At its core, the DM Type Silicon Carbide (SiC) heating element is a versatile, general-purpose component used in a wide range of industrial furnaces. Its characteristic "dumbbell" or "dog bone" shape, with a central heating section and thickened cold ends for electrical connection, makes it suitable for common applications like metal heat treatment, sintering, and firing ceramics where reliable, high-temperature heating is required.

The most critical factor in choosing a Silicon Carbide heating element is its physical shape. While the base material is the same, the element's geometry—whether it's a general-purpose DM type or a specialized SC, W, or SCR type—dictates its ideal application and thermal performance within a furnace.

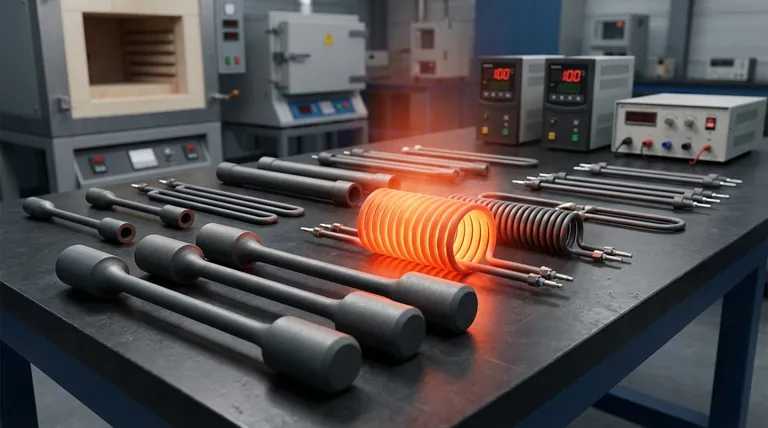

The Role of Element Shape in Heat Application

Silicon Carbide is a premier material for high-temperature heating elements due to its exceptional properties. It has a high hardness (9.5 Mohs), excellent thermal conductivity, and can operate at very high temperatures.

However, the raw material properties are only half the story. The physical design of the element is what tailors it to a specific industrial process. The shape determines how heat is distributed, how the element is mounted, and how it connects to a power supply.

DM Type: The General-Purpose Workhorse

The DM Type is defined by its hollow tubular heating section and solid, thickened ends. This design makes it a highly versatile and widely used element.

Its shape is ideal for straightforward furnace designs where elements are mounted through the furnace walls. The thickened ends remain cooler, providing a stable point for electrical connections outside the primary hot zone. Common uses include general-purpose lab furnaces, metal annealing, and ceramic firing.

SC Type: For Uniform Surface Heating

The SC Type is a single-piece element designed for consistent heating and minimal temperature variance across a large surface.

It is frequently used for bottom or side heating in large-scale industrial furnaces. Applications like metal hardening, tempering, and large ceramic kilns benefit from the SC type's ability to ensure spatial temperature uniformity is critical for consistent product quality.

W Type: For High-Power, Three-Phase Systems

The W Type, or three-phase element, features a unique shape that allows for direct connection to a three-phase power supply, simplifying wiring and power control.

This robust design is extensively used in processes that demand precise and uniform temperature, such as the production of float glass. Its efficiency also makes it a strong choice for certain electronics and chemical manufacturing applications.

SCR Type: For Precision and Advanced Control

SCR Type elements are engineered for the most demanding applications that require sophisticated thermal management and automated control.

They are favored in high-tech fields like aerospace component manufacturing, advanced electronics, and specialized industrial processes. These elements are particularly valuable where process controllers must make rapid and precise temperature adjustments.

Understanding the Trade-offs

Selecting an SiC element is not just about matching an application to a type; it involves balancing cost, performance, and operational complexity.

Specialization Comes at a Cost

General-purpose elements like the DM type are often more cost-effective and readily available. Specialized elements like the W or SCR types may have a higher upfront cost but deliver superior performance or efficiency for their intended niche, justifying the investment.

Atmosphere and Element Longevity

The operating environment inside the furnace significantly impacts the lifespan of any SiC element. While SiC is robust, certain chemical atmospheres can accelerate aging or cause contamination. The choice of element must account for the specific process gases and materials being heated.

Power Supply and Control Complexity

A simple DM or SC element setup may only require a basic power controller. In contrast, leveraging a W-type element requires a three-phase power supply, and an SCR-type element is best paired with an advanced, automated control system to unlock its full potential.

Making the Right Choice for Your Goal

Your final decision should be guided by the primary thermal requirement of your specific process.

- If your primary focus is general-purpose heating in a standard furnace: The DM type is your most versatile and cost-effective solution.

- If your primary focus is achieving absolute temperature uniformity across a large area: The SC type is designed specifically for this purpose.

- If your primary focus is building a high-power system on a three-phase supply: The W type provides an efficient and robust design for applications like float glass.

- If your primary focus is precision, automation, and sophisticated thermal management: The SCR type is the superior choice for high-tech and aerospace applications.

Ultimately, aligning the heating element's geometry with your specific operational goal is the key to optimizing furnace performance and ensuring reliable results.

Summary Table:

| Element Type | Key Applications | Primary Focus |

|---|---|---|

| DM Type | Metal heat treatment, sintering, ceramic firing, lab furnaces | General-purpose heating in standard furnaces |

| SC Type | Metal hardening, tempering, large ceramic kilns | Achieving absolute temperature uniformity across large areas |

| W Type | Float glass production, electronics, chemical manufacturing | High-power systems on three-phase supply |

| SCR Type | Aerospace component manufacturing, advanced electronics, specialized processes | Precision, automation, and sophisticated thermal management |

Optimize your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored heating elements, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how we can support your specific applications and drive superior results!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability