In industrial applications, Microwave Plasma Chemical Vapor Deposition (MPCVD) provides a decisive edge by enabling the creation of high-purity, high-quality thin films and crystalline materials like diamond. Its primary advantages are superior process control, scalability for mass production, and the ability to produce materials with exceptional physical properties, leading to enhanced product performance and reduced long-term operational costs.

The core value of MPCVD in an industrial context is its unique ability to merge laboratory-grade material quality with the practical demands of manufacturing. It delivers exceptional purity and performance in a stable, reproducible, and scalable process, making it a strategic choice for producing next-generation components.

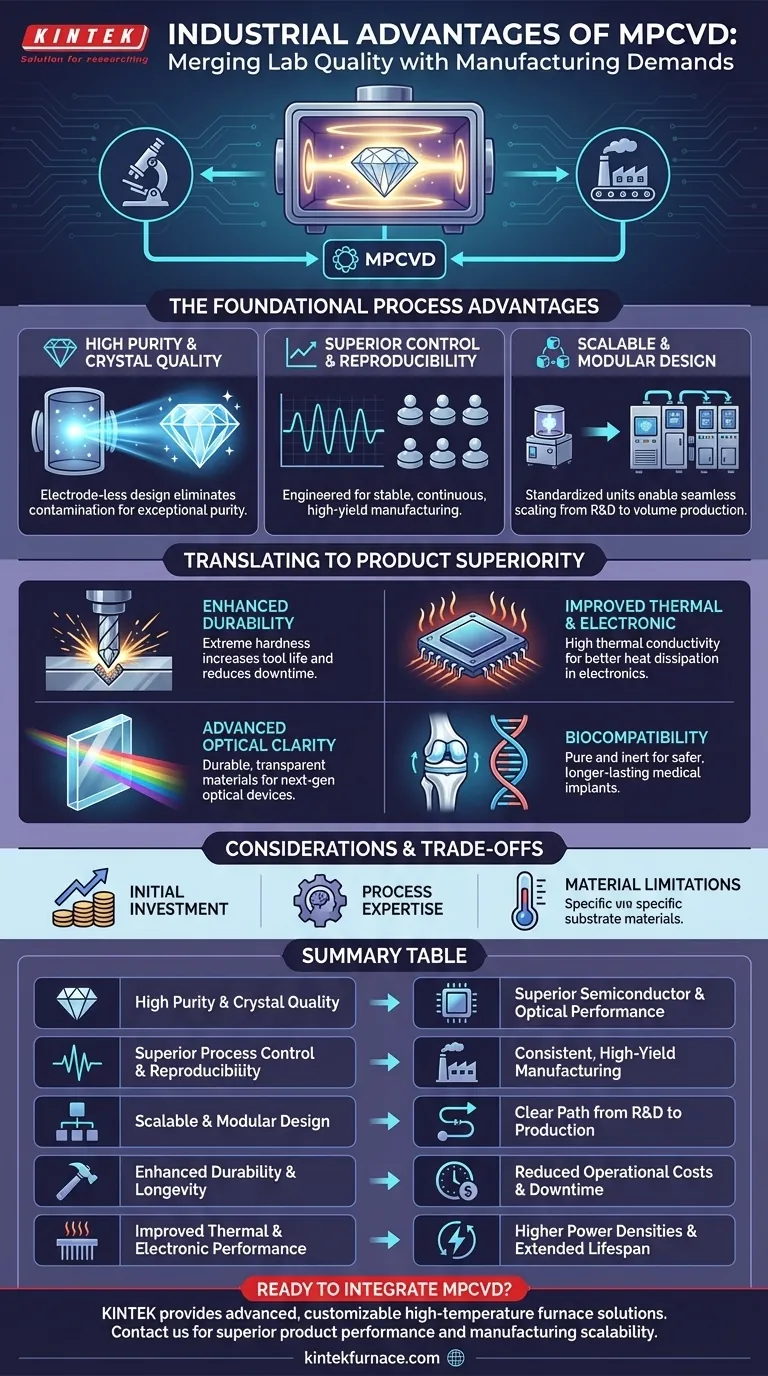

The Foundational Advantages of the MPCVD Process

The strengths of MPCVD begin with the fundamentals of the technology itself. Unlike older methods, its design directly addresses the core industrial requirements for quality and consistency.

High Purity and Crystal Quality

The MPCVD process is electrode-less, meaning the microwave energy is coupled directly into the gas chamber without physical electrodes. This design choice is critical as it eliminates a major source of contamination, ensuring the resulting films are exceptionally pure.

This purity is essential for achieving the theoretical performance limits of materials like diamond, which is vital for advanced semiconductor and optical applications.

Superior Process Control and Reproducibility

Industrial manufacturing demands stability. MPCVD systems are engineered for stable and reproducible deposition over extended periods.

This allows for continuous, long-duration operation without a degradation in film quality, ensuring that the first component produced is identical to the thousandth. This level of control is fundamental for high-yield manufacturing.

Scalability and Modular Design

MPCVD technology is inherently modular and scalable. Systems are often built with standardized microwave power units (e.g., 1-2 kW) that can be combined or upgraded.

This design allows a company to start with a smaller research setup and scale up to production on larger substrates without completely re-engineering the core process, offering a clear path from R&D to high-volume manufacturing.

Translating Process Strengths into Product Superiority

These process advantages directly translate into tangible performance gains across a wide range of industrial products. The quality of the material created by MPCVD enables devices and components to perform at a higher level.

Enhanced Durability and Longevity

For applications like cutting tools and wear-resistant coatings, the extreme hardness of MPCVD diamond is a key benefit.

This results in significantly increased tool life, more precise cutting edges, and improved efficiency. The direct economic impact is reduced downtime for tool changes and lower overall manufacturing costs.

Improved Thermal and Electronic Performance

MPCVD-grown diamond has exceptionally high thermal conductivity. This makes it a superior material for heat sinks and thermal management in high-power electronics.

By dissipating heat more effectively, MPCVD components extend device lifespan and allow electronics to operate at higher power densities. This is crucial for advancements in semiconductors and power devices.

Advanced Optical Clarity

The high purity and perfect crystal structure created by MPCVD result in materials with excellent optical properties. This is leveraged to create diamond optical windows that are durable and transparent across a wide spectrum of light.

These materials are also used to improve brightness and resolution in next-generation optical displays.

Biocompatibility for Medical Devices

The purity and inertness of MPCVD films make them highly biocompatible.

When used as coatings on medical implants or surgical tools, they enhance biocompatibility and significantly reduce wear, leading to safer and longer-lasting medical devices.

Understanding the Trade-offs and Considerations

While powerful, implementing MPCVD is a strategic decision that requires careful consideration of its operational context. It is not a universally simple drop-in replacement for all deposition techniques.

Initial Capital Investment

High-performance MPCVD systems represent a significant upfront capital investment. The precision engineering, microwave generators, and vacuum systems are complex and costly compared to more conventional coating technologies.

Requirement for Process Expertise

Achieving optimal results is not automatic. The process requires a deep understanding of plasma physics and chemistry to tune the deposition parameters for a specific material and substrate. This often requires specialized expertise and a dedicated process development phase.

Substrate and Material Limitations

The MPCVD process is incredibly versatile but not universally applicable without adaptation. The high temperatures involved can limit the types of substrate materials that can be used, and each new application may require significant research to optimize gas mixtures and process conditions.

Making the Right Choice for Your Goal

Adopting MPCVD depends entirely on your strategic priorities. Its benefits align with specific long-term goals for product performance and manufacturing capability.

- If your primary focus is ultimate product performance: MPCVD is a leading choice for creating materials with the highest possible purity, hardness, and thermal conductivity.

- If your primary focus is manufacturing scalability: The modular design of MPCVD provides a clear, low-risk pathway from initial R&D to high-volume industrial production.

- If your primary focus is reducing long-term operational costs: The enhanced longevity of MPCVD-coated tools and the improved efficiency of components can deliver a strong return on investment by minimizing downtime and replacement needs.

Ultimately, MPCVD empowers industries to move beyond incremental improvements and manufacture components that redefine the standards of performance and reliability.

Summary Table:

| Key Advantage | Industrial Impact |

|---|---|

| High Purity & Crystal Quality | Enables superior performance in semiconductors and optical devices. |

| Superior Process Control & Reproducibility | Ensures consistent, high-yield manufacturing over long production runs. |

| Scalable & Modular Design | Facilitates a clear path from R&D to high-volume production. |

| Enhanced Durability & Longevity | Increases tool life and reduces operational costs in cutting and wear applications. |

| Improved Thermal & Electronic Performance | Allows higher power densities and extended lifespan in electronics. |

Ready to integrate MPCVD technology into your manufacturing process?

KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including specialized MPCVD systems. Our deep customization capabilities ensure the system is precisely tailored to your unique material and production requirements, whether you are scaling from R&D or optimizing for high-volume output.

Contact us today to discuss how our expertise can help you achieve superior product performance and manufacturing scalability. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What are the operational benefits of using a CVD Tube Furnace? Enhance Precision and Efficiency in Your Lab

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- What is the process for synthesizing transition metal dichalcogenides (TMDs) using CVD tube furnaces? Master High-Quality Thin Film Growth

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What are the key design features of a CVD Tube Furnace? Optimize Your Material Synthesis with Precision