At its core, a rotary furnace is used for the high-volume thermal processing of bulk materials and small parts. The most common processes performed are calcination, oxidation, and melting, where the furnace's continuous rotation ensures every particle receives uniform heat exposure, leading to a highly consistent final product.

The defining advantage of a rotary furnace is not just the heat it provides, but the mechanical mixing it performs. This makes it the ideal choice for processes requiring absolute temperature uniformity across a large volume of granular materials or small, individual components.

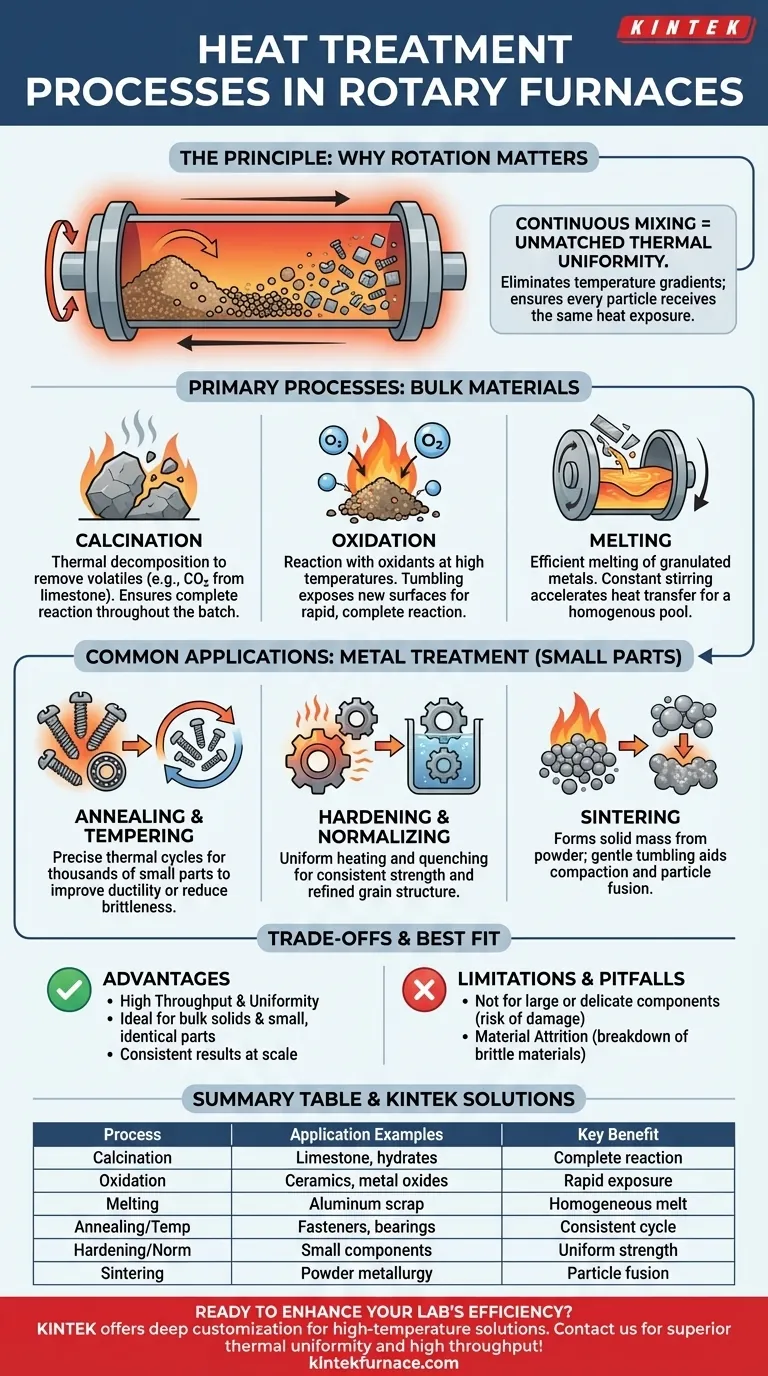

The Principle of Operation: Why Rotation Matters

The function of any furnace is to apply heat. However, the method of application defines its purpose. A rotary furnace, also known as a rotary kiln or retort furnace, is designed around one central principle: continuous agitation.

The Power of Continuous Mixing

The furnace chamber is a tube that rotates slowly along its horizontal axis. As it turns, the material inside—be it a fine powder, granules, or a batch of small parts—is constantly tumbled and mixed.

This tumbling action is critical. It ensures that no single part of the material batch is over- or under-heated, eliminating the temperature gradients that can plague static furnaces. Every particle is continuously cycled from the cooler center of the mass to the hot inner walls of the furnace.

Unmatched Thermal Uniformity

The result of this mixing is exceptional thermal uniformity. This is essential for chemical reactions and phase changes that are highly sensitive to temperature. Processes like calcination depend on every particle reaching a specific decomposition temperature to achieve complete conversion.

Primary Heat Treatment Processes

Rotary furnaces excel at transforming the fundamental properties of bulk materials. Their design is perfectly suited for processes where the entire volume of material must undergo a chemical or physical change.

Calcination

Calcination is a process of thermal decomposition, often used to remove a volatile component from a solid. The rotary furnace's uniform heating ensures the decomposition reaction runs to completion throughout the entire batch. Common examples include driving carbon dioxide from limestone to produce lime or removing crystalized water from hydrates.

Oxidation

Oxidation is a chemical reaction that increases a material's oxidation state, typically by reacting it with air or another gaseous oxidant at high temperatures. In a rotary furnace, the tumbling action constantly exposes new surfaces to the furnace atmosphere, facilitating a rapid and complete reaction. This is vital in industries like ceramics and the production of metal oxides.

Melting

For melting large quantities of material, particularly granulated metals like aluminum scrap, the rotary furnace is highly efficient. The constant stirring accelerates heat transfer into the bulk material, leading to faster melt times and a homogenous liquid metal pool.

Common Applications in Metal Treatment

While often associated with bulk chemical processing, rotary furnaces are also a mainstay in metallurgy for treating high volumes of small, individual parts where handling them one by one would be impractical.

Annealing and Tempering

Annealing (softening a metal to improve ductility) and tempering (reducing brittleness after hardening) require precise temperature control. A rotary furnace can process thousands of small parts, like fasteners, bearings, or stampings, in a single batch, ensuring each part receives the exact same thermal cycle.

Hardening and Normalizing

Similarly, processes like hardening (heating and quenching to increase strength) and normalizing (refining grain structure) can be applied to large batches of small components. The tumbling ensures uniform exposure to both the heat and, in some setups, the subsequent quenching medium.

Sintering

Sintering is the process of forming a solid mass of material by applying heat and pressure without melting it to the point of liquefaction. Rotary furnaces are used in powder metallurgy to sinter metal powders, where the gentle tumbling and uniform heat help compact and fuse the particles together.

Understanding the Trade-offs

No single technology is a universal solution. The strengths of a rotary furnace in one application become its limitations in another.

Advantage: High Throughput and Uniformity

The primary benefit is the ability to process large volumes of bulk solids or small parts with exceptional consistency. For powder, granular, or pelletized feedstock, no other furnace type offers this level of thermal uniformity at scale.

Limitation: Not for Large or Delicate Components

The tumbling action that makes a rotary furnace so effective for bulk materials makes it completely unsuitable for large, singular components or delicate parts that could be damaged by the mechanical agitation. A complex gear or a single large die would be processed in a static chamber or horizontal furnace.

Pitfall: Material Attrition

The constant tumbling can cause brittle materials to break down, creating fine dust and potentially altering the particle size distribution of the final product. This "attrition" must be considered when processing fragile granules or crystalline materials.

Making the Right Choice for Your Process

Selecting the correct furnace technology depends entirely on the form of your material and your processing goal.

- If your primary focus is bulk material transformation: For processes like calcination, oxidation, or roasting powders and granules, the rotary furnace is the undisputed industry standard.

- If your primary focus is high-volume parts treatment: For annealing, tempering, or hardening thousands of small, identical parts like screws or bearings, the rotary furnace provides unmatched efficiency and consistency.

- If your primary focus is processing large, single, or delicate parts: You must use a stationary furnace, such as a chamber or box furnace, to avoid mechanical damage and ensure precise control over a single workpiece.

Ultimately, choosing a rotary furnace is a decision to prioritize processing volume and thermal uniformity for materials that can withstand continuous mechanical mixing.

Summary Table:

| Process Type | Key Applications | Benefits |

|---|---|---|

| Calcination | Decomposition of limestone, hydrates | Uniform heating for complete reaction |

| Oxidation | Ceramics, metal oxides production | Rapid exposure to oxidants |

| Melting | Aluminum scrap, granulated metals | Faster heat transfer, homogeneous melt |

| Annealing/Tempering | Fasteners, bearings, stampings | Consistent thermal cycle for ductility |

| Hardening/Normalizing | Small components | Uniform strength and grain refinement |

| Sintering | Powder metallurgy | Particle fusion without liquefaction |

Ready to enhance your lab's efficiency with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced rotary furnaces and other systems like Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures we meet your unique experimental needs for bulk materials or small parts processing. Contact us today to discuss how our solutions can bring superior thermal uniformity and high throughput to your operations!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating