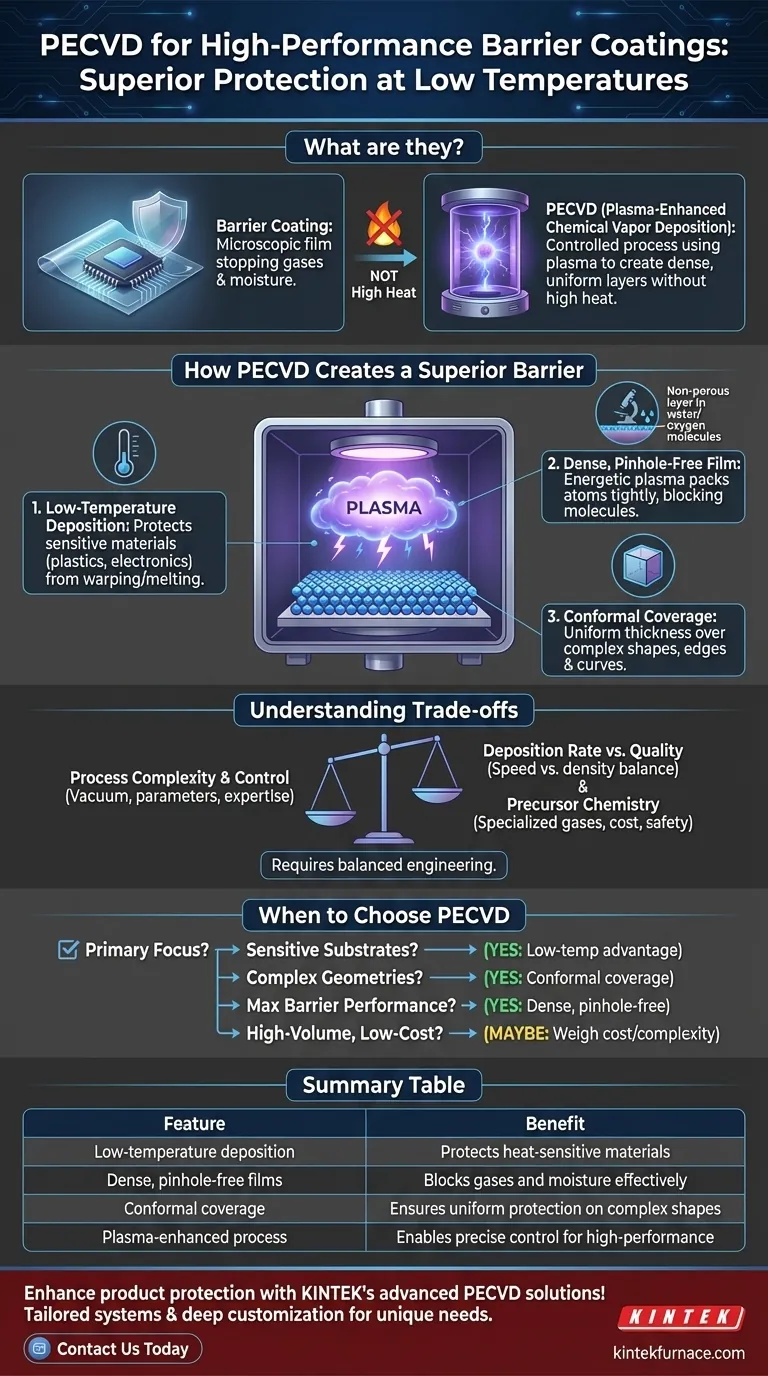

In short, a barrier coating is a microscopic film designed to stop gases like oxygen or water vapor from passing through and damaging a product. Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a highly controlled manufacturing process used to apply these coatings, creating an exceptionally dense and uniform protective layer without using high, damaging heat.

The core advantage of using PECVD for barrier coatings is its ability to deposit highly effective, pinhole-free protective layers at low temperatures. This makes it possible to protect sensitive materials like plastics and electronics that would be destroyed by traditional high-heat coating methods.

How PECVD Creates a Superior Barrier

Unlike conventional methods that rely on extreme heat, PECVD uses an energized gas, or plasma, to drive the chemical reactions that form the coating. This fundamental difference is what gives the process its unique advantages.

The Role of Low-Temperature Deposition

The most significant benefit of PECVD is its low-temperature operation. High heat can warp, melt, or otherwise degrade many materials, especially polymers and fully assembled electronic devices.

Because PECVD does not require a furnace, it can safely apply a high-performance barrier coating to a vast range of heat-sensitive substrates, opening up new possibilities for product protection.

Creating a Dense, Pinhole-Free Film

The plasma environment provides the energy needed to create a coating that is exceptionally dense and non-porous. The energetic particles in the plasma help arrange the deposited atoms into a tightly packed structure.

This density is the key to an effective barrier. It physically blocks molecules like water and oxygen from finding a path through the coating to the underlying material, preventing corrosion or degradation.

Achieving Conformal Coverage

Many products have complex shapes with edges, curves, and internal surfaces. PECVD excels at conformal coating, meaning it deposits a layer of uniform thickness over the entire exposed surface of an object.

This uniformity ensures there are no weak spots, providing comprehensive protection that line-of-sight deposition methods cannot easily achieve.

Understanding the Trade-offs

While powerful, PECVD is a sophisticated process with specific considerations. Understanding its limitations is crucial for making an informed decision.

Process Complexity and Control

PECVD is not a simple "dip and dry" process. It requires sophisticated vacuum chambers and precise, computer-aided control over multiple variables, including gas pressure, flow rates, and plasma power.

Achieving a high-quality, repeatable barrier coating depends on meticulously fine-tuning these parameters, which requires significant process expertise.

Deposition Rate vs. Film Quality

There is often a trade-off between the speed of deposition and the ultimate quality of the barrier film. Rushing the process can sometimes result in a more porous, less effective coating.

Engineers must find the optimal balance that meets both the production throughput requirements and the necessary performance specifications for the barrier.

Precursor Gas Chemistry

The "Chemical Vapor" in PECVD refers to the precursor gases that provide the atomic building blocks for the coating. The choice of these gases is critical to the film's final properties.

These specialized gases can be expensive, and handling them requires strict safety protocols, which adds to the overall operational cost and complexity.

Making the Right Choice for Your Goal

Deciding if PECVD is the correct solution depends entirely on your specific material, product geometry, and performance requirements.

- If your primary focus is protecting sensitive substrates: PECVD's low-temperature process is its defining advantage for materials like polymers, flexible circuits, or assembled electronics.

- If your primary focus is coating complex geometries: PECVD's conformal nature ensures uniform protection over intricate shapes, which is superior to many competing technologies.

- If your primary focus is achieving maximum barrier performance: The plasma-assisted process enables precise control to create exceptionally dense and pinhole-free films ideal for preventing gas and moisture diffusion.

- If your primary focus is extremely high-volume, low-cost production: You must carefully weigh the cost and complexity of PECVD against the level of barrier protection your product truly requires.

By understanding these principles, you can determine if PECVD is the right tool to enhance your product's durability, reliability, and lifespan.

Summary Table:

| Feature | Benefit |

|---|---|

| Low-temperature deposition | Protects heat-sensitive materials like plastics and electronics |

| Dense, pinhole-free films | Blocks gases and moisture effectively |

| Conformal coverage | Ensures uniform protection on complex shapes |

| Plasma-enhanced process | Enables precise control for high-performance barriers |

Enhance your product's protection with KINTEK's advanced PECVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for barrier coatings on sensitive substrates. Contact us today to discuss how our expertise can boost your durability and reliability!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temp, High-Quality Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition