From a clinical and operational standpoint, chairside sintering fundamentally transforms a dental practice's restorative workflow. It enables the in-house fabrication of high-strength zirconia restorations within a single patient appointment, drastically improving practice efficiency, enhancing patient satisfaction, and giving clinicians complete control over the final outcome.

The true advantage of chairside sintering is not merely speed, but the strategic shift it represents. By bringing the entire restorative process in-house, practices capture value previously outsourced to labs and gain direct control over quality and the patient experience.

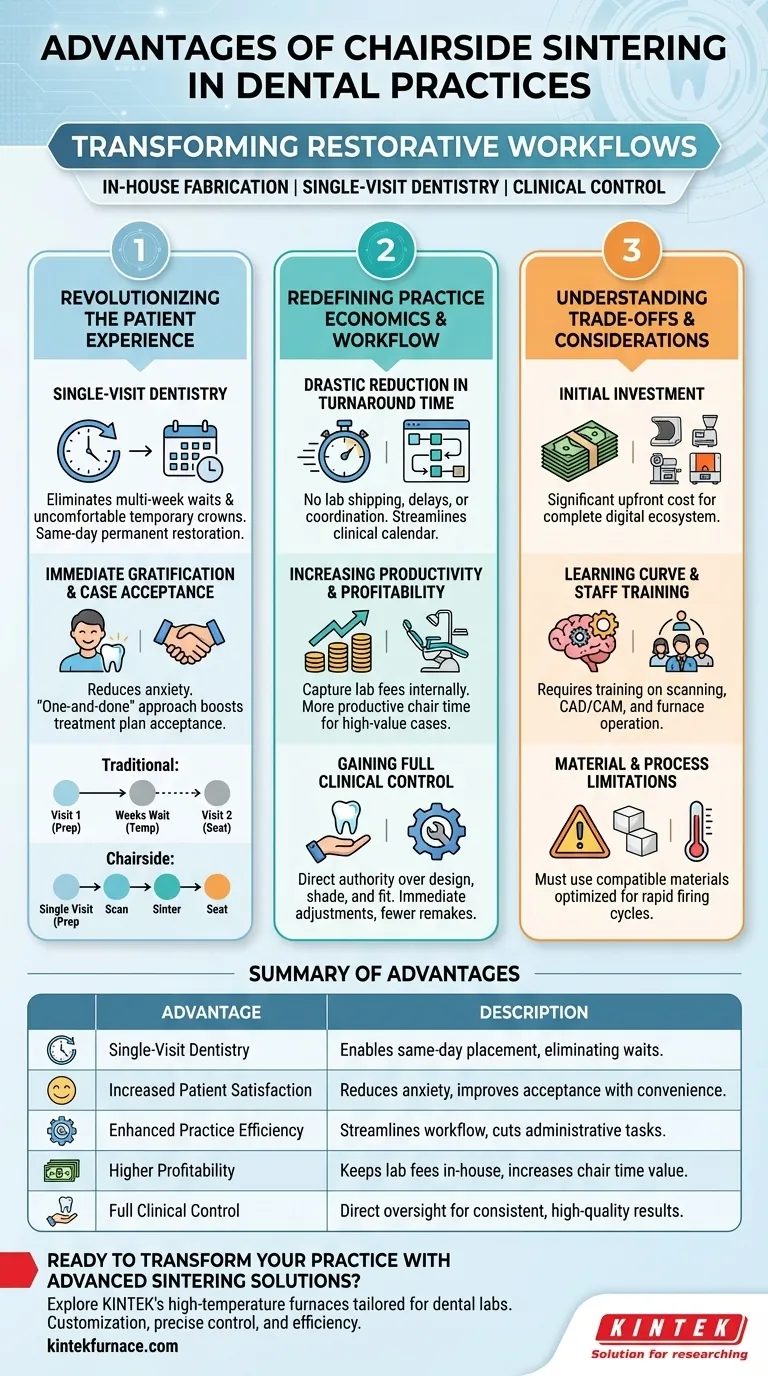

Revolutionizing the Patient Experience

The most immediate and marketable benefit of chairside sintering is its impact on the patient. Moving from a multi-week process to a single-visit solution is a significant differentiator.

The Power of Single-Visit Dentistry

Traditionally, a crown requires at least two visits: one for preparation and impression, and a second for seating the final restoration weeks later. In between, the patient must wear a temporary crown, which can be uncomfortable or aesthetically displeasing.

Chairside sintering eliminates this entire waiting period. The patient can have their tooth prepared, scanned, and restored with a permanent, full-strength zirconia crown in one sitting, offering unparalleled convenience.

Immediate Gratification and Case Acceptance

This "one-and-done" approach significantly reduces patient anxiety and time away from their work or life. When a patient understands they can walk out with a final, durable restoration on the same day, their willingness to accept the proposed treatment plan often increases dramatically.

Redefining Practice Economics and Workflow

Beyond patient benefits, chairside sintering offers profound operational and financial advantages by internalizing a key production step.

Drastic Reduction in Turnaround Time

The logistical complexity of coordinating with an external dental lab disappears. There are no more shipping delays, communication errors, or scheduling conflicts for a second appointment. This frees up administrative time and streamlines the entire clinical calendar.

Increasing Productivity and Profitability

By completing a crown case in a single, extended appointment rather than two separate ones, chair time becomes more productive. The fees that would have been paid to an external lab are instead kept within the practice, directly boosting the profitability of each restorative procedure. This efficiency allows for more high-value cases to be completed.

Gaining Full Clinical Control

Relying on an external lab means relinquishing control over the final product. Chairside sintering gives the clinician direct authority over every step, from the digital design to the final shade and fit.

This precise control over the sintering process ensures consistent, high-quality results. If minor adjustments to fit or color are needed, they can be made immediately, eliminating the costly and time-consuming process of sending a case back to the lab for a remake.

Understanding the Trade-offs and Considerations

While powerful, adopting chairside sintering requires a holistic view of the necessary changes to a practice's infrastructure and workflow.

The Initial Investment

A chairside sintering furnace is part of a larger digital ecosystem. A practice must also have an intraoral scanner and a milling machine. The combined upfront capital investment for this equipment is significant.

The Learning Curve and Staff Training

This technology is not "plug and play." The dental team must be trained on the complete digital workflow, including scanning protocols, CAD/CAM design principles, and furnace operation. A commitment to training is essential for achieving predictable and high-quality results.

Material and Process Limitations

Fast sintering cycles are optimized for specific types of zirconia blocks. Clinicians must ensure they are using compatible materials designed for rapid firing to avoid compromising the material's strength or aesthetic properties.

Making the Right Choice for Your Practice

Integrating chairside sintering is a strategic decision that should align with your practice's core goals.

- If your primary focus is patient growth and satisfaction: The single-visit appointment is a powerful marketing tool that provides a level of convenience few competitors can offer.

- If your primary focus is increasing profitability: This technology allows you to capture the full revenue from restorative cases by eliminating external lab fees and increasing daily production capacity.

- If your primary focus is clinical control and quality: In-house sintering offers unparalleled command over the final restoration, dramatically reducing remakes and ensuring predictable outcomes.

Ultimately, adopting chairside sintering empowers you to take complete ownership of your restorative workflow, from impression to final placement.

Summary Table:

| Advantage | Description |

|---|---|

| Single-Visit Dentistry | Enables same-day crown placement, eliminating multi-week waits and temporary restorations. |

| Increased Patient Satisfaction | Reduces anxiety and improves case acceptance with immediate, convenient treatment. |

| Enhanced Practice Efficiency | Streamlines workflow by cutting lab coordination and administrative tasks. |

| Higher Profitability | Keeps lab fees in-house and allows more productive use of chair time. |

| Full Clinical Control | Provides direct oversight of design, sintering, and fit for consistent, high-quality results. |

Ready to transform your dental practice with advanced sintering solutions? Contact KINTEK today to explore our high-temperature furnaces, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, tailored for dental labs. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique needs, ensuring precise control and efficiency in your restorative workflows.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision