At its core, induction melting offers a fundamentally different way to process metal, delivering significant advantages in efficiency, quality, speed, and safety over traditional fuel-fired or arc furnaces. The technology uses a powerful electromagnetic field to generate heat directly within the metal itself, eliminating the need for external heating elements or combustion and providing an unparalleled level of process control.

The primary advantage of induction melting is not just one feature, but its ability to simultaneously improve product quality, reduce operational costs, and create a safer work environment. It represents a strategic shift from a brute-force heating process to a precise, controllable, and highly efficient manufacturing tool.

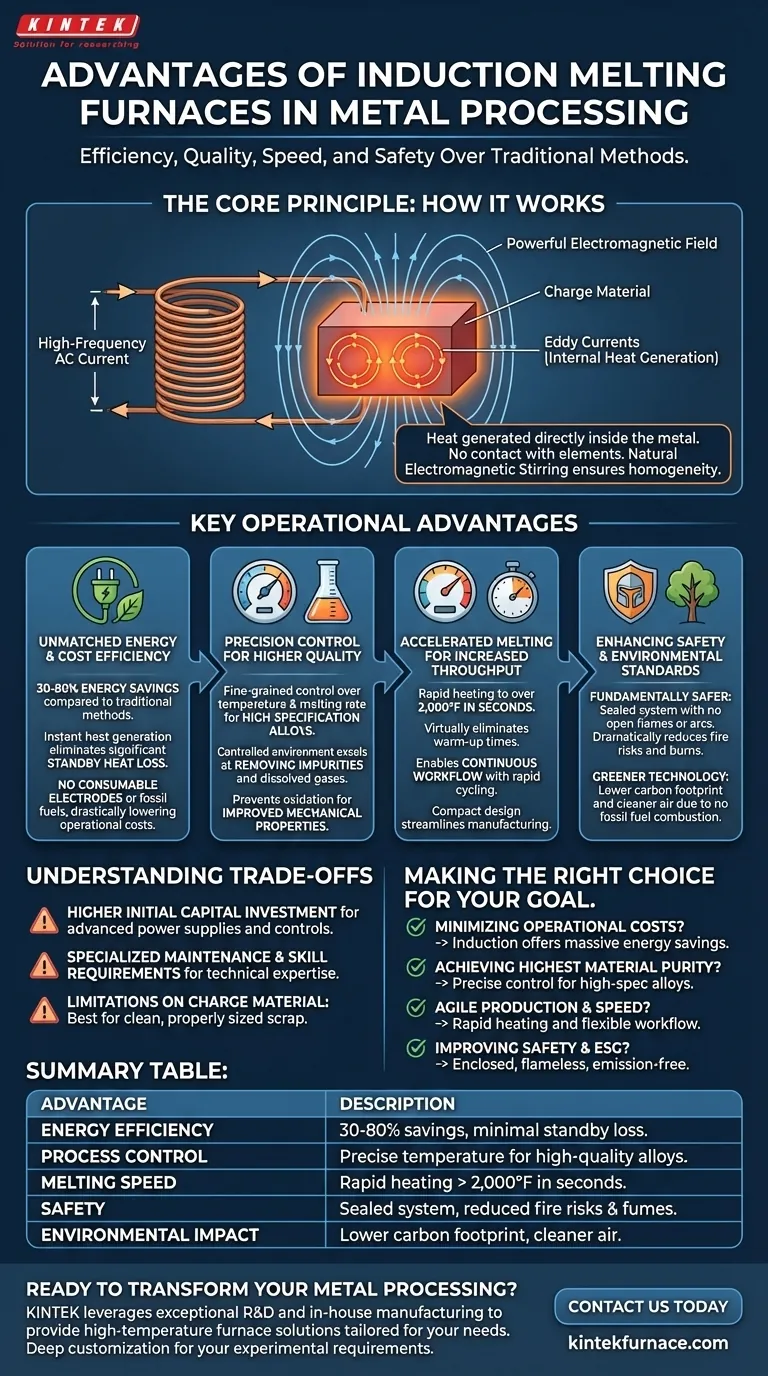

The Core Principle: How Induction Generates Superior Results

Induction furnaces operate on the principle of electromagnetic induction. By passing a high-frequency alternating current through a copper coil, a powerful and rapidly changing magnetic field is created. When conductive material like metal is placed within this field, it induces electrical currents (eddy currents) that generate precise and intense heat directly inside the charge material.

A Contained and Controlled Process

This method of heating from within is inherently cleaner and more controllable than external heating methods.

Because the heat is generated internally, there is no contact between the metal and a heating element or flame. This minimizes the risk of contamination and allows for melting within a sealed, and even vacuum, environment.

The process also creates a natural stirring action within the molten bath. This electromagnetic stirring ensures a homogenous mix, uniform temperature, and helps bring impurities to the surface where they can be removed.

Key Operational Advantages

The unique physics of induction heating translates directly into measurable benefits for foundries and metal processors. These advantages impact everything from the bottom line to the quality of the final product.

Unmatched Energy and Cost Efficiency

Induction furnaces are exceptionally energy-efficient, with some systems realizing 30-80% energy savings compared to traditional methods.

Heat is generated instantly and only where it is needed—in the metal itself. This eliminates the significant standby heat loss associated with keeping a conventional furnace at temperature.

Furthermore, the process requires no consumable electrodes or fossil fuels, which drastically lowers daily operational costs and removes the safety risks tied to fuel handling and storage.

Precision Control for Higher Metallurgical Quality

The ability to precisely manage power input gives operators fine-grained control over temperature and melting rate. This precision is critical for producing high-specification alloys.

Induction systems excel at removing dissolved gases and non-metallic impurities. The controlled environment, especially in vacuum induction furnaces, prevents oxidation and contamination from atmospheric gases like oxygen and nitrogen.

This results in a cleaner metal with improved mechanical properties, better structural integrity, and reduced shrinkage porosity in finished castings.

Accelerated Melting for Increased Throughput

Induction furnaces can heat metal to over 2,000°F in less than a second, virtually eliminating warm-up and wait times.

This rapid cycling capability allows for a continuous workflow, as the system cools down quickly and is immediately ready for the next melt. This contrasts sharply with the batch processing delays inherent in traditional furnaces.

The compact, self-contained design also means furnaces can be placed directly on the production floor, reducing material handling and streamlining the entire manufacturing process.

Enhancing Workplace Safety and Environmental Standards

Beyond operational performance, induction melting provides a major upgrade in creating a safer and more sustainable workplace.

A Fundamentally Safer Operating Environment

Induction furnaces operate as a sealed system without open flames, arcs, or dangerously hot external elements. This design dramatically reduces the risk of fires and severe burns.

The process also contains harmful emissions, leading to a significant reduction in operator exposure to toxic fumes and radiant heat compared to cupola or arc furnaces.

A Greener, More Sustainable Process

The high energy efficiency and elimination of fossil fuels make induction melting an inherently greener technology.

Reduced energy consumption directly lowers a facility's carbon footprint. The absence of combustion by-products also means cleaner air quality both inside and outside the plant.

Understanding the Trade-offs

While the advantages are compelling, adopting induction technology requires a clear-eyed assessment of its challenges. No technology is a universal solution.

Higher Initial Capital Investment

The most significant hurdle is often the upfront cost. Induction furnaces, with their advanced power supplies (like IGBT systems) and control electronics, typically require a larger initial capital investment than simpler, traditional furnace types.

Maintenance and Skill Requirements

Maintaining a high-frequency induction system requires specialized technical expertise. Troubleshooting power electronics and control systems is more complex than the mechanical maintenance of a conventional furnace.

Limitations on Charge Material

Induction furnaces perform best with relatively clean and properly sized charge materials. Heavily contaminated scrap or very large, bulky pieces can reduce efficiency and may require pre-processing, unlike some traditional furnaces that can handle a wider variety of inputs.

Making the Right Choice for Your Goal

Selecting a melting technology depends entirely on your primary operational drivers. Induction offers a powerful solution, but its value is most pronounced when aligned with specific business objectives.

- If your primary focus is minimizing operational costs: Induction is the definitive choice due to its massive energy savings and elimination of fuel and electrode consumption.

- If your primary focus is achieving the highest material purity: The precise control and vacuum capabilities of an induction furnace are essential for producing aerospace, medical, and other high-specification alloys.

- If your primary focus is agile production and speed: The rapid heating and cooling cycles of induction enable a flexible, on-demand workflow that traditional batch furnaces cannot match.

- If your primary focus is improving workplace safety and ESG metrics: The enclosed, flameless, and emission-free nature of induction melting offers a transformative improvement in workplace conditions and environmental impact.

Ultimately, investing in induction melting is a strategic decision to modernize your process for greater precision, efficiency, and safety.

Summary Table:

| Advantage | Description |

|---|---|

| Energy Efficiency | Achieves 30-80% energy savings with minimal standby heat loss. |

| Process Control | Enables precise temperature and melting rate for high-quality alloys. |

| Melting Speed | Rapid heating to over 2,000°F in seconds for increased throughput. |

| Safety | Sealed system reduces fire risks, burns, and toxic fume exposure. |

| Environmental Impact | Lower carbon footprint and cleaner air from no fossil fuel use. |

Ready to transform your metal processing with advanced induction melting solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions tailored for your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to boost efficiency, quality, and safety in your operations!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More