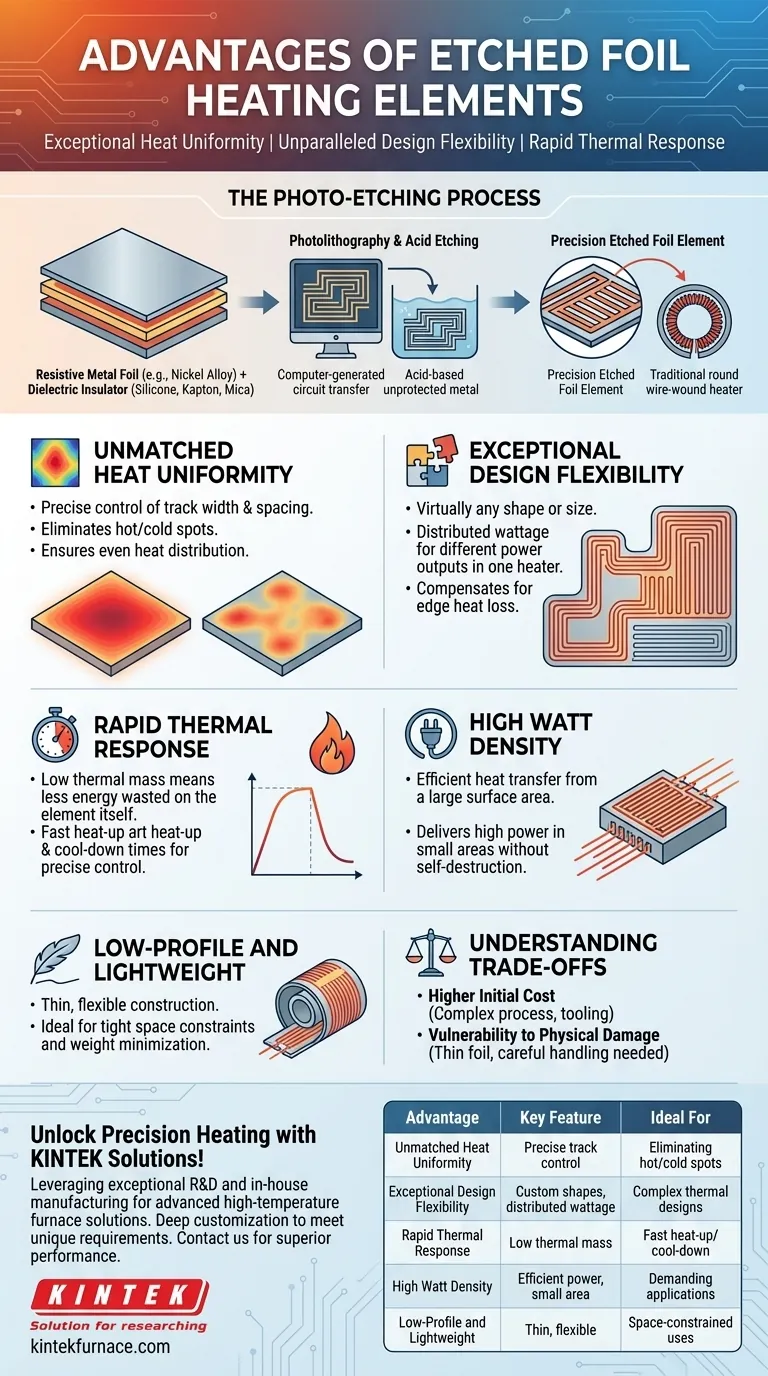

At their core, the primary advantages of etched foil heating elements are exceptional heat uniformity, unparalleled design flexibility, and a rapid thermal response. These benefits stem directly from their unique manufacturing process, which allows for the creation of intricate, computer-designed resistance patterns on a thin, flexible substrate.

While simpler heating technologies exist, etched foil is the definitive choice for applications where precise, uniform, and complex heat distribution is a critical design requirement. It trades higher initial cost for superior thermal performance and control.

How Etched Foil Achieves Superior Performance

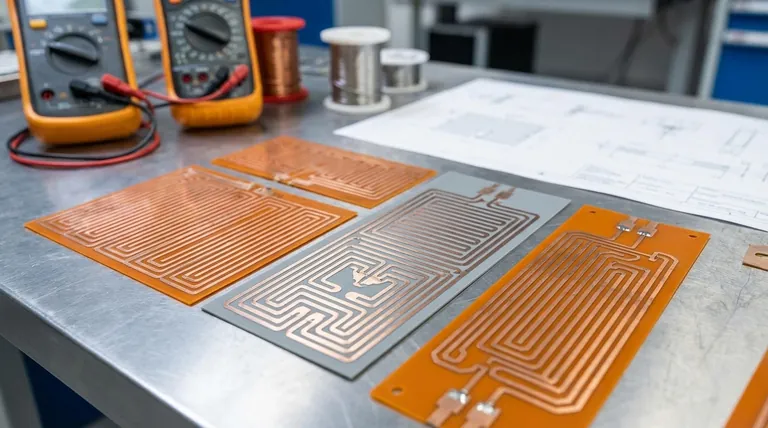

To understand the advantages of etched foil, you must first understand how it is made. Unlike traditional wire-wound heaters, etched foil elements are produced with a level of precision akin to manufacturing a printed circuit board.

The Photo-Etching Process

The process begins with a thin sheet of resistive metal foil, such as a nickel-based alloy, which is laminated to a dielectric insulating material like silicone, Kapton®, or mica.

A computer-generated circuit pattern is transferred to the foil using photolithography. An acid-based solution then etches away the unprotected metal, leaving behind a precise, planned-out resistive track. This subtractive process is what enables incredibly complex and repeatable heating patterns.

The Resulting Construction

The final product is a thin, low-profile heater with a large, flat heating element. This element has a significantly higher percentage of its surface area in direct contact with the heated part compared to the round wires in a wire-wound heater, which is the physical basis for its performance benefits.

The Core Advantages Explained

The manufacturing method directly translates into tangible performance benefits that are difficult or impossible to achieve with other technologies.

Unmatched Heat Uniformity

Because the resistive track is chemically etched, its width and spacing can be controlled with extreme precision. This allows designers to distribute wattage exactly where it is needed, eliminating the hot and cold spots common with wire-wound elements and ensuring exceptionally uniform heat across a surface.

Exceptional Design Flexibility

The photo-etching process is not limited to simple patterns. Heaters can be designed in virtually any shape or size. More importantly, this allows for distributed wattage, where different areas of a single heater can have different power outputs. This is ideal for compensating for predictable heat loss at the edges of a component.

Rapid Thermal Response

Etched foil heaters have very little mass relative to their surface area. This low thermal mass means less energy is wasted heating the element itself, allowing for much faster heat-up and cool-down times. This makes them ideal for applications requiring tight temperature cycling and precise control.

High Watt Density

The large surface area of the foil track allows for a more efficient transfer of heat into the target component. This enables etched foil heaters to deliver a high amount of power in a very small area (high watt density) without self-destructing, a critical feature for demanding aerospace and medical applications.

Low-Profile and Lightweight

The final heater assembly is exceptionally thin and lightweight. This makes it the perfect solution for applications with tight space constraints or where minimizing weight is a primary design goal.

Understanding the Trade-offs

No technology is without its limitations. Being objective requires understanding where etched foil may not be the optimal choice.

Higher Initial Cost

The multi-step photolithography process and the cost of tooling for custom designs make etched foil heaters more expensive than simpler wire-wound or cartridge heaters. The cost difference is most pronounced in low-volume or simple, non-critical applications.

Vulnerability to Physical Damage

While durable when properly installed, the thin foil element is more susceptible to damage from creasing, folding, or punctures than a robust metal-sheathed wire element. Careful handling and installation are critical to ensure long-term reliability.

Making the Right Choice for Your Application

Selecting the correct heating technology depends entirely on your project's specific engineering and budget priorities.

- If your primary focus is precision thermal control and uniformity for a complex part: Etched foil is the superior technology, especially for medical, analytical, or semiconductor equipment.

- If your primary focus is rapid temperature cycling: The low thermal mass of an etched foil heater provides a clear advantage over heavier wire-wound or ceramic options.

- If your primary focus is low-cost heating for a simple, non-critical application: A traditional wire-wound or flexible silicone rubber heater will likely be a more cost-effective solution.

Ultimately, choosing an etched foil heater is a decision to prioritize performance and design flexibility for demanding thermal challenges.

Summary Table:

| Advantage | Key Feature | Ideal For |

|---|---|---|

| Unmatched Heat Uniformity | Precise resistive track control | Eliminating hot/cold spots |

| Exceptional Design Flexibility | Custom shapes and distributed wattage | Complex thermal designs |

| Rapid Thermal Response | Low thermal mass | Fast heat-up and cool-down cycles |

| High Watt Density | Efficient power in small areas | Demanding aerospace and medical uses |

| Low-Profile and Lightweight | Thin, flexible construction | Space-constrained applications |

Unlock Precision Heating with KINTEK Solutions!

Are you facing challenges with heat uniformity, rapid cycling, or complex thermal designs in your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements.

Let us help you achieve superior performance and efficiency—contact us today to discuss how our etched foil heating elements and other innovations can elevate your applications!

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the temperature range where MoSi2 heating elements should not be used for long periods? Avoid 400-700°C to Prevent Failure

- What are the advantages of using molybdenum-disilicide heating elements for aluminum alloy processing? (Rapid Heating Guide)

- What ceramic materials are commonly used for heating elements? Discover the Best for Your High-Temp Needs

- What are the primary applications of MoSi2 heating elements in research? Achieve Reliable High-Temp Control for Material Synthesis

- What are the key differences between SiC and MoSi2 heating elements in sintering furnaces? Choose the Right Element for Your High-Temp Needs