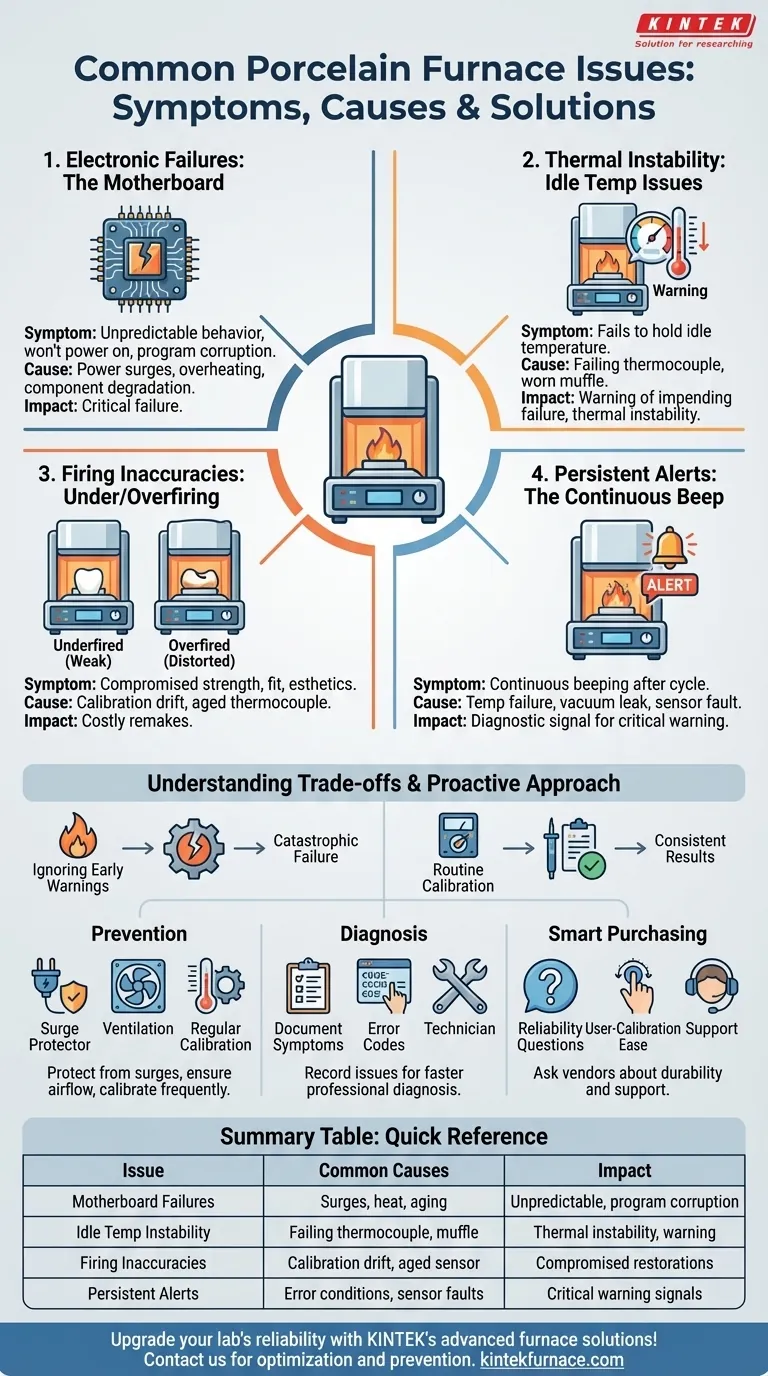

When a porcelain furnace malfunctions, it directly impacts the quality of your restorations and the efficiency of your workflow. The most commonly reported issues are frequent motherboard failures, an inability to hold stable idle temperatures between cycles, persistent beeping alerts after a program finishes, and significant firing inaccuracies where porcelain is either underfired or overfired compared to expected results.

These are not isolated annoyances but symptoms of deeper electronic and thermal regulation failures. Understanding the root cause of each issue is the key to moving from reactive repairs to proactive maintenance and ensuring consistent, high-quality results.

Diagnosing Critical Furnace Failures

Each common problem points to a specific type of failure within the furnace's complex system. Identifying the symptom is the first step toward a correct diagnosis and resolution.

Electronic Failures: The Motherboard

The motherboard is the brain of the furnace, controlling every parameter from temperature ramp rates to vacuum levels.

Frequent or premature motherboard failure is a critical issue. It can be caused by power surges, internal overheating due to poor ventilation, or simple component degradation over time. A failing motherboard can manifest in unpredictable ways, including a complete refusal to power on, corrupted firing programs, or other erratic behavior.

Thermal Instability: Temperature Control Issues

A furnace that fails to hold its idle temperature after a firing cycle is often showing the first sign of a more significant thermal problem.

This indicates an issue with the furnace's ability to regulate its own heat. The cause is typically a failing thermocouple (the sensor that reads the temperature) or a worn-out muffle (the heating element and insulation). The system is struggling to maintain a steady state, which is a clear warning of impending failure during a critical firing cycle.

Firing Inaccuracies: Underfiring and Overfiring

Perhaps the most costly issue is a furnace that underfires or overfires the porcelain. This compromises the strength, fit, and esthetics of the final restoration.

This problem is almost always tied to calibration drift. The temperature reported on the screen does not match the true temperature inside the muffle. The thermocouple may have aged and is no longer reading accurately, or the electronic controller needs to be recalibrated to match the sensor's current output.

Persistent Alerts: The Continuous Beep

A continuous beeping sound after a cycle is more than an annoyance; it is a diagnostic signal.

The furnace is attempting to communicate an error condition or an unexpected result from the previous program. This could be a failure to reach the target temperature, a vacuum leak, or another sensor fault. Simply silencing the alarm without investigating the cause means ignoring a critical warning.

Understanding the Trade-offs: Prevention vs. Repair

Managing a porcelain furnace effectively involves balancing the cost and effort of maintenance against the high cost of unexpected downtime and failed restorations.

The Cost of Ignoring Early Warnings

Small irregularities, like a slight temperature overshoot or a longer-than-usual cooldown, are early indicators of component wear. Ignoring them can lead to a catastrophic failure mid-cycle, ruining valuable work and causing significant delays.

The Critical Role of Calibration

Routine calibration is not an optional maintenance step. It is the single most effective defense against the costly problem of inaccurate firing. Verifying your furnace's temperature with a known standard ensures that your firing programs produce predictable and consistent results.

External Factors: Power and Environment

The operating environment plays a significant role in the longevity of furnace electronics. Using a high-quality surge protector or an uninterruptible power supply (UPS) can prevent catastrophic damage to the motherboard from electrical grid fluctuations. Likewise, ensuring the furnace has adequate ventilation minimizes heat stress on all electronic components.

A Proactive Approach to Furnace Reliability

By understanding these common failure points, you can shift from a reactive to a proactive strategy, maximizing both the life of your equipment and the quality of your work.

- If your primary focus is preventing unexpected failures: Invest in a quality surge protector and ensure proper ventilation, and most importantly, perform regular temperature calibrations.

- If your primary focus is diagnosing an existing problem: Document the specific symptoms and error codes, as this will help a technician quickly identify whether the issue stems from the thermocouple, muffle, or motherboard.

- If your primary focus is purchasing new equipment: Ask vendors directly about the reliability of their motherboards, the ease of user-calibration, and the availability of technical support for troubleshooting.

Mastering your equipment begins with understanding its potential points of failure.

Summary Table:

| Issue | Common Causes | Impact |

|---|---|---|

| Frequent motherboard failures | Power surges, poor ventilation, component degradation | Unpredictable behavior, program corruption, refusal to power on |

| Inability to hold idle temperatures | Failing thermocouple, worn-out muffle | Thermal instability, warning of impending failure |

| Firing inaccuracies (underfiring/overfiring) | Calibration drift, aged thermocouple | Compromised strength, fit, and esthetics of restorations |

| Persistent beeping alerts | Error conditions, sensor faults, vacuum leaks | Diagnostic signals for critical warnings |

Upgrade your lab's reliability with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, minimizing downtime and enhancing restoration quality. Contact us today to discuss how we can optimize your workflow and prevent costly failures!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations