At its core, a vacuum hot press sintering furnace is used to forge advanced materials by simultaneously applying intense heat and pressure in a controlled, oxygen-free environment. This process is critical for producing highly dense and pure components from materials like advanced ceramics, refractory metals, and powder composites for demanding applications in the aerospace, electronics, and research sectors.

The fundamental value of this technology is its ability to eliminate internal voids and prevent chemical contamination during material consolidation. By applying mechanical pressure while heating in a vacuum, these furnaces create materials with superior density, strength, and purity that are often impossible to achieve with conventional heat treatment alone.

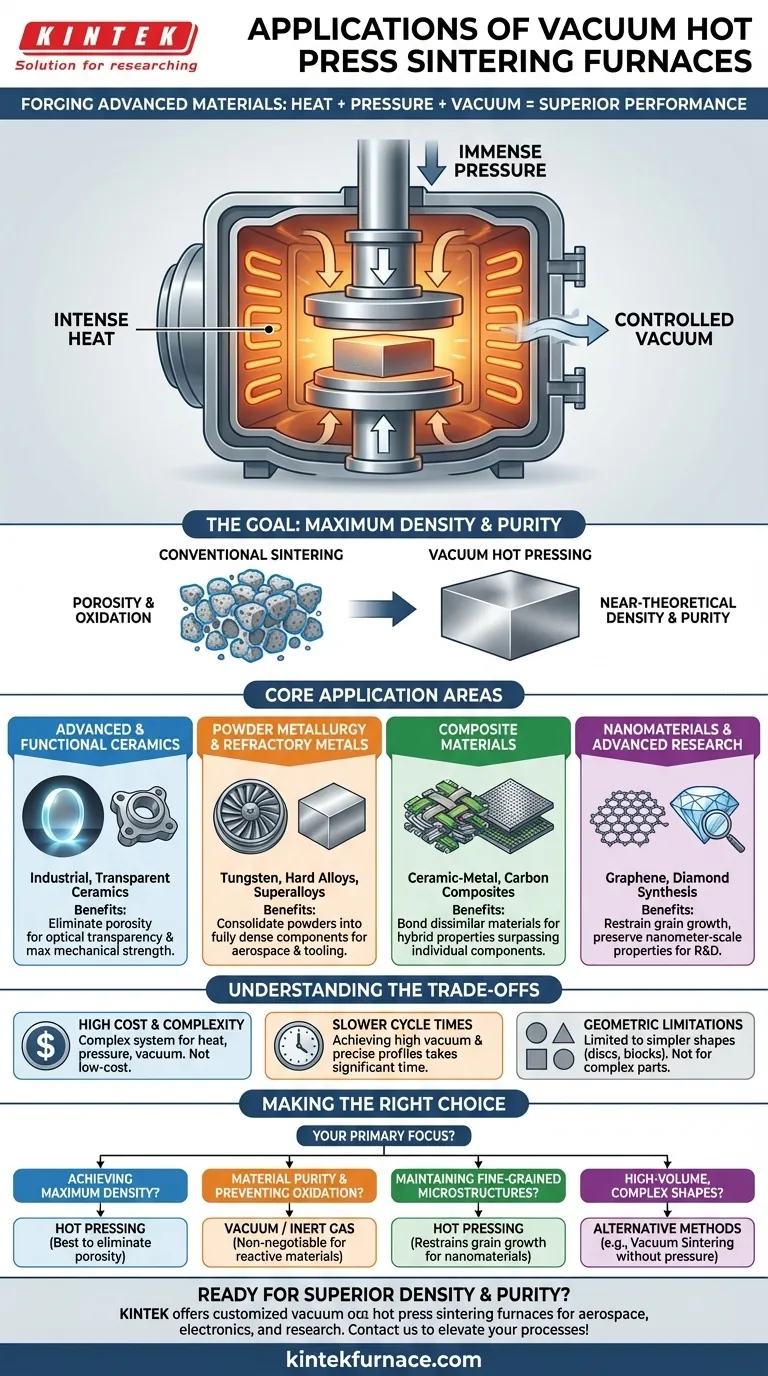

The Fundamental Goal: Achieving Maximum Density and Purity

To understand the applications, you must first understand the problem these furnaces solve. The goal of sintering is to take a collection of fine particles and fuse them into a solid, coherent mass.

The Role of Heat and Sintering

Sintering uses heat to encourage atoms to diffuse across the boundaries of adjacent particles, creating solid bonds. However, heating alone often leaves behind tiny voids, or porosity, which can significantly weaken the final material.

The Critical Role of Pressure

This is where the "hot press" aspect becomes essential. By applying immense mechanical pressure during heating, the furnace physically forces particles together, collapsing the pores that would otherwise remain. This process, known as consolidation, is key to achieving near-theoretical density.

The Decisive Role of Vacuum

Heating reactive materials in the open air causes oxidation, which contaminates the material and degrades its properties. By performing the process in a high vacuum or a protective inert gas atmosphere, the furnace removes oxygen and other reactive elements, ensuring the final product has exceptional purity.

Core Application Areas

The unique ability to combine heat, pressure, and a clean environment makes vacuum hot pressing indispensable for developing and producing a specific class of high-performance materials.

Advanced and Functional Ceramics

These furnaces are used to produce industrial ceramics, transparent ceramics, and other functional variants. The pressure is essential to eliminate the last traces of porosity, which is critical for achieving desired optical transparency or maximum mechanical strength.

Powder Metallurgy and Refractory Metals

Materials like tungsten, hard alloys, and superalloys are processed from powder form. Hot pressing consolidates these metal powders into fully dense blocks or simple shapes with mechanical properties that meet the extreme demands of aerospace engine components and high-wear tooling.

Composite Materials

Vacuum hot pressing is a primary method for fabricating ceramic-metal and carbon-composite materials. The furnace provides the ideal conditions to bond these dissimilar materials, creating a hybrid with combined properties that surpass those of its individual components.

Nanomaterials and Advanced Research

For researchers, a key advantage is the furnace's ability to restrain the growth of crystal grains. The combination of lower-than-melting-point temperatures and pressure allows for densification without letting the tiny nanometer-scale grains coarsen, preserving their unique properties. This makes it vital for R&D, graphene synthesis, and diamond synthesis.

Understanding the Trade-offs

While powerful, vacuum hot pressing is not a universal solution. Its benefits come with inherent limitations that make it suitable for specific challenges.

High Cost and Complexity

A system that manages high temperature, high pressure, and high vacuum simultaneously is complex and expensive to acquire, operate, and maintain. This is not a low-cost manufacturing method.

Slower Cycle Times

Achieving a high vacuum and executing a precisely controlled heating and cooling profile takes a significant amount of time. Compared to atmospheric furnaces, the throughput of a hot press is considerably lower.

Geometric Limitations

The need to apply uniform pressure means that hot pressing is typically limited to producing simpler geometries, such as discs, blocks, and cylinders. It is not well-suited for creating the highly complex shapes possible with methods like metal injection molding.

Making the Right Choice for Your Goal

Selecting the right process depends entirely on your material's end-use requirements.

- If your primary focus is achieving near-theoretical density: Hot pressing is the superior choice, as the applied pressure is the most effective way to eliminate internal porosity.

- If your primary focus is material purity and preventing oxidation: The vacuum or inert gas environment is non-negotiable, making this furnace ideal for reactive metals and advanced ceramics.

- If your primary focus is maintaining fine-grained microstructures: The precise control offered by hot pressing helps restrain grain growth, which is essential for developing advanced nanomaterials.

- If your primary focus is high-volume production of complex shapes: You should investigate alternative methods like vacuum sintering without pressure, which allows for more intricate geometries.

Ultimately, vacuum hot press sintering is the definitive solution when the performance and purity of your material cannot be compromised.

Summary Table:

| Application Area | Key Materials | Primary Benefits |

|---|---|---|

| Advanced Ceramics | Industrial, transparent ceramics | High density, strength, transparency |

| Powder Metallurgy | Tungsten, hard alloys, superalloys | Full density, extreme mechanical properties |

| Composite Materials | Ceramic-metal, carbon composites | Hybrid properties, strong bonding |

| Nanomaterials & Research | Graphene, diamond, fine-grained materials | Grain growth restraint, unique nanoscale properties |

Ready to achieve superior material density and purity for your lab? KINTEK specializes in advanced high-temperature furnace solutions, including vacuum hot press sintering furnaces, tailored for aerospace, electronics, and research sectors. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Contact us today to discuss how our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems can elevate your processes!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the mechanism of hot press? Achieve Full Densification for Advanced Materials

- What is a hot press used for? Fabricate Dense, High-Performance Materials

- What are the applications of hot pressing? Achieve Maximum Material Performance

- How do temperature, pressure, and vacuum affect material bonding and microstructure in vacuum hot pressing? Optimize for High-Performance Materials

- How does hot pressing work? Achieve Maximum Density and Strength for Advanced Materials