In material synthesis and industrial processing, a rotary furnace is a highly versatile tool for the thermal treatment of loose, granular, or powdered materials. Its most common applications include the calcination of minerals like alumina, the production of high-performance catalysts and pigments, and large-scale metallurgical processes such as smelting, roasting iron ore, and recovering lead from battery scrap. The furnace's unique design enables precise control over temperature and atmosphere to achieve specific material properties.

The core advantage of a rotary furnace is its ability to continuously tumble materials, ensuring every particle is uniformly exposed to heat and atmospheric conditions. This makes it the ideal choice for processes requiring high consistency and throughput for powders, grains, or pellets.

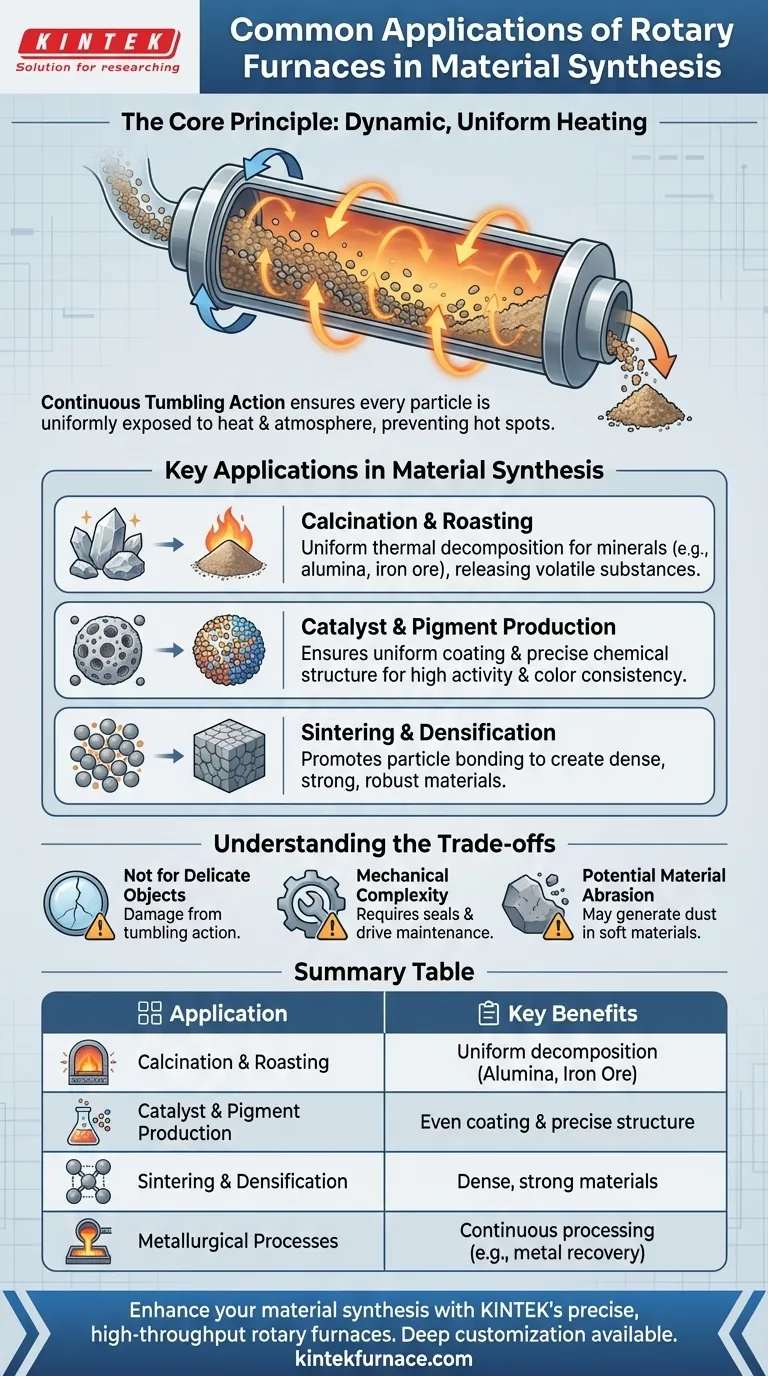

The Core Principle: Dynamic, Uniform Heating

The value of a rotary furnace stems from its fundamental design: a rotating cylindrical tube housed within a heating chamber. This simple mechanical action is the key to its effectiveness in specific applications.

How a Rotary Furnace Works

A rotary furnace, often called a rotary calciner or kiln, consists of a slightly inclined tube that rotates slowly. Raw material is fed into the higher end, and the combination of rotation and gravity causes it to tumble and move progressively toward the lower discharge end.

This continuous tumbling action is the furnace's defining feature. It constantly exposes new surfaces of the material to the furnace's controlled atmosphere and heat source.

The Benefit of Continuous Mixing

This constant mixing prevents the formation of hot spots and ensures that thermal or chemical reactions occur evenly throughout the entire batch of material. For processes where consistency is paramount, this uniformity is a significant advantage over static box furnaces, where material at the surface may react differently than material at the core.

Key Applications in Material Synthesis

The ability to process bulk solids uniformly makes the rotary furnace essential for synthesizing and refining materials where precise properties are required.

Calcination and Roasting

Calcination is a thermal decomposition process used to drive off volatile substances or induce a phase change. Roasting is a related gas-solid reaction, such as oxidation.

A rotary furnace is ideal for these tasks, with common examples including the calcination of alumina for ceramics, heating oil shale to release hydrocarbons, and roasting iron ore pellets to prepare them for smelting.

Catalyst and Pigment Production

Creating effective catalysts often requires depositing active metals onto a porous support material. The tumbling action ensures a uniform coating, leading to catalysts with high activity and selectivity.

Similarly, for pigments, consistent color and durability depend on achieving a precise chemical structure and particle size, which uniform heat treatment facilitates.

Sintering and Densification

Sintering is a process where heat is used to bond particles together, increasing a material's density and strength. The tumbling motion in a rotary furnace promotes contact between particles, aiding in the creation of dense, robust materials.

Understanding the Trade-offs

While powerful, a rotary furnace is not a universal solution. Understanding its limitations is critical for proper application.

Not Ideal for Static or Delicate Objects

The primary drawback is its unsuitability for processing single, large components or materials that could be damaged by the tumbling action. Forging large parts or heat-treating delicate optical lenses, for instance, requires a static furnace.

Mechanical Complexity and Maintenance

The rotating mechanism, including the drive system and high-temperature seals that maintain atmospheric integrity, adds mechanical complexity. These components require more maintenance than a simple static box furnace.

Potential for Material Abrasion

The continuous tumbling can cause abrasion, which may be undesirable for very friable or soft materials. This can lead to the generation of dust and a loss of product yield.

Making the Right Choice for Your Process

Selecting the correct furnace type depends entirely on the nature of your material and your process goals.

- If your primary focus is process consistency for bulk powders or pellets: A rotary furnace's tumbling action provides unparalleled thermal and chemical uniformity.

- If your primary focus is high-throughput continuous manufacturing: The design of a rotary furnace is inherently suited for continuous feeding and discharging, making it ideal for industrial-scale production.

- If you are processing single, large, or mechanically sensitive components: A static box or muffle furnace is the more appropriate choice to avoid damage from movement.

Ultimately, selecting a rotary furnace is a strategic decision to prioritize material uniformity and process efficiency for granular substances.

Summary Table:

| Application | Key Benefits |

|---|---|

| Calcination and Roasting | Uniform thermal decomposition for minerals like alumina and iron ore |

| Catalyst and Pigment Production | Ensures even coating and precise chemical structure for high activity |

| Sintering and Densification | Promotes particle bonding for dense, strong materials |

| Metallurgical Processes | Continuous processing for smelting and metal recovery, e.g., lead from batteries |

Ready to enhance your material synthesis with precise, high-throughput solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how our rotary furnaces can optimize your processes for superior consistency and efficiency!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- What are the key advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency for Your Materials

- What are some common applications of rotary tube furnaces? Unlock Efficient Bulk Material Processing

- How is heat transferred to the furnace tubes in a rotary tube furnace? Master Uniform Heating for Your Materials