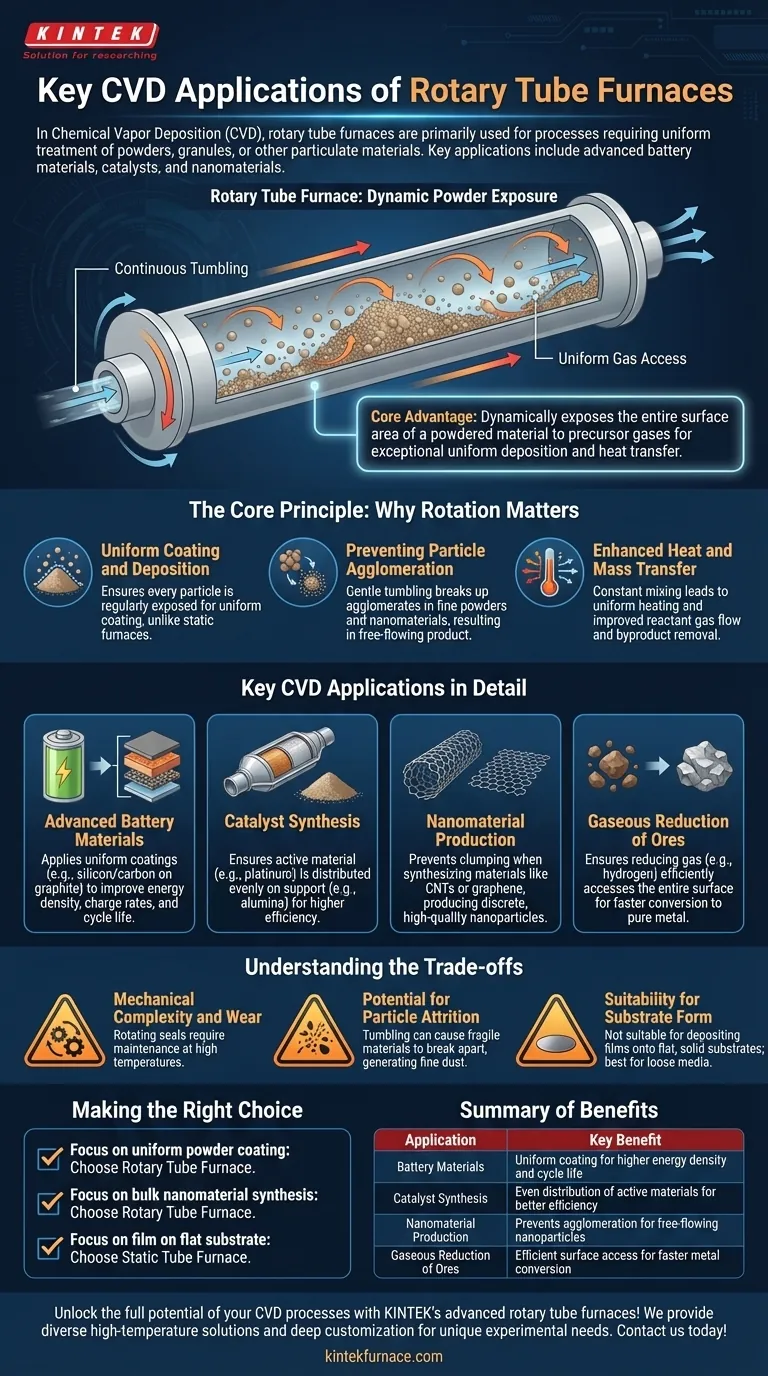

In Chemical Vapor Deposition (CVD), rotary tube furnaces are primarily used for processes requiring uniform treatment of powders, granules, or other particulate materials. Key applications include the synthesis of advanced battery materials, the preparation of high-performance catalysts, and the production of nanomaterials like graphene and carbon nanotubes where consistent coating and the prevention of particle agglomeration are critical.

The core advantage of a rotary tube furnace in CVD is its ability to dynamically and continuously expose the entire surface area of a powdered material to precursor gases. This ensures exceptionally uniform deposition and heat transfer, a feat that is nearly impossible to achieve with a static powder bed.

The Core Principle: Why Rotation Matters in CVD

The defining feature of this furnace is its rotating process tube. This simple mechanical action fundamentally changes the environment for CVD on particulate materials compared to a standard, stationary furnace.

Uniform Coating and Deposition

In a static furnace, precursor gases primarily react with the top layer of a powder. A rotary furnace solves this by continuously tumbling the material, ensuring every particle is regularly exposed at the surface for a uniform coating.

Preventing Particle Agglomeration

Fine powders, especially nanomaterials, have a strong tendency to clump together due to van der Waals forces. The gentle tumbling action of a rotary furnace continuously breaks up these agglomerates, resulting in a free-flowing, high-quality final product.

Enhanced Heat and Mass Transfer

The constant mixing of the material ensures much more uniform heating than in a static pile, where the outside can be much hotter than the core. This movement also improves the flow of reactant gases to the particle surface and the removal of byproducts, leading to a more efficient reaction.

Key CVD Applications in Detail

The unique advantages of rotation make these furnaces indispensable for specific, high-value CVD applications involving powders.

Advanced Battery Materials

The performance of lithium-ion batteries depends heavily on the quality of their anode and cathode materials. Rotary furnaces are used to apply uniform coatings—such as silicon or carbon on graphite particles—via CVD. This uniformity is essential for improving energy density, charge/discharge rates, and cycle life.

Catalyst Synthesis

Many industrial catalysts consist of an active material (like platinum) deposited onto a high-surface-area powder support (like alumina). Using a rotary furnace for CVD ensures the active material is distributed evenly across the support, maximizing the catalytic surface area and leading to higher efficiency and selectivity.

Nanomaterial Production

When synthesizing materials like carbon nanotubes (CNTs) or graphene on powdered substrates, preventing the product from clumping is a primary challenge. The anti-agglomeration effect of a rotary furnace is critical for producing discrete, high-quality nanoparticles at a larger scale.

Gaseous Reduction of Ores

While a broader thermal process, the gaseous reduction of powdered metal ores is a surface reaction closely related to CVD. A rotary furnace ensures the reducing gas (e.g., hydrogen) can efficiently access the entire surface of the ore particles, accelerating the conversion to pure metal.

Understanding the Trade-offs

While powerful, rotary tube furnaces are not a universal solution. Understanding their limitations is key to making an informed decision.

Mechanical Complexity and Wear

The rotating seals at the ends of the process tube are complex components that must maintain an airtight seal at high temperatures. These seals are subject to wear and require more maintenance than the simple flanges on a static furnace.

Potential for Particle Attrition

For very fragile or brittle materials, the tumbling action, however gentle, can cause particles to break apart. This phenomenon, known as attrition, can generate fine dust that may be undesirable or create handling issues.

Suitability for Substrate Form

These furnaces are specifically designed for powders, granules, and other loose media. They are entirely unsuitable for depositing films onto flat, solid substrates like silicon wafers or glass plates, where a static furnace is the correct tool.

Making the Right Choice for Your Process

Selecting the right furnace depends entirely on the physical form of the material you are processing.

- If your primary focus is uniform powder coating: A rotary tube furnace is the superior choice for applications like battery materials and catalysts.

- If your primary focus is bulk nanomaterial synthesis: The anti-agglomeration benefit makes a rotary furnace essential for producing high-quality, free-flowing nanopowders.

- If your primary focus is depositing a film on a flat, solid substrate: A conventional static tube furnace is the correct, more straightforward, and cost-effective tool for the job.

Ultimately, your choice is dictated by whether your material needs to be held still or kept in constant, controlled motion.

Summary Table:

| Application | Key Benefit |

|---|---|

| Battery Materials | Uniform coating for higher energy density and cycle life |

| Catalyst Synthesis | Even distribution of active materials for better efficiency |

| Nanomaterial Production | Prevents agglomeration for free-flowing nanoparticles |

| Gaseous Reduction of Ores | Efficient surface access for faster metal conversion |

Unlock the full potential of your CVD processes with KINTEK's advanced rotary tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether you're synthesizing battery materials, catalysts, or nanomaterials. Contact us today to discuss how our expertise can enhance your lab's performance and drive innovation!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing