At their core, the advantages of an electric heating rotary kiln center on unparalleled precision, automation, and environmental control. Compared to traditional fuel-fired systems, electric kilns offer a much higher degree of process stability by using resistance heating elements for indirect, uniform heating. This results in superior product quality, reduced operational demands, and a cleaner processing environment.

An electric rotary kiln's primary advantage is not just using a different energy source, but fundamentally shifting the operational paradigm from brute-force heating to precise, automated, and clean thermal processing. This allows for higher-value outputs with lower long-term operational costs and environmental impact.

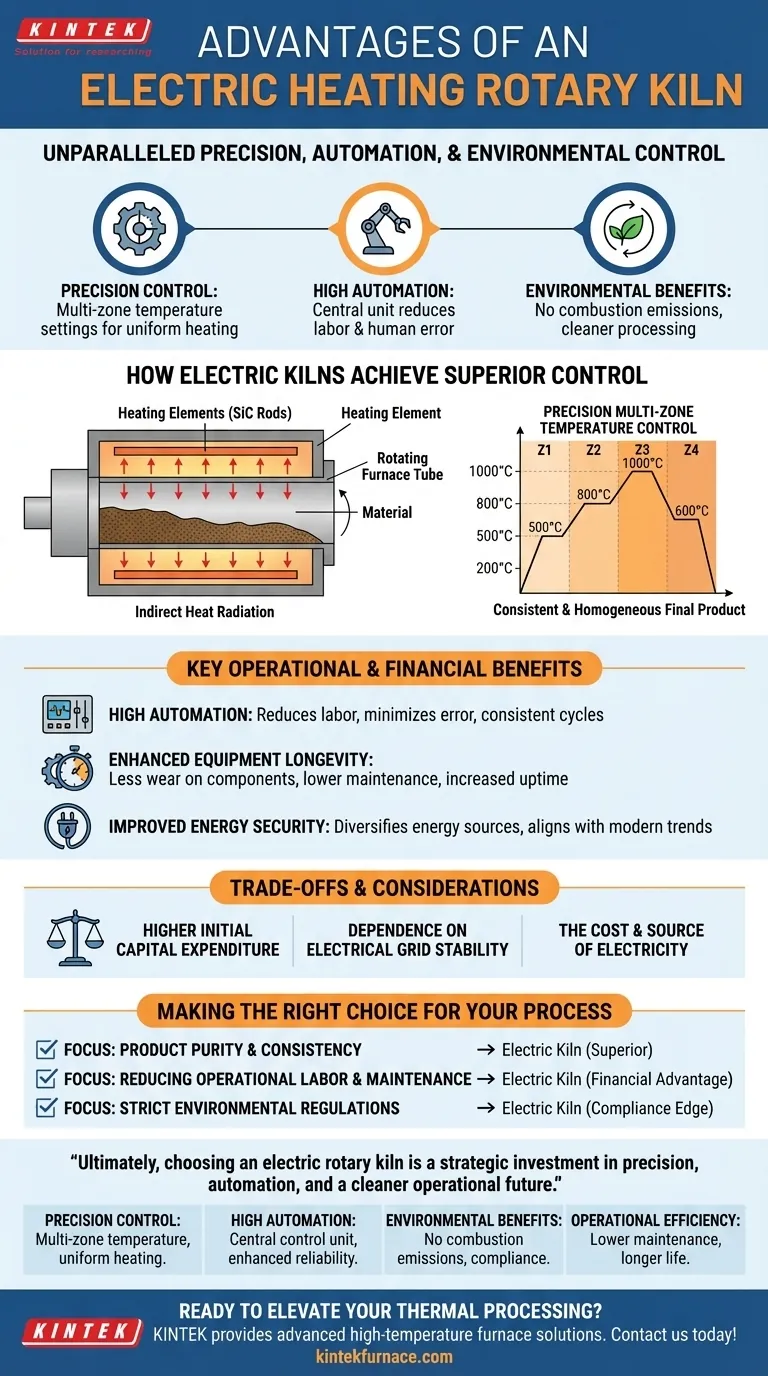

How Electric Kilns Achieve Superior Control

The unique benefits of an electric rotary kiln stem directly from its design, which replaces fuel combustion with electrical resistance heating. This architectural difference unlocks a new level of process management.

The Principle of Indirect Electric Heating

Electric rotary kilns are a type of indirect-fired kiln. The heating source, typically electrical resistance elements like silicon carbide rods, is located outside the rotating furnace tube.

These elements heat the kiln body, which in turn radiates heat to the material moving through the tube. This separation prevents any direct contact between the material and the heating source or combustion byproducts.

Precision Through Multi-Zone Temperature Control

Electric heating allows for exceptional temperature accuracy. The heating elements are often arranged in multiple, independently controlled temperature zones along the length of the kiln.

For example, a system might have four distinct heating groups, each with its own settable temperature. This allows operators to create a highly specific temperature profile that a material experiences as it travels through the kiln, ensuring optimal reaction conditions.

Unmatched Process Stability and Homogeneity

This precise thermal management, combined with the constant mixing action of the rotating kiln, results in exceptional final product homogeneity.

By eliminating the temperature fluctuations common in fuel-fired systems and ensuring every particle is exposed to uniform conditions, electric kilns reduce instances of uneven firing and produce a highly consistent final product.

Key Operational and Financial Benefits

Beyond product quality, the shift to electric heating delivers tangible benefits in daily operations, maintenance, and long-term strategy.

High Degree of Automation

Modern electric kilns are designed for a high degree of automation. The entire system, from the feeding device and kiln rotation to the multi-zone temperature profile and discharge, can be managed by a central control unit.

This significantly reduces labor requirements and minimizes the potential for human error, leading to more consistent and reliable production cycles.

Enhanced Equipment Longevity

Electric heating is less harsh on the kiln's structural components compared to direct fuel combustion. The controlled, even heating prolongs the life of the kiln tube and other critical parts.

This directly translates to lower maintenance costs and increased uptime over the life of the equipment.

Improved Energy Security

Relying on electricity can improve the security of your energy supply. It diversifies your energy sources away from potentially volatile fuel oil or natural gas markets.

Furthermore, adopting electrification aligns operations with modern industrial trends and provides valuable experience in deploying next-generation engineering solutions.

Understanding the Trade-offs and Considerations

While powerful, an electric rotary kiln is not the universal solution for every application. Objective analysis requires acknowledging its specific limitations.

Higher Initial Capital Expenditure

The sophisticated control systems and specialized heating elements associated with electric kilns often result in a higher upfront investment compared to simpler, fuel-fired alternatives.

Dependence on Electrical Grid Stability

Your operation becomes entirely dependent on a stable and robust electrical grid. Any power outages or brownouts will halt production unless you have invested in backup power systems.

The Cost and Source of Electricity

The primary operational cost shifts from fuel to electricity. You must evaluate your local electricity rates to determine the long-term financial viability. Additionally, the "green" benefit is only fully realized if your electricity is sourced from renewable or low-carbon power plants.

Making the Right Choice for Your Process

The decision to use an electric rotary kiln should be driven by your specific process requirements and strategic goals.

- If your primary focus is product purity and consistency: The unparalleled temperature control and indirect, non-contaminating heat of an electric kiln make it the superior choice.

- If your primary focus is reducing operational labor and maintenance: The high automation and reduced mechanical wear of electric kilns provide a clear long-term financial advantage.

- If your primary focus is meeting strict environmental regulations: The closed-system design and elimination of local combustion emissions give electric kilns a significant compliance edge.

Ultimately, choosing an electric rotary kiln is a strategic investment in precision, automation, and a cleaner operational future.

Summary Table:

| Advantage | Description |

|---|---|

| Precision Control | Multi-zone temperature settings for uniform heating and superior product consistency. |

| High Automation | Central control unit reduces labor and human error, enhancing reliability. |

| Environmental Benefits | No combustion emissions, cleaner processing, and compliance with regulations. |

| Operational Efficiency | Lower maintenance costs, longer equipment life, and improved energy security. |

Ready to elevate your thermal processing with precision and efficiency? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how our electric heating rotary kilns can enhance your lab's performance and sustainability!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control