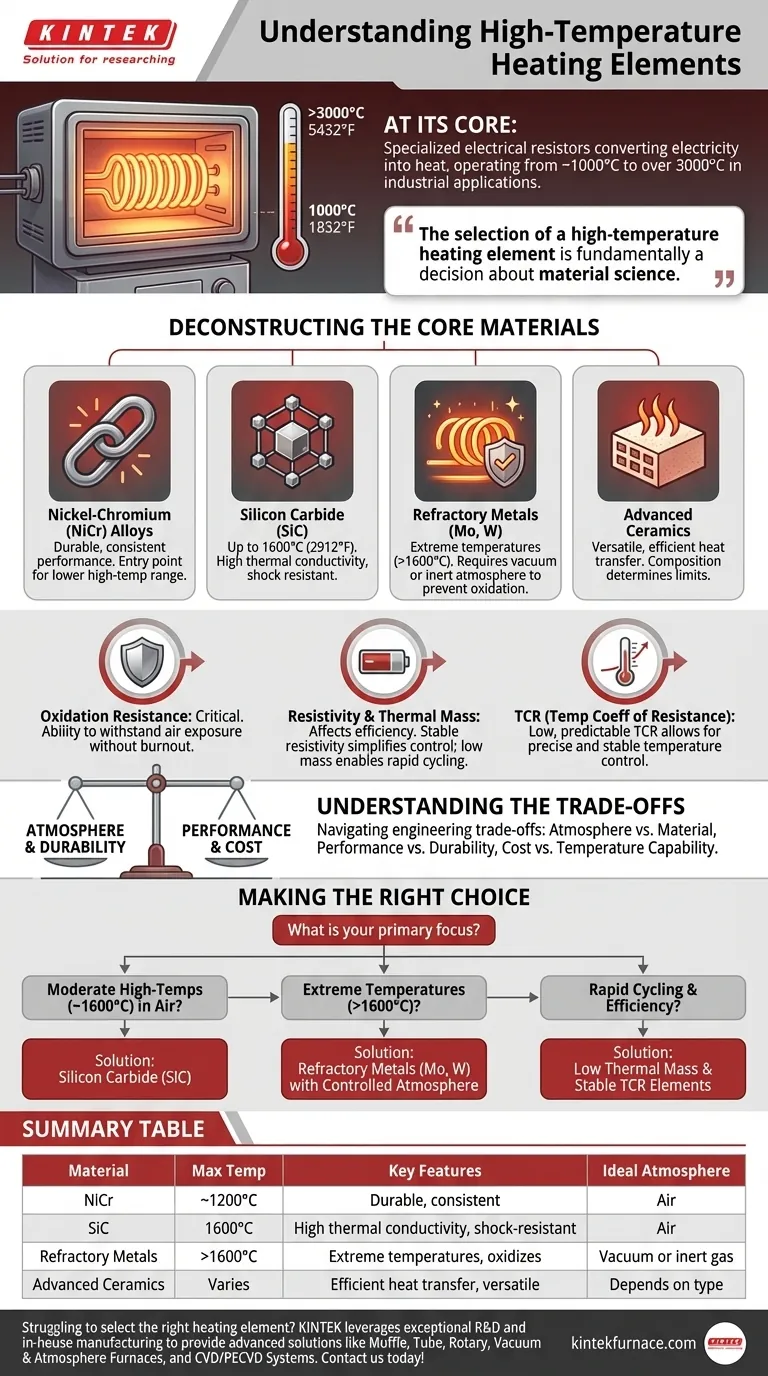

At its core, a high-temperature heating element is a specialized electrical resistor designed to convert electricity into heat and function reliably at extreme temperatures. These components are the workhorses of industrial heating, operating in a demanding range from approximately 1000°C (1832°F) to well over 3000°C (5432°F) in specialized applications like furnaces, ovens, and reactors.

The selection of a high-temperature heating element is fundamentally a decision about material science. The required operating temperature and surrounding atmosphere dictate which material—from common alloys to advanced ceramics—will deliver the necessary performance without rapid degradation.

Deconstructing the Core Materials

The material of a heating element is the single most important factor determining its performance, maximum temperature, and lifespan. Each class of material is suited for a different operational window.

Nickel-Chromium (NiCr) Alloys

Nickel-chromium alloys are often the entry point for industrial high-temperature applications. They are valued for their durability and consistent performance at the lower end of the high-temperature spectrum.

Silicon Carbide (SiC)

Silicon Carbide (SiC) elements are a significant step up, capable of operating at temperatures up to 1600°C (2912°F). They are known for their high thermal conductivity and excellent resistance to thermal shock, making them a popular choice for many industrial furnaces.

Refractory Metals (Molybdenum & Tungsten)

When applications demand temperatures beyond what SiC can handle, refractory metals like molybdenum and tungsten are required. These materials can reach exceptionally high temperatures but have a critical weakness: they oxidize and fail rapidly in the presence of air at those temperatures.

Advanced Ceramics

Ceramic heating elements represent a broad category known for highly efficient heat transfer and excellent thermal resistance. Their specific composition determines their temperature limits and suitability for various industrial processes, offering a versatile alternative to metallic elements.

Key Performance Characteristics

Beyond just the maximum temperature, several technical properties govern how an element will behave in a real-world application.

Oxidation Resistance

This is arguably the most critical factor after temperature rating. Oxidation resistance is the element's ability to withstand exposure to air without burning out. An element with poor oxidation resistance must be used in a vacuum or inert gas atmosphere.

Resistivity and Thermal Mass

Resistivity determines how effectively the material converts electricity into heat. A stable resistivity across different temperatures simplifies power control. Low thermal mass, a key advantage of some modern elements, allows for rapid heating and cooling cycles, improving process efficiency.

Temperature Coefficient of Resistance (TCR)

The TCR describes how much the element's electrical resistance changes as its temperature changes. A low and predictable TCR is highly desirable because it allows for precise and stable temperature control throughout the entire heating process.

Understanding the Trade-offs

Choosing an element is never about finding a single "best" option; it's about navigating a series of engineering trade-offs.

Atmosphere vs. Material

The most significant trade-off is between the required operating atmosphere and the material. An element like tungsten can achieve extreme temperatures, but this performance is only accessible if you can provide a vacuum or inert gas environment, adding complexity and cost to the system.

Performance vs. Durability

Some materials with exceptional thermal performance can be mechanically brittle or sensitive to chemical contamination. You must balance the need for rapid heating or high temperatures against the physical and chemical stresses of your specific industrial process.

Cost vs. Temperature Capability

There is a direct and steep correlation between cost and maximum operating temperature. While a NiCr alloy might be sufficient and cost-effective for 1100°C, reaching 1800°C or higher demands exotic and significantly more expensive materials like tungsten or specialized ceramics.

Making the Right Choice for Your Application

Your final decision must be guided by the specific goals and constraints of your heating process.

- If your primary focus is moderate high-temperatures (up to 1600°C) in air: Silicon Carbide (SiC) elements offer a robust and reliable solution.

- If your primary focus is extreme temperatures (above 1600°C): Refractory metals like molybdenum or tungsten are necessary, but you must plan for a controlled, non-oxidizing atmosphere.

- If your primary focus is rapid cycling and energy efficiency: Prioritize elements with low thermal mass and a stable temperature coefficient of resistance for precise control.

By matching the element's material properties to your specific thermal and atmospheric demands, you ensure reliable, efficient, and precise heating.

Summary Table:

| Material | Max Temperature | Key Features | Ideal Atmosphere |

|---|---|---|---|

| Nickel-Chromium (NiCr) Alloys | Up to ~1200°C | Durable, consistent performance | Air |

| Silicon Carbide (SiC) | Up to 1600°C | High thermal conductivity, shock-resistant | Air |

| Refractory Metals (e.g., Molybdenum, Tungsten) | Above 1600°C | Extreme temperatures, oxidizes in air | Vacuum or inert gas |

| Advanced Ceramics | Varies by composition | Efficient heat transfer, versatile | Depends on type |

Struggling to select the right high-temperature heating element for your lab's furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental needs for reliable, efficient heating. Contact us today to discuss how we can enhance your thermal processes!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How do ceramic infrared heaters transfer heat to the object being heated? Efficient, Direct Radiant Heating Explained

- What causes spalling in MoSi2 heating elements and how can it be addressed? Prevent Damage and Extend Element Life

- Why are fine-wire Type-R thermocouples necessary for measuring gas temperature distributions? Precision Lab Insights

- What advantages do high-purity alumina ceramic tubes offer for high-temperature furnace applications? Boost Efficiency and Safety

- How can high temperature heating elements be customized for different applications? Tailor Elements for Peak Performance

- What are the thermal properties of molybdenum? Mastering Extreme Heat Applications

- What makes nickel alloys suitable for industrial heating applications? Discover Their High-Temp Strength & Corrosion Resistance

- Why is flexible graphite paper used in Barium Titanate SPS? Optimize Tooling Life and Heat Distribution