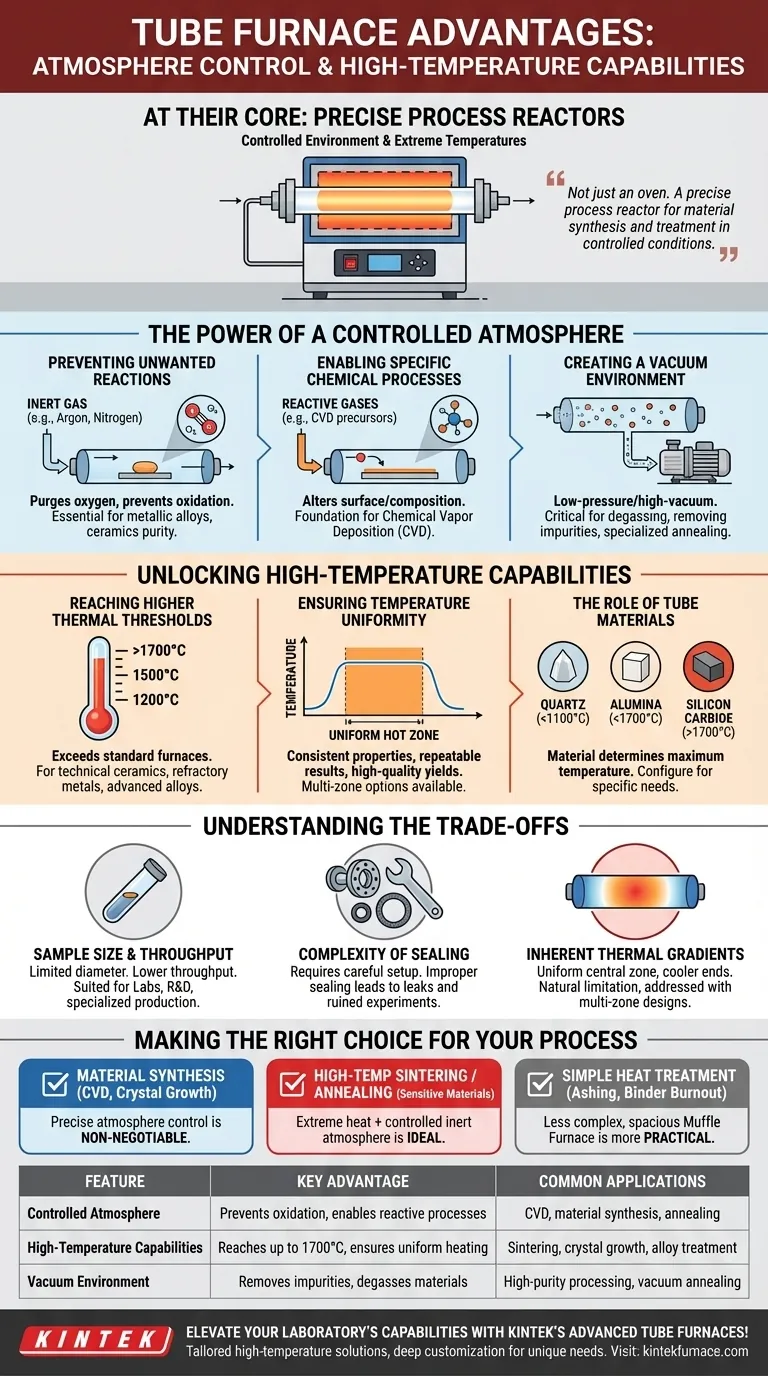

At their core, the primary advantages of a tube furnace are its capabilities for precise atmosphere control and achieving high temperatures. Unlike a simpler muffle furnace that heats samples in ambient air, a tube furnace’s sealed chamber allows you to create highly specific, controlled environments, making it indispensable for advanced processes like annealing, sintering, and chemical vapor deposition (CVD).

A tube furnace should not be viewed as just an oven. It is a precise process reactor. Its ability to manipulate the internal atmosphere and reach extreme temperatures enables the synthesis and treatment of materials that would be impossible to achieve in an open-air environment.

The Power of a Controlled Atmosphere

The single most defining feature of a tube furnace is its sealed tube, which isolates the sample from the outside air. This allows you to dictate the exact chemical environment, moving beyond simple heating to active material processing.

Preventing Unwanted Reactions

Many advanced materials are highly sensitive to oxygen, especially at high temperatures. Introducing an inert gas, like argon or nitrogen, purges the oxygen and creates a protective environment.

This prevents oxidation and other unwanted chemical reactions, ensuring the purity and integrity of materials like metallic alloys or certain ceramics during heat treatment.

Enabling Specific Chemical Processes

A tube furnace allows you to introduce reactive gases to intentionally alter a material's surface or composition. This is the foundation of powerful techniques like Chemical Vapor Deposition (CVD).

In CVD, precursor gases react at high temperatures to deposit a thin film onto a substrate. This process is impossible without the precise atmospheric control offered by a tube furnace.

Creating a Vacuum Environment

By connecting a vacuum pump, a tube furnace can be evacuated to create low-pressure or high-vacuum conditions.

This is critical for processes like degassing materials to remove trapped impurities or for certain types of annealing where even trace amounts of gas could interfere with the desired outcome.

Unlocking High-Temperature Capabilities

While atmosphere control is one pillar, the ability to reach and maintain extreme temperatures is the other. This capability is dictated by the furnace's heating elements and the material of the process tube itself.

Reaching Higher Thermal Thresholds

Tube furnaces are designed to achieve temperatures that often exceed those of standard muffle or chamber furnaces, with some models reaching 1200°C, 1500°C, or even higher.

This high-temperature performance is essential for processing materials with very high melting or sintering points, such as technical ceramics, refractory metals, and advanced alloys.

Ensuring Temperature Uniformity

A key design feature of a tube furnace is its ability to create a highly uniform hot zone in the center of the tube. This ensures that the entire sample experiences the same thermal conditions.

This uniformity is critical for achieving consistent material properties, repeatable experimental results, and high-quality production yields. Multi-zone furnaces offer even greater control over the temperature profile along the tube's length.

The Role of Tube Materials

The maximum achievable temperature is directly linked to the process tube material. This versatility allows you to configure the furnace for your specific needs.

Quartz tubes are common for processes up to around 1100°C. For higher temperatures, more robust ceramic tubes made of alumina (up to 1700°C) or even silicon carbide (SiC) are required.

Understanding the Trade-offs

While powerful, tube furnaces have inherent limitations that are important to understand. Their design prioritizes environmental control, which comes with certain practical trade-offs.

Sample Size and Throughput

The diameter of the process tube naturally limits the physical size of the samples you can process.

Compared to a bulkier chamber or muffle furnace, the throughput of a tube furnace is generally lower, making it better suited for labs, R&D, and specialized production rather than mass processing of large components.

Complexity of Sealing

Achieving a truly gas-tight or vacuum-sealed environment requires careful setup. This involves using specialized flanges, gaskets, and fittings.

Improper sealing can lead to leaks, compromising the atmospheric integrity and ruining an experiment. This adds a layer of operational complexity compared to a simple "open and close" chamber furnace.

Inherent Thermal Gradients

While the central hot zone is uniform, the ends of the tube will always be cooler. This thermal gradient is a natural characteristic of the design.

While this can be used avantajously for creating specific process conditions, it is a limitation if a very long, uniform hot zone is required. This challenge is typically addressed with more complex and expensive multi-zone furnace designs.

Making the Right Choice for Your Process

Your choice of furnace should be dictated entirely by the requirements of your application.

- If your primary focus is material synthesis (like CVD or crystal growth): The precise atmosphere control of a tube furnace is non-negotiable and essential for your work.

- If your primary focus is high-temperature sintering or annealing of sensitive materials: The combination of extreme heat and a controlled inert atmosphere makes a tube furnace the ideal choice.

- If your primary focus is simple heat treatment in air (like ashing or binder burnout): A less complex and more spacious muffle furnace is likely a more practical and cost-effective solution.

Ultimately, the tube furnace is an indispensable and versatile tool for precise control over the fundamental variables of material engineering.

Summary Table:

| Feature | Key Advantage | Common Applications |

|---|---|---|

| Controlled Atmosphere | Prevents oxidation, enables reactive processes | CVD, material synthesis, annealing |

| High-Temperature Capabilities | Reaches up to 1700°C, ensures uniform heating | Sintering, crystal growth, alloy treatment |

| Vacuum Environment | Removes impurities, degasses materials | High-purity processing, vacuum annealing |

Elevate your laboratory's capabilities with KINTEK's advanced tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored high-temperature solutions, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization ensures precise fit for your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your material processing goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision