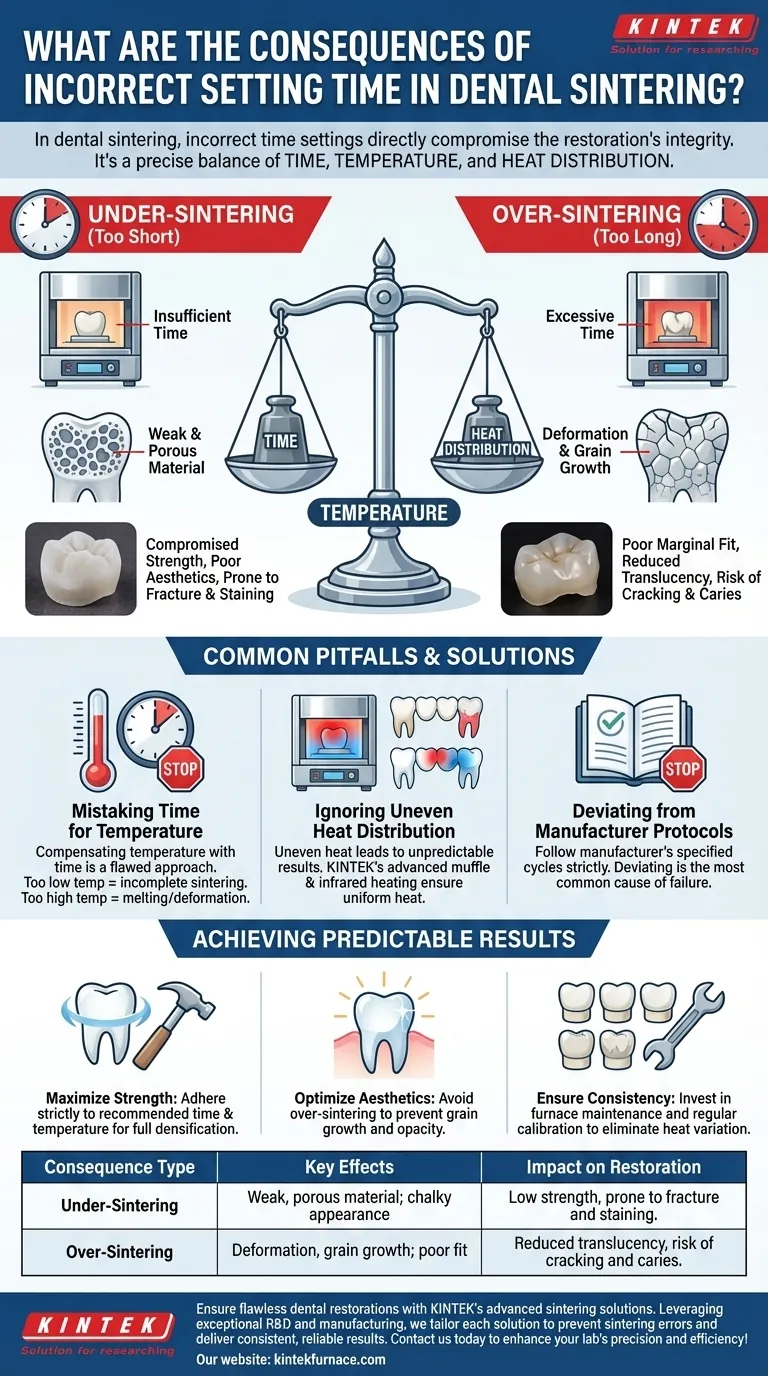

In dental sintering, incorrect time settings directly compromise the restoration's integrity. Setting the time too short results in under-sintering, leaving the material weak and porous. Conversely, setting the time too long causes over-sintering, leading to potential deformation, compromised fit, and poor aesthetics. This single parameter is critical for achieving the desired material properties.

Sintering is not just about time; it's a precise balance of time, temperature, and heat distribution. Viewing these as an interconnected system, rather than isolated settings, is the key to preventing restoration failures and achieving consistent, reliable results.

The Consequences of Under-Sintering

Under-sintering occurs when the restoration is not kept in the furnace for a sufficient duration at the correct temperature. This leaves the material in a partially fused, weakened state.

The Problem of Insufficient Time

When the sintering cycle is too short, the material particles do not have enough time to fully bond and densify. The process is halted before the material can reach its target physical properties.

Compromised Strength and Durability

This is the most critical consequence. An under-sintered restoration will have significantly lower flexural strength, making it brittle and highly prone to fracture under normal chewing forces.

Poor Aesthetics and Porosity

An under-sintered crown often appears chalky or overly opaque. The incomplete fusion leaves microscopic voids, increasing porosity which makes the restoration susceptible to staining over time.

The Dangers of Over-Sintering

Over-sintering happens when the material is exposed to heat for too long. While it may seem like "more is better," excessive time is just as damaging as insufficient time.

Deformation and Poor Marginal Fit

Excessive time in the furnace can cause the restoration to warp or shrink beyond its intended dimensions. This results in a poor marginal fit, creating gaps that invite microleakage, plaque accumulation, and secondary caries.

Grain Growth and Reduced Translucency

When materials like zirconia are held at high temperatures for too long, their crystalline grains grow larger. This excessive grain growth can increase opacity and reduce the material's natural translucency, harming the final aesthetic outcome.

Internal Stress and Cracking

While more commonly associated with high temperatures, extended sintering times can contribute to internal stresses. This can lead to the formation of micro-cracks that compromise the long-term stability of the restoration.

Common Pitfalls: It's More Than Just Time

Focusing only on the sintering time is a critical mistake. True quality control requires a holistic understanding of the entire firing process.

Mistaking Time for Temperature

A common error is attempting to compensate for an incorrect temperature setting by adjusting the hold time. This is a flawed approach that rarely succeeds.

If the temperature is too low, no amount of extra time will achieve full, proper sintering. If the temperature is too high, the material can melt or deform, and a shorter time will not prevent this damage.

Ignoring Uneven Heat Distribution

A furnace with poor heat distribution creates hot and cold spots, leading to uneven sintering within the same restoration. This is a hidden cause of many failures.

For example, one part of a bridge could be perfectly sintered while an abutment is under-sintered and weak, creating a critical point of failure. Technologies like QTK muffle technology or infrared heating are specifically designed to ensure uniform heat and prevent this.

Deviating from Manufacturer Protocols

Each dental material has a unique, scientifically validated sintering schedule. Deviating from the manufacturer's specified time and temperature cycle is the single most common cause of failure. Always treat these instructions as a strict requirement, not a guideline.

Achieving Predictable Sintering Results

To move from uncertainty to consistency, align your process with your primary goal for the restoration.

- If your primary focus is maximum strength and durability: Strictly adhere to the manufacturer's recommended time and temperature to ensure full, proper densification of the material.

- If your primary focus is optimal aesthetics and translucency: Avoid any form of over-sintering by ensuring both time and temperature do not exceed the specified limits, as this prevents grain growth and opacity.

- If your primary focus is consistent quality across all restorations: Invest in furnace maintenance and regular calibration to guarantee even heat distribution, eliminating the variable of hot/cold spots causing unpredictable results.

Mastering the sintering process comes from treating it as a precise science, not a matter of guesswork.

Summary Table:

| Consequence Type | Key Effects | Impact on Restoration |

|---|---|---|

| Under-Sintering | Weak, porous material; chalky appearance | Low strength, prone to fracture and staining |

| Over-Sintering | Deformation, grain growth; poor fit | Reduced translucency, risk of cracking and caries |

Ensure flawless dental restorations with KINTEK's advanced sintering solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability tailors each solution to your unique experimental needs, preventing sintering errors and delivering consistent, reliable results. Contact us today to discuss how we can enhance your lab's precision and efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision