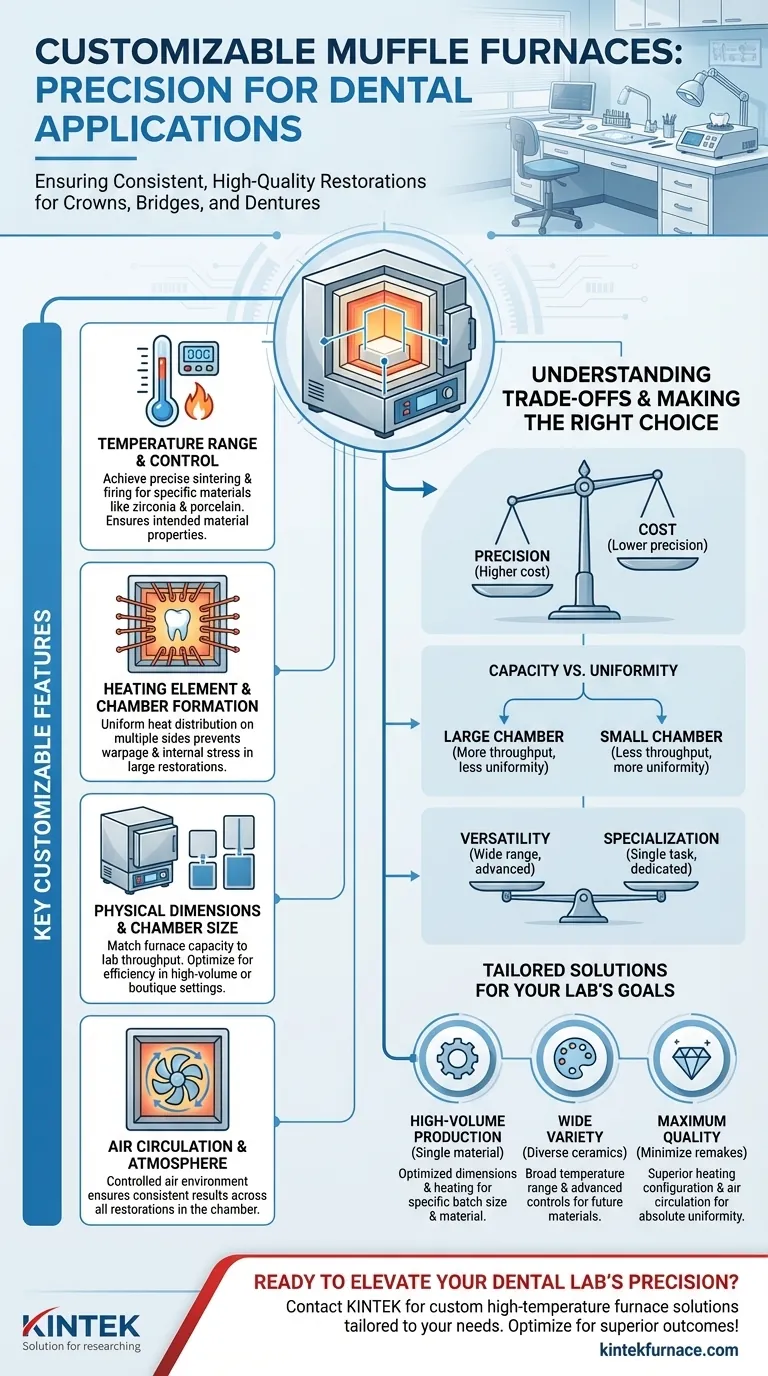

In a modern dental laboratory, the quality of a restoration is directly tied to the precision of the tools used. For processes like creating crowns, bridges, and dentures, the muffle furnace is a critical instrument. The ability to customize this furnace is not a luxury but a necessity for achieving optimal results, with the most common customizable features being temperature range, heating element configuration, physical dimensions, and air circulation systems.

Customizing a muffle furnace is about more than just fitting it into your lab's physical space. It is about precisely engineering the heating environment to match the exact chemical and physical requirements of the specific dental materials you work with, ensuring consistent, high-quality outcomes.

The Furnace's Role in Dental Restorations

A muffle furnace provides an isolated, high-temperature chamber for heat-treating materials. In dentistry, this process is essential for tasks like sintering zirconia or firing ceramics.

The goal is to apply heat in a highly controlled manner to achieve the material's target strength, translucency, and color stability. Any deviation can lead to a weak, discolored, or ill-fitting restoration, resulting in costly remakes and lost time.

Key Areas of Customization Explained

Understanding how each customizable feature impacts the final product is crucial for making an informed decision. These four areas are the primary levers for controlling quality.

Temperature Range and Control

Different dental materials, such as zirconia and various types of porcelain, have unique and highly specific temperature cycles they must undergo.

A customizable furnace allows you to specify a temperature range and control precision that perfectly match the materials you use most. This ensures you can accurately hit and hold critical temperatures, which is fundamental to achieving the material's intended properties.

Heating Element and Chamber Formation

The arrangement of the heating elements dictates how uniformly heat is distributed throughout the chamber. This is not a minor detail.

Customizing the heating element configuration—for example, having elements on three or four sides of the chamber—prevents hot and cold spots. This uniformity is critical for preventing warpage or internal stress, especially in larger restorations like multi-unit bridges.

Physical Dimensions and Chamber Size

While fitting the furnace in your lab is a consideration, the internal chamber dimensions are primarily about workflow and efficiency.

Specifying the chamber size allows you to match the furnace's capacity to your lab's throughput. A high-volume lab can optimize for larger batch sizes, while a smaller, boutique lab might prioritize a smaller chamber for maximum temperature uniformity on complex cases.

Air Circulation and Atmosphere

The environment inside the furnace is just as important as the temperature. Some processes require a standard air atmosphere, while others may need specific conditions to prevent oxidation.

Customizing the air circulation system ensures that every restoration in the chamber, from the front to the back, is exposed to the same temperature and atmosphere. This guarantees consistent results across an entire batch of crowns or bridges.

Understanding the Trade-offs

Specifying a custom furnace involves balancing competing priorities. There is no single "best" configuration; there is only the best configuration for your specific goals.

Precision vs. Cost

Higher-end temperature controllers and more complex heating element designs deliver superior precision and uniformity. However, this advanced engineering comes at a higher initial cost. You must weigh the price against the long-term cost of inconsistent results and remakes.

Capacity vs. Uniformity

A larger furnace chamber allows you to process more units at once, increasing throughput. However, maintaining perfect temperature uniformity becomes more difficult and expensive as the chamber volume increases. For the most demanding aesthetic cases, a smaller, dedicated furnace may provide more reliable outcomes.

Versatility vs. Specialization

A furnace with a very wide temperature range and advanced programming offers the versatility to handle new materials that may come to market. Conversely, a furnace designed for a single, specific task—like sintering zirconia—may be simpler, more reliable, and more cost-effective for that dedicated purpose.

Making the Right Choice for Your Laboratory

Your choice of customization should be driven by your laboratory's primary function and business goals.

- If your primary focus is high-volume production of a single material: Prioritize a furnace with dimensions optimized for your standard batch size and a heating profile fine-tuned for that specific material's requirements.

- If your primary focus is working with a wide variety of dental ceramics and materials: Choose a furnace with a broader temperature range and advanced programming controls to accommodate diverse and future material needs.

- If your primary focus is maximizing quality and minimizing remakes: Invest in superior heating element configurations and air circulation systems to ensure absolute temperature uniformity across every restoration.

By carefully specifying these features, you transform a furnace from a simple piece of equipment into a precision instrument fundamental to your laboratory's success.

Summary Table:

| Customizable Feature | Key Benefit for Dental Labs |

|---|---|

| Temperature Range and Control | Achieves precise sintering and firing for materials like zirconia and ceramics |

| Heating Element Configuration | Ensures uniform heating to prevent warpage in crowns and bridges |

| Physical Dimensions and Chamber Size | Optimizes workflow efficiency for batch sizes in high-volume or boutique labs |

| Air Circulation and Atmosphere | Maintains consistent results across all restorations in the chamber |

Ready to elevate your dental lab's precision? At KINTEK, we specialize in custom high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer advanced products like Muffle Furnaces, Tube Furnaces, and more, with deep customization capabilities to ensure your restorations meet the highest standards of strength, translucency, and color stability. Don't let inconsistent results hold you back—contact us today to discuss how we can optimize your furnace for superior outcomes in crowns, bridges, and dentures!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab