At its core, the primary advantage of Plasma-Enhanced Chemical Vapor Deposition (PECVD) over traditional thermal CVD is its ability to operate at significantly lower temperatures. This is achieved by using plasma to energize the chemical reaction instead of high heat, which unlocks the ability to coat thermally sensitive substrates while often achieving higher deposition rates and more uniform films.

The fundamental difference is the energy source. Thermal CVD uses intense heat to break down precursor gases, while PECVD uses an energy-efficient plasma. This decouples the deposition process from high temperatures, making it a more versatile and often more cost-effective solution for modern materials.

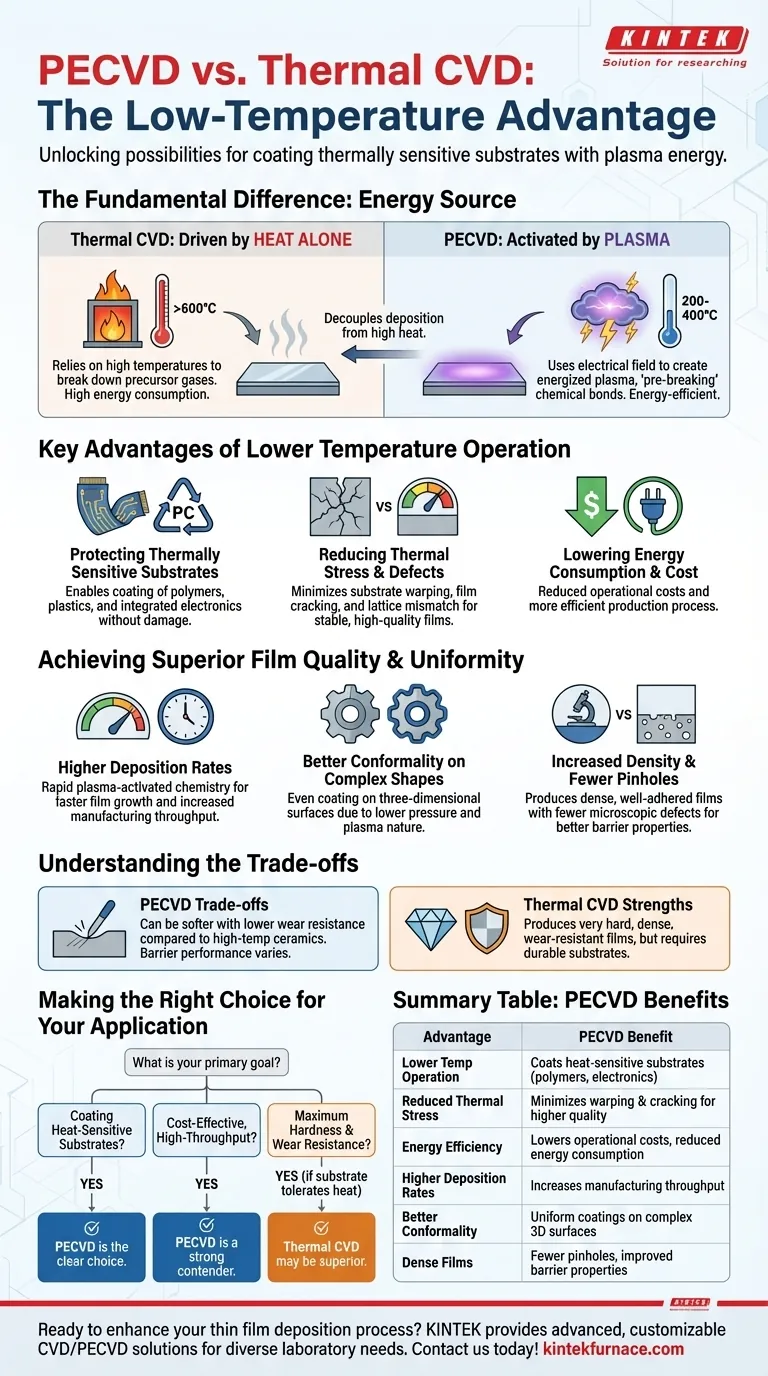

The Fundamental Difference: Energy Source

To understand the advantages of PECVD, you must first understand how it differs from thermal CVD at a process level. The choice of energy source dictates the capabilities and limitations of each method.

Thermal CVD: Driven by Heat Alone

Traditional thermal CVD relies exclusively on high temperatures, often exceeding 600°C, to provide the necessary activation energy. This heat forces the precursor gases to decompose and react on the substrate surface, forming the desired thin film.

PECVD: Activated by Plasma

PECVD introduces an electrical field to create a plasma, a highly energized state of matter. This plasma effectively "pre-breaks" the chemical bonds in the precursor gases at a much lower bulk temperature (typically 200-400°C), creating highly reactive species that then deposit onto the substrate.

Key Advantages of Lower Temperature Operation

The ability to operate at low temperatures is not just an incremental improvement; it is a transformative capability that fundamentally changes what is possible in thin film deposition.

Protecting Thermally Sensitive Substrates

This is the most significant advantage of PECVD. Materials like polymers, plastics, and many integrated electronic devices cannot withstand the extreme heat of thermal CVD. PECVD makes it possible to deposit high-quality films on these temperature-sensitive substrates without damaging or destroying them.

Reducing Thermal Stress and Defects

High temperatures create thermal stress, which can cause the substrate to warp or the deposited film to crack upon cooling. This temperature difference can also lead to lattice mismatch between the substrate and the film, introducing defects. PECVD's low-temperature process dramatically minimizes these issues, resulting in more stable, higher-quality films.

Lowering Energy Consumption and Cost

Heating a reaction chamber to the high temperatures required by thermal CVD consumes a significant amount of energy. By operating at lower temperatures, PECVD reduces energy consumption, leading to lower operational costs and a more efficient production process.

Achieving Superior Film Quality and Uniformity

Beyond temperature, PECVD offers distinct advantages in the quality and consistency of the final film, especially on complex geometries.

Higher Deposition Rates

In many cases, the plasma-activated chemistry of PECVD can proceed more rapidly than thermally-driven reactions. This allows for faster film growth, increasing manufacturing throughput.

Better Conformality on Complex Shapes

PECVD typically operates at lower pressures than atmospheric pressure CVD. This, combined with the nature of the plasma, allows the reactive gas species to coat complex, three-dimensional surfaces more evenly, resulting in a more uniform and conformal coating.

Increased Density and Fewer Pinholes

The lower process temperature helps produce films that are dense, well-adhered, and have fewer microscopic defects like pinholes. This is critical for applications requiring strong barrier properties or electrical insulation.

Understanding the Trade-offs

No technology is without limitations. While powerful, PECVD is not a universal solution, and its films have different properties than those produced by high-temperature methods.

Film Hardness and Wear Resistance

Because PECVD films are deposited at lower temperatures, they can be softer and have lower wear resistance compared to the very hard, dense ceramic films often produced by high-temperature thermal CVD.

Barrier Performance

While PECVD films are dense, their barrier performance against moisture or gases can sometimes be weaker than specialized polymers like Parylene or films deposited under different conditions. The final performance is highly dependent on the specific precursors and plasma parameters used.

Process Complexity and Contaminants

The use of plasma introduces additional process variables that must be controlled. Furthermore, some precursor gases, particularly halogenated ones, can pose environmental or health concerns if not handled properly.

Making the Right Choice for Your Application

The decision between PECVD and thermal CVD depends entirely on your substrate material and the desired properties of the final film.

- If your primary focus is coating heat-sensitive substrates (like polymers or electronics): PECVD is the clear and often only choice due to its low-temperature process.

- If your primary focus is achieving maximum hardness and wear resistance on a durable substrate: High-temperature thermal CVD may produce a superior film, provided the substrate can tolerate the intense heat.

- If your primary focus is cost-effective, high-throughput manufacturing of uniform films: PECVD is a strong contender due to its higher deposition rates and lower energy requirements.

Ultimately, selecting the right deposition technology requires a clear understanding of your specific engineering goals and material constraints.

Summary Table:

| Advantage | PECVD Benefit |

|---|---|

| Lower Temperature Operation | Enables coating of heat-sensitive substrates like polymers and electronics |

| Reduced Thermal Stress | Minimizes substrate warping and film cracking for higher quality |

| Energy Efficiency | Lowers operational costs with reduced energy consumption |

| Higher Deposition Rates | Increases manufacturing throughput with faster film growth |

| Better Conformality | Provides uniform coatings on complex 3D surfaces |

| Dense Films | Results in fewer pinholes and improved barrier properties |

Ready to enhance your thin film deposition process? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're working with heat-sensitive substrates or need tailored CVD solutions, we can help you achieve superior results. Contact us today to discuss how our expertise can benefit your specific application!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- What are the applications of PECVD? Unlock Low-Temperature Thin-Film Deposition

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties