At their core, vacuum furnaces are indispensable tools for manufacturing high-purity, high-performance components from metal powders and advanced alloys. Their primary applications are vacuum sintering in powder metallurgy and specialized heat treatment, melting, and brazing for reactive and high-temperature alloys used in critical industries like aerospace, medical, and energy.

The fundamental advantage of a vacuum furnace is not the heat, but the controlled environment. By removing atmospheric gases—most critically oxygen—it prevents unwanted chemical reactions, allowing for the creation of materials with a level of purity and structural integrity that is simply unattainable in open-air processes.

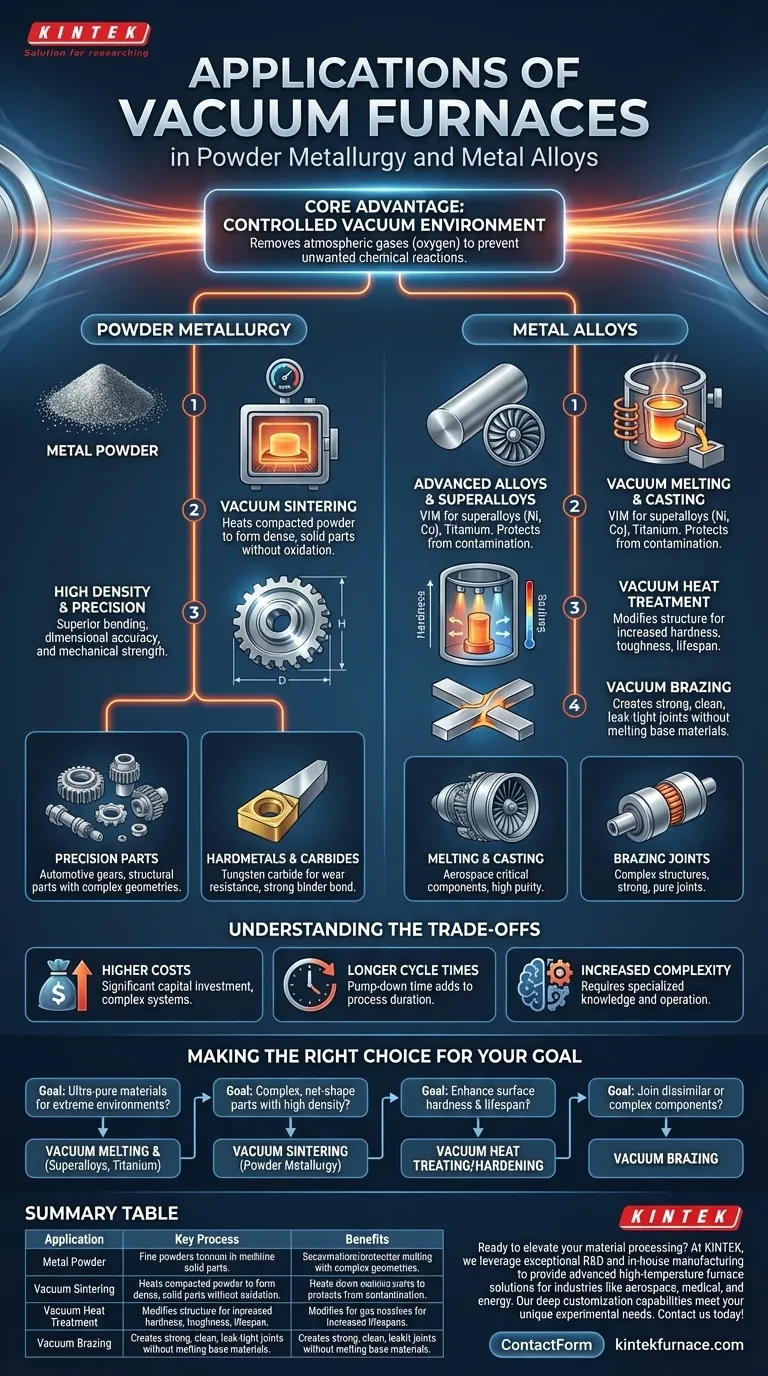

Why the Vacuum Environment is Critical

The decision to use a vacuum furnace is driven by the need to exert absolute control over the material's chemistry and microstructure during high-temperature processing.

Preventing Oxidation and Contamination

At elevated temperatures, most metals and alloys react aggressively with oxygen and other gases in the air. This oxidation can form unwanted surface layers, introduce impurities, and degrade the material's mechanical properties.

A vacuum furnace evacuates these reactive gases, creating a chemically inert environment. This ensures the final product is free from contamination and possesses the exact properties intended by its design.

Ensuring Purity and Uniformity

Beyond just preventing surface oxidation, the vacuum environment can also pull out dissolved gases, like hydrogen and nitrogen, from within the bulk metal itself. This degassing process is crucial for producing ultra-pure materials.

The result is a highly uniform grain structure and consistent density, leading to predictable and superior performance in demanding applications.

Key Applications in Powder Metallurgy

Powder metallurgy (PM) involves creating solid components from metal powders. Vacuum furnaces are essential for the final consolidation step.

Vacuum Sintering for High Density

Vacuum sintering is the process of heating compacted metal powders to just below their melting point, causing the particles to bond and form a dense, solid part.

Performing this in a vacuum prevents powder oxidation and promotes superior bonding, resulting in components with high density, improved mechanical strength, and excellent dimensional accuracy.

Precision Parts for Demanding Industries

This process is used to create high-precision metal parts with complex geometries, such as gears and structural components for the automotive industry. It minimizes distortion and ensures the part's final integrity is uncompromised.

Producing Hardmetals and Carbides

The tool industry relies on vacuum sintering to produce extremely hard and wear-resistant materials like tungsten carbide. The vacuum ensures a clean, strong bond between the hard carbide particles and the metallic binder (like cobalt).

Processing Advanced Metal Alloys

For many high-performance alloys, processing in a vacuum is not optional—it is a fundamental requirement.

Melting and Casting Superalloys

Superalloys (nickel-based or cobalt-based) and reactive alloys like titanium are the backbone of modern jet engines and gas turbines.

Vacuum induction melting (VIM) is used to melt these materials in a crucible, protecting them from oxygen contamination that would be catastrophic to their high-temperature performance. This ensures the highest possible purity and strength for critical components.

Heat Treatment for Enhanced Properties

Vacuum heat treating and hardening are used to modify the crystalline structure of alloys to achieve desired properties like increased hardness, toughness, and lifespan.

The process provides highly uniform heating and rapid, controlled cooling (gas quenching) without the risk of surface oxidation, improving the overall functionality of high-alloy steels and other metals.

Vacuum Brazing for Strong, Clean Joints

Vacuum brazing is a joining process used to create strong, leak-tight bonds between metal components without melting the base materials.

It is ideal for assembling complex structures like vacuum interrupters for the electrical industry or fuel injectors for engines. The vacuum ensures the brazing filler metal flows cleanly and wets the surfaces properly, creating a joint that is often as strong as the parent material.

Understanding the Trade-offs

While powerful, vacuum furnaces introduce their own set of considerations that differ from conventional atmospheric furnaces.

Higher Initial and Operational Costs

Vacuum furnaces represent a significant capital investment. The pumps, chambers, and control systems required to maintain a high vacuum are complex and expensive to purchase and maintain.

Longer Cycle Times

Achieving a deep vacuum is not instantaneous. The time required to pump down the chamber before the heating cycle can begin, known as the pump-down time, adds to the overall process duration compared to atmospheric furnaces.

Increased Process Complexity

Operating a vacuum furnace requires specialized knowledge. Technicians must understand vacuum principles, leak detection, and the specific outgassing characteristics of the materials being processed to ensure a successful and repeatable outcome.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace process should be directly tied to the required performance characteristics of the final component.

- If your primary focus is creating ultra-pure, defect-free materials for extreme environments (e.g., aerospace engines): Your best choice is vacuum melting and casting of superalloys or titanium.

- If your primary focus is producing complex, net-shape parts with high density and strength: Vacuum sintering of metal powders is the correct path.

- If your primary focus is enhancing the surface hardness and lifespan of an existing alloy component: Vacuum heat treating or hardening offers superior results by eliminating surface contamination.

- If your primary focus is joining dissimilar or complex components with a high-strength, pure joint: Vacuum brazing is the ideal solution.

Ultimately, mastering the vacuum environment is the key to unlocking the full potential of advanced engineering materials.

Summary Table:

| Application | Key Process | Benefits |

|---|---|---|

| Powder Metallurgy | Vacuum Sintering | High density, strength, purity, dimensional accuracy |

| Metal Alloys | Heat Treatment | Enhanced hardness, toughness, oxidation-free surfaces |

| Reactive Alloys | Vacuum Melting | Ultra-pure materials, prevents contamination |

| Component Joining | Vacuum Brazing | Strong, clean joints, leak-tight bonds |

Ready to elevate your material processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for industries like aerospace, medical, and energy. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our vacuum furnaces can enhance your lab's efficiency and deliver superior results for your powder metallurgy and alloy applications!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the technical advantages of using a vacuum drying oven? Protect WC-Co-Ni Powders from Oxidation

- What is the core role of a vacuum resistance melting furnace in the vacuum refining process of AM60 magnesium alloy? Mastering Magnesium's Volatile Nature

- What is another name for graphite furnace atomic absorption spectrometry? Discover ETAAS for Trace Metal Analysis

- What are the advantages and limitations of using vacuum furnaces? Unlock Precision Heat Treatment

- How are heating elements mounted in vacuum furnaces? Ensure Reliable, Uniform Heating

- Why is low-temperature calcination in a vacuum furnace necessary for Yb:CaF2 nanopowders? Achieve Optical Perfection

- How do advancements in graphite coatings improve vacuum furnace components? Enhance Purity and Durability

- What are the disadvantages of vacuum furnaces in terms of cost? High Initial and Ongoing Expenses Explained