For processes demanding absolute purity and precision, an indirect-fired rotary kiln offers unparalleled advantages. Its core benefit is the complete separation of the material being processed from the heat source and its combustion gases. This design ensures precise temperature control, prevents product contamination, and allows for processing within a tightly controlled atmosphere, making it ideal for high-value or sensitive materials.

The fundamental choice to use an indirect-fired rotary kiln is a strategic one: prioritizing absolute product integrity and process control over the higher thermal efficiency offered by direct-fired systems. It is the definitive solution when the material cannot be exposed to combustion byproducts.

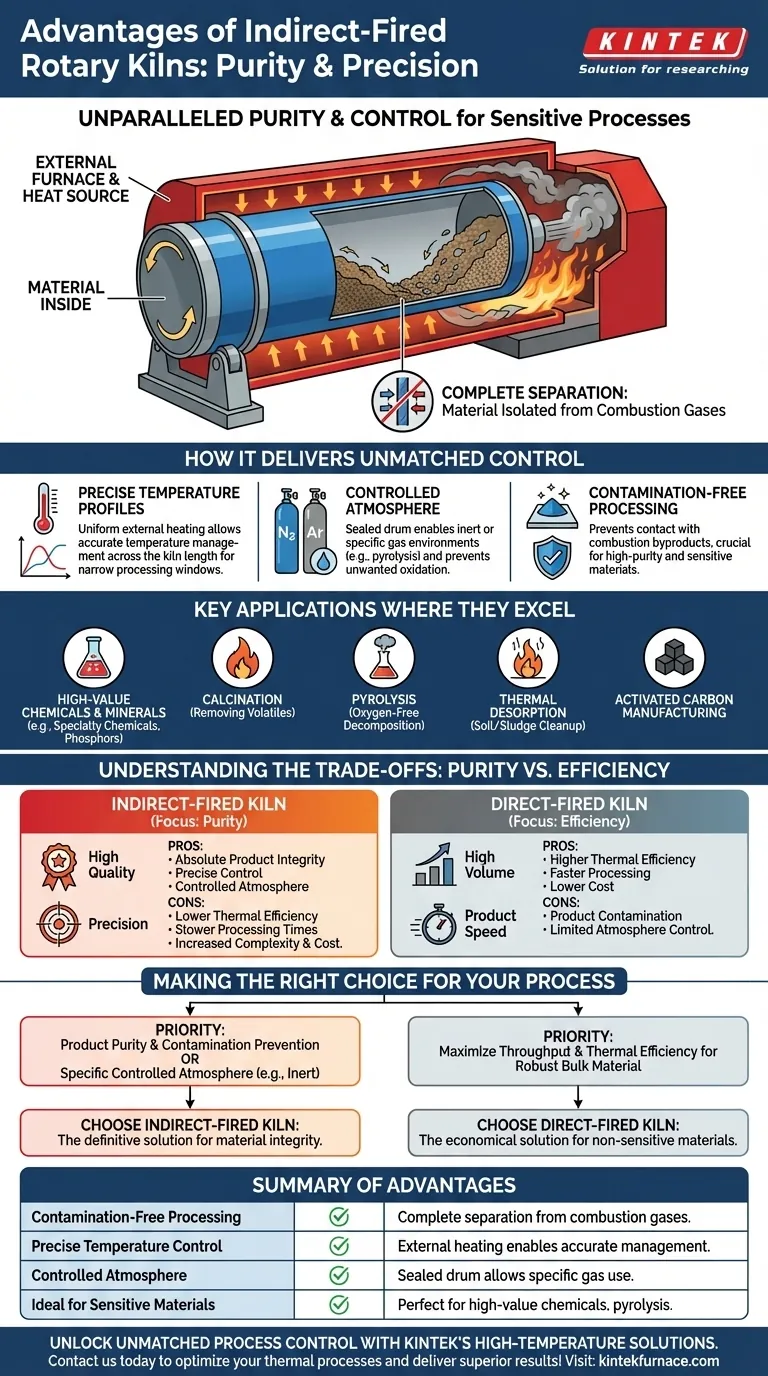

How Indirect Firing Delivers Unmatched Process Control

The unique design of an indirect-fired kiln is the source of its primary advantages. Unlike direct-fired kilns where the flame and material mix, this system isolates the two, creating a highly controlled environment.

The Principle of External Heating

An indirect-fired rotary kiln consists of a rotating drum enclosed within a stationary furnace or heating chamber. The external furnace heats the outside of the rotating drum shell. Heat is then transferred by conduction through the drum wall to the material tumbling inside.

This mechanical separation is the key. Because no combustion gases enter the drum, the processing atmosphere can be managed with exceptional precision.

Achieving Precise Temperature Profiles

With the heat source being external, the temperature can be applied and controlled very evenly across the shell's surface. This allows for extremely accurate temperature management along the entire length of the kiln, which is critical for materials with a narrow processing window or those requiring a specific heating curve to achieve desired chemical or physical changes.

Maintaining Atmosphere Integrity

The sealed nature of the rotating drum allows for the introduction of specific gases to create a controlled atmosphere. This is essential for processes like pyrolysis, which requires an oxygen-free (inert) environment, or for reactions that require a specific gas to proceed correctly. This prevents unwanted oxidation or side-reactions that would otherwise compromise the final product.

Key Applications Where Indirect Kilns Excel

The specific benefits of indirect firing make these kilns indispensable in several industries where material quality is paramount.

Processing High-Value, Sensitive Materials

Indirect kilns are the standard for high-purity, high-value materials that would be damaged or contaminated by direct flame contact. Examples include specialty chemicals, phosphors, titanates, and zinc oxide, where even trace impurities from combustion can ruin the product's performance.

Advanced Thermal Processes

Processes that rely on precise chemical transformations in a controlled environment are ideal for indirect kilns. These include:

- Calcination: Removing chemically bound water or volatiles without introducing contaminants.

- Pyrolysis: Thermally decomposing organic material in the absence of oxygen.

- Purification: Driving off specific impurities at controlled temperatures.

- Thermal Desorption: Removing contaminants from soils or sludges without combusting them.

Mineral and Chemical Industries

In mineral processing, indirect kilns are used for materials like bauxite, phosphate ore, and silica sand to achieve specific phase changes or purity levels. They are also vital in manufacturing activated carbon, where the atmosphere and temperature must be meticulously controlled to create the desired porous structure.

Understanding the Trade-offs: Purity vs. Efficiency

While the advantages are significant, they come with clear and important trade-offs. The decision to use an indirect kiln must weigh these factors carefully.

Lower Thermal Efficiency

Heating a material through a thick metal wall is inherently less efficient than exposing it to a direct flame. This means indirect-fired kilns typically consume more energy per unit of product compared to direct-fired systems, leading to higher fuel costs.

Slower Processing and Longer Heating Times

The indirect method of heat transfer is slower. As a result, materials require a longer residence time within the kiln to reach the target temperature. This can lead to lower overall throughput compared to a direct-fired kiln of a similar size.

Increased Complexity and Cost

The design, featuring a kiln inside a furnace, is more complex and expensive to build. The external furnace and the high-alloy materials often required for the rotating shell add to both the initial capital investment and the long-term maintenance costs.

Making the Right Choice for Your Process

The selection between a direct and indirect kiln is not about which is "better," but which is correct for your specific goal.

- If your primary focus is product purity and preventing contamination: An indirect-fired kiln is the definitive choice, as it completely isolates the material from combustion gases.

- If your primary focus is processing in a specific, controlled atmosphere (e.g., inert): The sealed design of an indirect kiln is non-negotiable for processes like pyrolysis or handling oxygen-sensitive materials.

- If your primary focus is maximizing throughput and thermal efficiency for a robust bulk material: A direct-fired kiln is likely the more economical and faster solution, provided the material can tolerate direct flame contact.

Ultimately, selecting an indirect-fired kiln is a strategic decision to prioritize material integrity and process precision over raw thermal efficiency.

Summary Table:

| Advantage | Description |

|---|---|

| Contamination-Free Processing | Complete separation of material from combustion gases prevents product contamination. |

| Precise Temperature Control | External heating enables accurate temperature management for narrow processing windows. |

| Controlled Atmosphere | Sealed drum allows use of specific gases (e.g., inert) for oxidation-free reactions. |

| Ideal for Sensitive Materials | Perfect for high-value chemicals, minerals, and processes like pyrolysis and calcination. |

Unlock Unmatched Process Control with KINTEK's High-Temperature Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. For applications demanding absolute purity and precision—such as processing sensitive materials or conducting pyrolysis—our indirect-fired rotary kilns offer contamination-free heating, precise temperature profiles, and controlled atmospheres to protect your product integrity. Don't compromise on quality; contact us today to discuss how our tailored solutions can optimize your thermal processes and deliver superior results!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity