In the electronics industry, an atmosphere furnace is used to create a precisely controlled chemical environment during high-temperature manufacturing. This control is essential for preventing unwanted reactions like oxidation and for actively modifying material surfaces, ensuring the creation of reliable and high-performance electronic components.

The true benefit of an atmosphere furnace isn't just heating; it's the ability to manipulate the gaseous environment around a component. This prevents degradation and unlocks specific material properties that are impossible to achieve in open air, providing a crucial balance between precision, cost, and throughput.

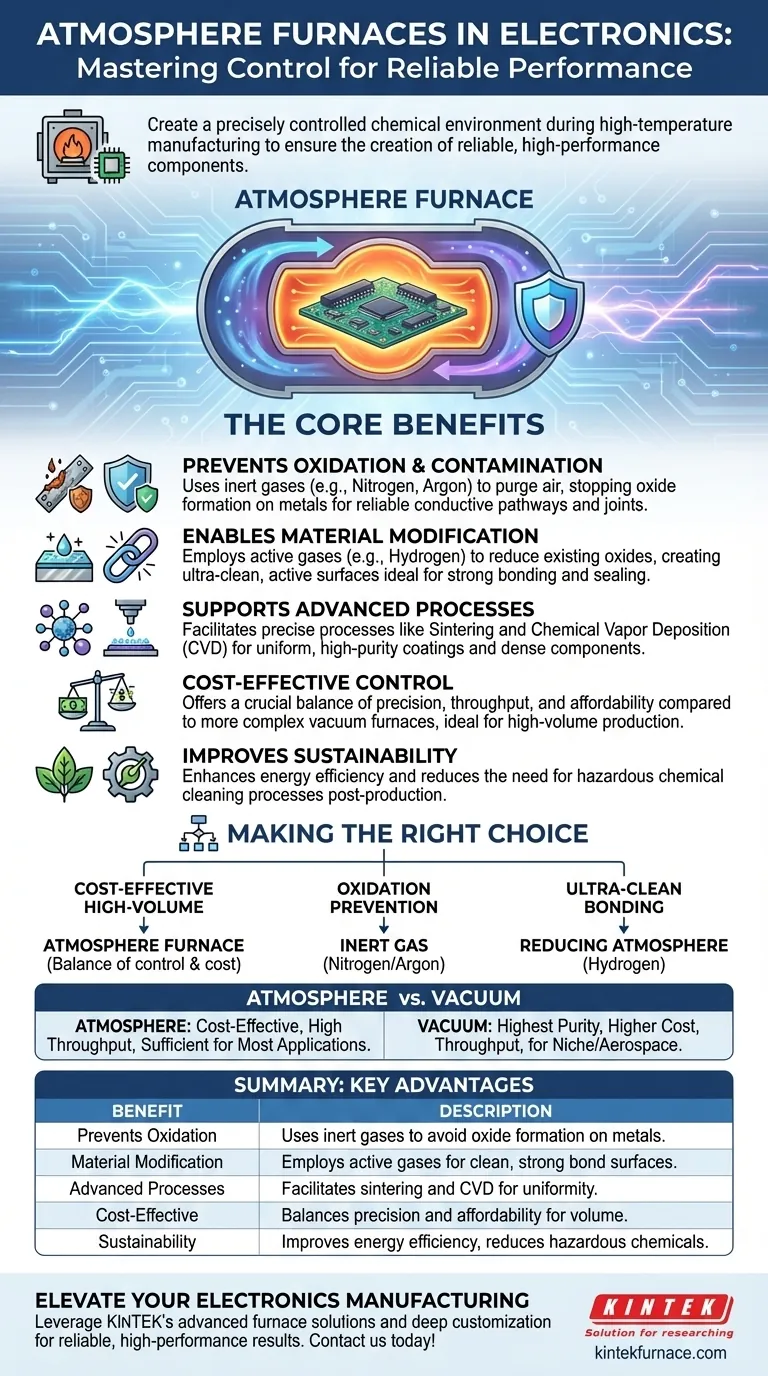

The Core Problem: Why Atmosphere Control is Essential

Modern electronics demand materials with highly specific electrical, thermal, and mechanical properties. Many of the manufacturing steps required to achieve this, such as annealing and sintering, involve extreme heat. Without a controlled atmosphere, this heat would destroy the very properties you are trying to create.

Preventing Oxidation and Contamination

At high temperatures, most metals react instantly with oxygen in the air, forming a brittle, non-conductive oxide layer. This is catastrophic for creating reliable solder joints, wire bonds, and conductive pathways.

An atmosphere furnace solves this by purging the processing chamber of air and replacing it with a specific gas. An inert gas like nitrogen or argon provides a neutral environment that prevents these destructive reactions from occurring.

Achieving Precise Material Properties

Atmosphere control goes beyond simple prevention. By using active gases, you can intentionally alter a material's surface chemistry.

For example, using a hydrogen atmosphere can actively reduce (remove) oxides that may already exist on a component's surface. This creates an ultra-clean, active surface that is ideal for subsequent brazing or sealing processes, resulting in stronger and more reliable bonds.

Enabling Advanced Manufacturing Processes

Processes like sintering powdered metals or ceramics into a solid component rely entirely on precise atmospheric and thermal control. The atmosphere dictates the final density, grain structure, and electrical characteristics of the finished part.

Similarly, Chemical Vapor Deposition (CVD), where a thin film is grown on a substrate, requires an extremely controlled environment to ensure the coating is uniform and has high purity. The atmosphere furnace provides the stable environment needed for these advanced techniques.

Understanding the Trade-offs

Choosing the right thermal processing equipment involves balancing precision, cost, and complexity. An atmosphere furnace occupies a critical middle ground.

Atmosphere vs. Standard Air Furnaces

For non-sensitive materials or processes where oxidation is irrelevant, a standard air furnace is simpler and cheaper.

However, for virtually all modern electronic components involving metallic conductors, semiconductors, or specialized ceramics, processing in air is not a viable option. The lack of control leads to inconsistent results and component failure.

Atmosphere vs. Vacuum Furnaces

A vacuum furnace, which removes nearly all atmosphere, offers the highest level of purity. It is the gold standard for applications where even trace amounts of gas are unacceptable.

However, vacuum furnaces are significantly more expensive to purchase and operate, have slower cycle times (due to pump-down), and are more complex to maintain. An atmosphere furnace provides a more cost-effective solution that delivers the necessary level of control for the vast majority of electronics applications.

Sustainability and Safety

Modern atmosphere furnaces contribute to more sustainable manufacturing by improving energy efficiency and reducing the need for hazardous chemical cleaning processes post-production.

The primary trade-off is the need for gas management infrastructure and safety protocols, especially when using flammable gases like hydrogen. This requires careful facility planning and operator training.

Making the Right Choice for Your Process

Your decision should be driven by the specific requirements of your material and the desired outcome of the heat treatment process.

- If your primary focus is cost-effective, high-volume production: An atmosphere furnace provides the best balance of environmental control, throughput, and operational cost.

- If your primary focus is preventing oxidation on sensitive metals: An inert nitrogen or argon atmosphere is the standard, reliable solution.

- If your primary focus is creating an ultra-clean, active surface for bonding: A reducing atmosphere containing hydrogen is the most effective choice.

- If your primary focus is achieving the absolute highest purity for niche research or aerospace-grade components: A vacuum furnace may be necessary, but you must justify the significant increase in cost and complexity.

Ultimately, mastering the atmosphere within your furnace is a direct lever for controlling the quality, reliability, and performance of your final electronic product.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Oxidation | Uses inert gases like nitrogen or argon to avoid oxide formation on metals, ensuring reliable conductive pathways. |

| Enables Material Modification | Employs active gases such as hydrogen to reduce oxides and create clean surfaces for stronger bonds. |

| Supports Advanced Processes | Facilitates sintering and CVD for uniform, high-purity coatings and dense components. |

| Cost-Effective Control | Offers a balance between precision and affordability compared to vacuum furnaces, ideal for high-volume production. |

| Improves Sustainability | Enhances energy efficiency and reduces need for hazardous post-processing chemicals. |

Ready to elevate your electronics manufacturing with precise atmosphere control?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for the electronics industry. Our product line, including Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, Vacuum Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental and production needs.

Whether you're focused on preventing oxidation, achieving ultra-clean surfaces, or optimizing cost and throughput, our expertise ensures reliable, high-performance results.

Contact us today to discuss how our atmosphere furnaces can enhance your component quality and efficiency!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios