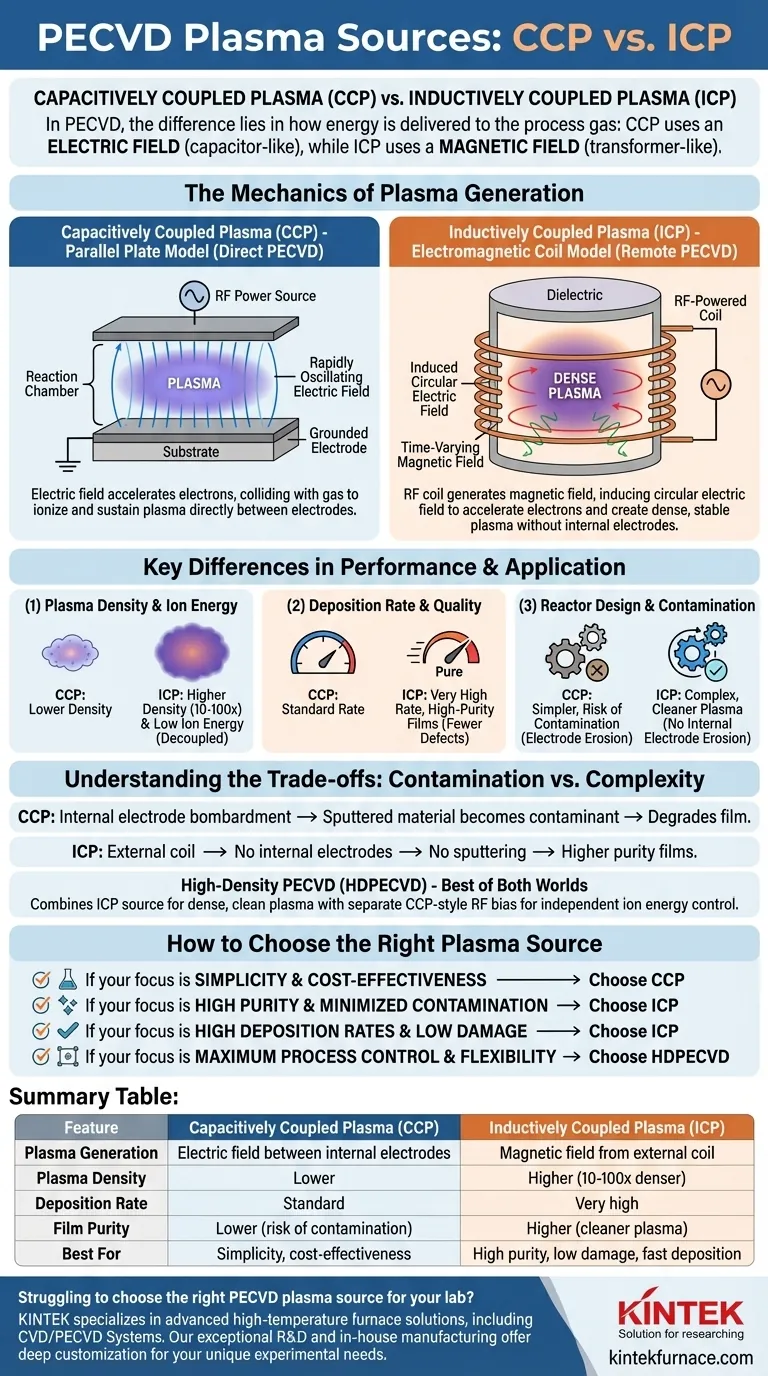

In the context of PECVD, the primary difference between capacitively coupled and inductively coupled plasmas lies in how energy is delivered to the process gas. Capacitively Coupled Plasma (CCP) uses an electric field generated between two internal electrodes, much like a capacitor. In contrast, Inductively Coupled Plasma (ICP) uses a magnetic field generated by an external coil to induce an electrical current within the gas, similar to a transformer.

The choice between CCP and ICP is a fundamental trade-off between simplicity and performance. CCP offers a simpler, more common design, while ICP provides a denser, purer plasma that enables higher quality films and faster deposition rates.

The Mechanics of Plasma Generation

To choose the right method, you must first understand how each one energizes a gas into a plasma state. The mechanism directly impacts the resulting film's properties.

Capacitively Coupled Plasma (CCP): The Parallel Plate Model

A CCP reactor is the most common design in PECVD, often referred to as a direct PECVD system. It operates using two parallel metal plates, or electrodes, inside the reaction chamber.

One electrode is grounded, while the other is connected to a radio-frequency (RF) power source. This creates a rapidly oscillating electric field between the plates.

This field accelerates free electrons in the gas, causing them to collide with and ionize gas molecules, initiating and sustaining the plasma directly between the electrodes where the substrate sits.

Inductively Coupled Plasma (ICP): The Electromagnetic Coil Model

An ICP reactor typically features an RF-powered coil wrapped around a dielectric (non-conductive) portion of the chamber. This design is often called a remote PECVD system because the power source is outside the chamber.

The RF current flowing through the coil generates a time-varying magnetic field. This magnetic field, in turn, induces a circular electric field inside the chamber.

This induced electric field accelerates electrons and creates a very dense, stable plasma without any internal electrodes.

Key Differences in Performance and Application

The physical differences in how CCP and ICP systems are built lead to significant variations in performance, making each suitable for different goals.

Plasma Density and Ion Energy

ICP generates a significantly higher density plasma (10 to 100 times denser) than CCP. This means there are far more ions, electrons, and reactive chemical species available for the deposition process.

Crucially, ICP can create this high-density plasma at low ion energy. This decouples plasma density from the energy of ions hitting the substrate, which is a major advantage.

Deposition Rate and Quality

The high density of reactive species in an ICP system allows for very high deposition rates, making it ideal for mass production environments like solar cell manufacturing.

Because the electrodes are outside the chamber, ICP systems produce a cleaner plasma. This results in higher-purity films with fewer defects.

Reactor Design and Contamination

CCP systems are mechanically simpler and more common. However, the internal powered electrode is in direct contact with the plasma.

ICP systems are more complex, but their external coil design physically separates the power source from the plasma.

Understanding the Trade-offs

The most critical trade-off between these two methods is the balance between contamination and complexity.

The Contamination Problem in CCP

In a CCP system, ions from the plasma are accelerated toward the powered electrode. This bombardment can sputter (erode) material from the electrode itself.

This sputtered material becomes a contaminant, which can be incorporated into the growing film, degrading its electrical or optical properties.

The Advantage of ICP's "Cleaner" Plasma

Because an ICP's energy source is an external coil, there are no electrodes inside the chamber to erode.

This complete elimination of electrode sputtering is the primary reason ICP is known for producing higher-purity films and is the preferred method when contamination control is critical.

High-Density PECVD (HDPECVD): The Best of Both Worlds

Advanced systems, known as High-Density Plasma PECVD (HDPECVD), often combine both techniques.

An ICP source is used to generate a high-density, clean plasma for rapid deposition. Simultaneously, a separate RF bias is applied to the substrate holder using a CCP-like configuration to independently control the energy of ions bombarding the film, offering maximum process control.

How to Choose the Right Plasma Source

Your choice depends entirely on your project's specific priorities regarding film quality, throughput, and cost.

- If your primary focus is simplicity and cost-effectiveness for general applications: CCP is the established, straightforward, and most common choice.

- If your primary focus is high film purity and minimizing contamination: ICP is the superior option due to its external, non-contact electrode design.

- If your primary focus is achieving high deposition rates with low substrate damage: ICP's high-density, low-ion-energy plasma is ideal for efficient mass production.

- If your primary focus is maximum process control and performance: A hybrid HDPECVD system combining an ICP source with a CCP-style bias offers the most flexibility.

Ultimately, understanding the plasma generation mechanism empowers you to control the fundamental properties of your deposited material.

Summary Table:

| Feature | Capacitively Coupled Plasma (CCP) | Inductively Coupled Plasma (ICP) |

|---|---|---|

| Plasma Generation | Electric field between internal electrodes | Magnetic field from external coil |

| Plasma Density | Lower | Higher (10-100x denser) |

| Deposition Rate | Standard | Very high |

| Film Purity | Lower (risk of contamination) | Higher (cleaner plasma) |

| Best For | Simplicity, cost-effectiveness | High purity, low damage, fast deposition |

Struggling to choose the right PECVD plasma source for your lab? KINTEK specializes in advanced high-temperature furnace solutions, including CVD/PECVD Systems. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to precisely match your unique experimental needs—whether you require the simplicity of CCP or the high-performance benefits of ICP for superior film quality and faster deposition rates. Contact us today to discuss how our tailored solutions can enhance your research and production outcomes!

Visual Guide

Related Products

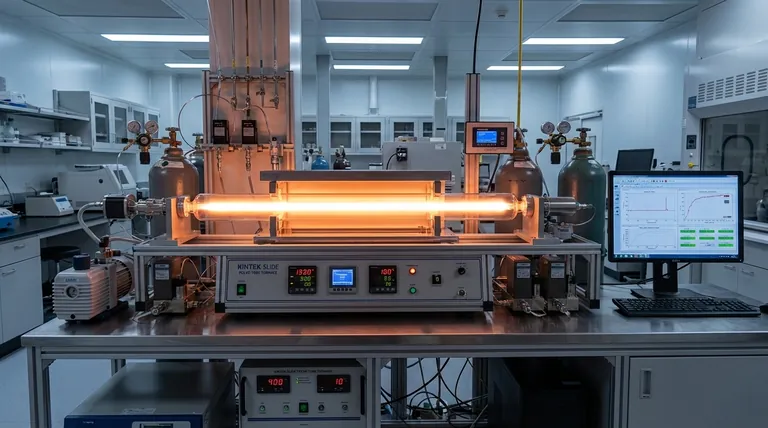

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is PECVD specification? A Guide to Choosing the Right System for Your Lab

- What are the advantages of using CVD? Achieve High-Purity, Conformal Thin Films for Your Applications

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process