In the biomedical field, Chemical Vapor Deposition (CVD) is a critical technology used to apply highly specialized, biocompatible coatings onto medical devices. These advanced films are used on everything from dental and joint implants to vascular stents and heart valves. The primary purpose is to improve the way these synthetic devices interact with human tissue, enhancing safety and extending their functional lifespan.

The core value of CVD in medicine is its ability to precisely engineer the surface of a device at the molecular level. This transforms a foreign object into a more integrated part of the biological system, fundamentally solving the challenges of biocompatibility, durability, and advanced functionality.

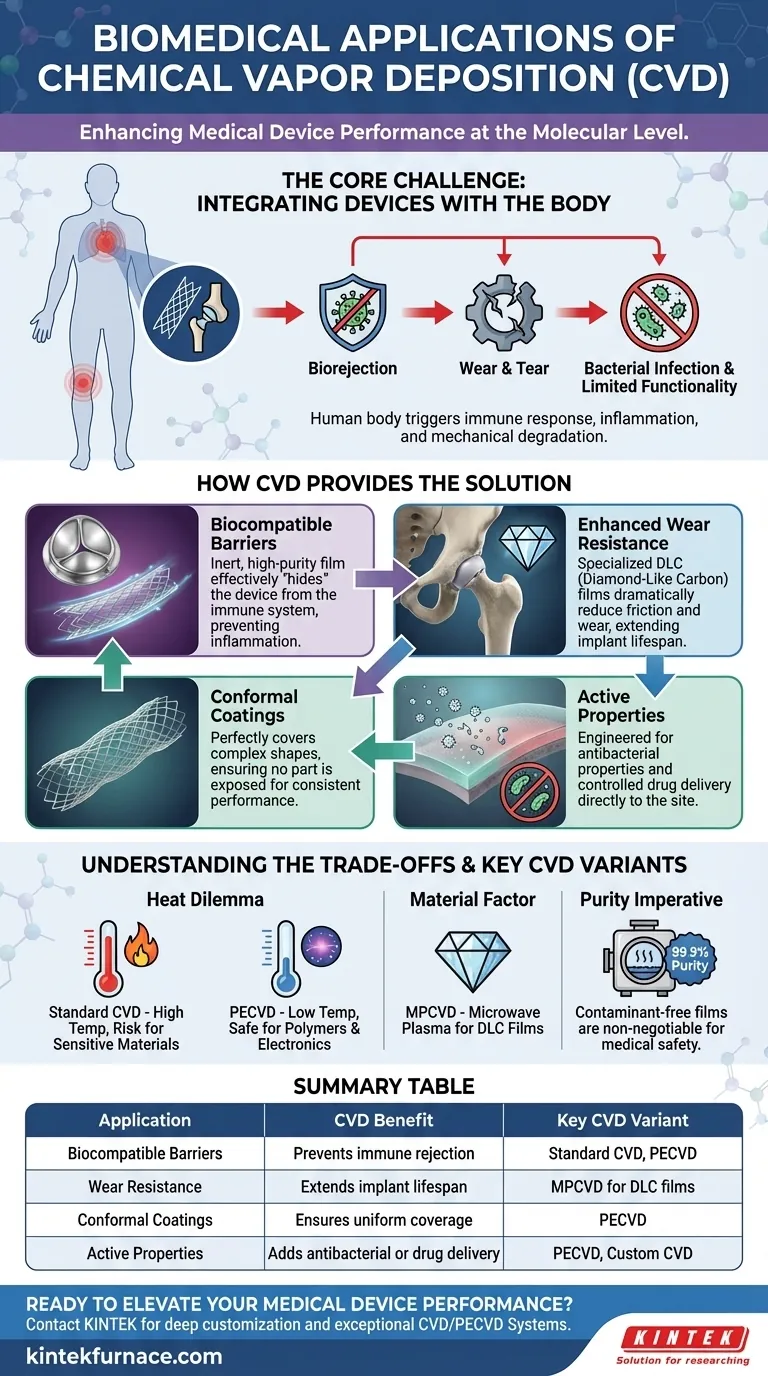

The Core Challenge: Integrating Devices with the Body

The human body is an incredibly complex and reactive environment. Introducing any synthetic device triggers a host of biological responses that can compromise its function and the patient's health.

The Problem of Biorejection

The immune system is designed to identify and attack foreign objects. An uncoated medical implant can trigger chronic inflammation or be encapsulated in scar tissue, leading to device failure and patient rejection.

The Need for Enhanced Durability

Implants, particularly artificial joints, are subjected to constant mechanical stress and friction. This wear and tear can degrade the implant over time, releasing potentially harmful particles into the body and necessitating difficult revision surgeries.

The Demand for Advanced Functionality

Modern medicine demands more than just passive implants. There is a growing need for devices with active properties, such as surfaces that can prevent bacterial infection or precisely release a therapeutic drug over time.

How CVD Provides the Solution

CVD addresses these challenges by fundamentally changing the surface properties of a medical device without altering its bulk material. It builds a new surface, one atom layer at a time.

Creating Biocompatible Barriers

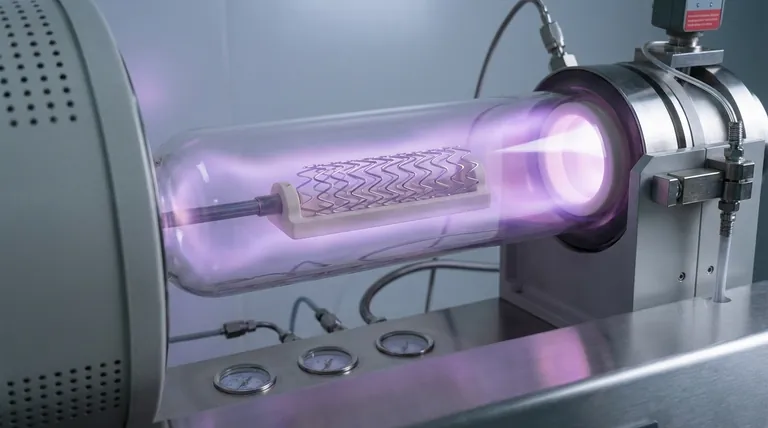

CVD is used to deposit a thin, dense, and exceptionally pure film that acts as a protective barrier. This coating effectively "hides" the underlying material (often a metal alloy) from the body's immune system.

These biocompatible coatings, applied to devices like vascular stents and heart valves, are inert and do not provoke an inflammatory response, dramatically reducing the risk of rejection.

Enhancing Wear Resistance with Specialized Films

For high-wear applications like artificial joints, a specific CVD process can be used to deposit diamond-like carbon (DLC) films. These surfaces are incredibly hard and have a very low coefficient of friction.

A DLC coating significantly reduces wear between the implant and surrounding bone or tissue, leading to better patient outcomes and a much longer implant lifespan.

Enabling Conformal and Uniform Coatings

One of CVD's key technical advantages is its ability to create conformal films. This means the coating perfectly and uniformly covers all surfaces of a complex shape, including the intricate mesh of a vascular stent.

This uniformity is critical for ensuring that no part of the underlying device is left exposed and that performance is consistent across the entire surface. This is also vital for the reliability of sensitive biosensors.

Adding Active Properties to a Surface

CVD can be used to create films with specific, active functions. For example, surfaces can be engineered to have inherent antibacterial properties, preventing dangerous infections from forming on implants.

Furthermore, it enables the creation of advanced drug delivery systems, where a coating is designed to release a specific medication at a controlled rate directly where it is needed.

Understanding the Trade-offs and Key CVD Variants

Not all CVD processes are the same. The specific technique is chosen based on the device's material and the desired outcome, highlighting the importance of understanding the available options.

The Heat Dilemma: Standard CVD vs. PECVD

Traditional CVD requires very high temperatures, which can damage heat-sensitive materials like polymers or the delicate electronics in a biosensor.

Plasma-Enhanced CVD (PECVD) is a low-temperature alternative. It uses a plasma to energize the precursor gases, allowing high-quality films to be deposited without exposing the device to damaging heat. This makes it essential for many modern biomedical applications.

The Material Factor: MPCVD for Diamond-Like Carbon

To create specialized films like DLC, an even more specific process is often required. Microwave Plasma CVD (MPCVD) is a preferred method for depositing these ultra-hard carbon films for orthopedic implants.

This demonstrates that the choice of CVD variant is directly tied to the specific material being deposited and the functional property required.

The Purity Imperative

In any medical application, purity is non-negotiable. Contaminants in a coating could be toxic or trigger an immune response. CVD processes, performed in a vacuum, excel at producing films of exceptionally high purity, making them a reliable choice for manufacturing medical-grade components.

Making the Right Choice for Your Goal

The application of CVD in your project depends entirely on the primary problem you need to solve.

- If your primary focus is biocompatibility: Use CVD to deposit an inert and high-purity barrier film to prevent immune rejection of implants like stents or heart valves.

- If your primary focus is implant longevity: Use specialized processes like MPCVD to apply hard, low-friction coatings such as diamond-like carbon on artificial joints.

- If your primary focus is coating sensitive materials: Use a low-temperature process like PECVD to protect polymers or electronic biosensors from heat damage during coating.

- If your primary focus is adding new capabilities: Design a CVD process to create a surface with active properties, such as preventing bacterial growth or enabling controlled drug release.

Ultimately, CVD gives engineers the power to control the crucial interface where technology meets biology, ensuring medical devices are safer, more durable, and more effective.

Summary Table:

| Application | CVD Benefit | Key CVD Variant |

|---|---|---|

| Biocompatible Barriers | Prevents immune rejection | Standard CVD, PECVD |

| Wear Resistance | Extends implant lifespan | MPCVD for DLC films |

| Conformal Coatings | Ensures uniform coverage on complex shapes | PECVD |

| Active Properties | Adds antibacterial or drug delivery functions | PECVD, Custom CVD |

Ready to elevate your medical device performance with advanced CVD solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions like Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for biomedical applications. Contact us today to discuss how we can enhance your device's biocompatibility, durability, and functionality!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the main differences between PVD and CVD coating techniques? Choose the Right Method for Your Application

- What are the key characteristics and advantages of CVD coatings? Enhance Durability and Precision for Complex Parts

- What types of coating precursors are used in the CVD deposition process? Essential Classes for Superior Film Quality

- What are some applications of chemical vapor deposition? Powering Electronics, Coatings, and Sensors

- In which industries is CVD particularly valuable? Unlock High-Performance Surface Engineering

- What types of heterostructures have been successfully synthesized using these CVD systems? Discover Advanced 2D Material Architectures

- What is a CVD machine? Build High-Performance Materials from Gas with Precision

- What does CVD stand for and what is its primary function? Discover High-Purity Thin Film Deposition