In essence, high vacuum furnaces are used for mission-critical thermal processes where material purity and structural integrity cannot be compromised. They are indispensable for joining, treating, and forming advanced materials in industries like aerospace, medical, and electronics by creating an environment free from atmospheric contamination. This allows for processes like brazing, sintering, and heat treatment to be performed with unmatched precision.

The core purpose of a high vacuum furnace is not merely to heat materials, but to create a chemically inert environment. By removing reactive gases like oxygen and nitrogen, these furnaces prevent unwanted oxidation and contamination, enabling the creation of components with superior strength, purity, and specific properties unattainable in a conventional atmosphere.

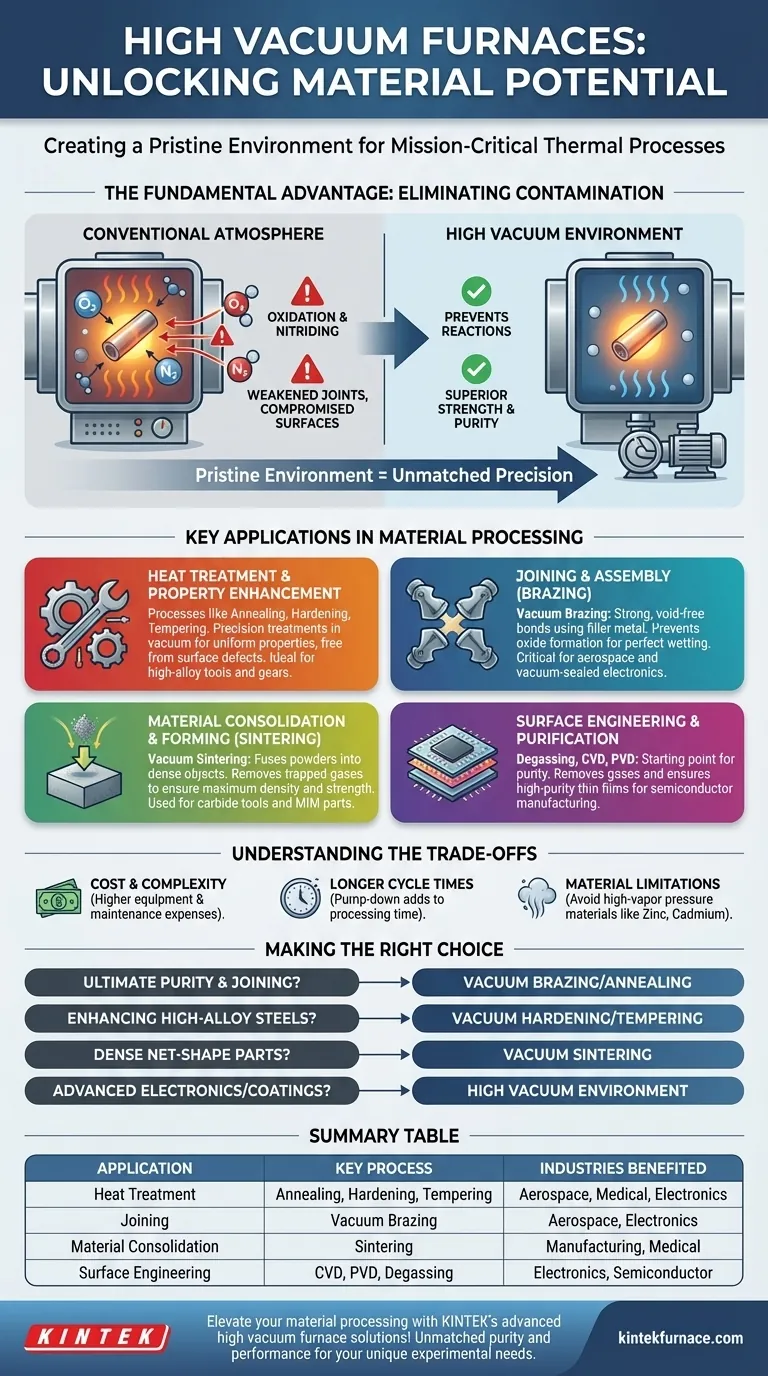

The Fundamental Advantage: Eliminating Atmospheric Contamination

At the high temperatures required for heat treatment, brazing, or sintering, most metals become highly reactive. Exposure to a normal atmosphere, which is primarily nitrogen and oxygen, can cause detrimental chemical reactions.

Preventing Oxidation and Nitriding

A high vacuum environment is one where the vast majority of air and other gas molecules have been pumped out. By removing oxygen, the furnace prevents the formation of oxide layers that can weaken joints, compromise surface finish, and alter a material's electrical or mechanical properties.

Similarly, removing nitrogen is critical when processing certain metals, like titanium, which can form brittle nitrides at elevated temperatures.

The Power of a Pristine Environment

This controlled environment is the key to unlocking the full potential of advanced materials. It is the difference between creating a standard component and one capable of performing under extreme conditions, such as inside a jet engine or a human body.

Key Applications in Material Processing

The ability to control a material's environment at high temperatures enables several critical manufacturing processes. Each one leverages the vacuum to achieve a specific, high-purity outcome.

Heat Treatment and Property Enhancement

Processes like annealing (softening), hardening (quenching), and tempering alter a material's microstructure to achieve desired properties like hardness or ductility.

In a vacuum, these treatments are performed with absolute precision. The final material is free from surface decarburization or oxidation, ensuring its properties are uniform from the surface to the core. This is essential for components like high-alloy steel tools and gears.

Joining and Assembly (Brazing)

Vacuum brazing is a superior method for joining complex parts. A filler metal with a lower melting point is used to bond two components together.

The vacuum ensures the filler metal flows cleanly into the joint, creating a strong, void-free bond. Without a vacuum, oxides would form on the component surfaces, preventing proper wetting by the filler metal and resulting in a weak or failed joint. This is critical for aerospace components and vacuum-sealed electronic devices.

Material Consolidation and Forming (Sintering)

Sintering is the process of taking metal or ceramic powders and fusing them into a solid, dense object under heat and pressure.

Performing this in a vacuum is vital for removing trapped gases between the powder particles. This prevents porosity and ensures the final part achieves maximum density and strength. This technique is used for making everything from carbide cutting tools to complex parts via Metal Injection Molding (MIM).

Surface Engineering and Purification

A high vacuum is the starting point for processes like degassing, Chemical Vapor Deposition (CVD), and Physical Vapor Deposition (PVD).

Degassing removes dissolved gases from within a material, a critical step for components used in ultra-high vacuum systems. For CVD and PVD, which deposit thin films onto a substrate, the vacuum environment is non-negotiable to ensure the purity and adhesion of the deposited layer, a cornerstone of semiconductor manufacturing.

Understanding the Trade-offs

While incredibly powerful, high vacuum technology is not a universal solution. It involves specific challenges and limitations that must be considered.

Cost and Complexity

High vacuum furnaces are significantly more expensive to purchase, operate, and maintain than their atmospheric counterparts. The vacuum pumps, control systems, and chamber seals require specialized knowledge and regular service.

Longer Cycle Times

The process of pumping a chamber down to a high vacuum level takes time. This "pump-down" phase adds to the total cycle time, making vacuum furnaces slower for high-volume, lower-spec applications.

Material Limitations

Not all materials are suitable for high vacuum processing. Materials with high vapor pressures (like zinc, cadmium, or magnesium) can vaporize, or "outgas," under vacuum at high temperatures. This can contaminate both the furnace and the workpiece itself.

Making the Right Choice for Your Goal

Selecting the correct thermal process depends entirely on the material requirements and the performance demands of the final application.

- If your primary focus is ultimate material purity and joining reactive metals: A high vacuum process like vacuum brazing or annealing is non-negotiable to prevent component-degrading reactions.

- If your primary focus is enhancing the mechanical properties of high-alloy steels: Vacuum hardening and tempering are essential to prevent surface defects and ensure uniform strength and hardness.

- If your primary focus is creating dense, net-shape parts from powders: Vacuum sintering is the definitive method for achieving full density and avoiding internal defects or trapped gas porosity.

- If your primary focus is producing advanced electronics or coatings: The ultra-clean environment of a high vacuum furnace is the only way to achieve the purity required for semiconductor crystal growth and thin-film deposition.

Ultimately, employing a high vacuum furnace is a strategic decision to control a material's chemistry at the atomic level, delivering performance and reliability that are simply impossible to achieve otherwise.

Summary Table:

| Application | Key Process | Industries Benefited |

|---|---|---|

| Heat Treatment | Annealing, Hardening, Tempering | Aerospace, Medical, Electronics |

| Joining | Vacuum Brazing | Aerospace, Electronics |

| Material Consolidation | Sintering | Manufacturing, Medical |

| Surface Engineering | CVD, PVD, Degassing | Electronics, Semiconductor |

Elevate your material processing with KINTEK's advanced high vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, delivering unmatched purity and performance in industries such as aerospace, medical, and electronics. Contact us today to discuss how we can enhance your thermal processes and achieve superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion