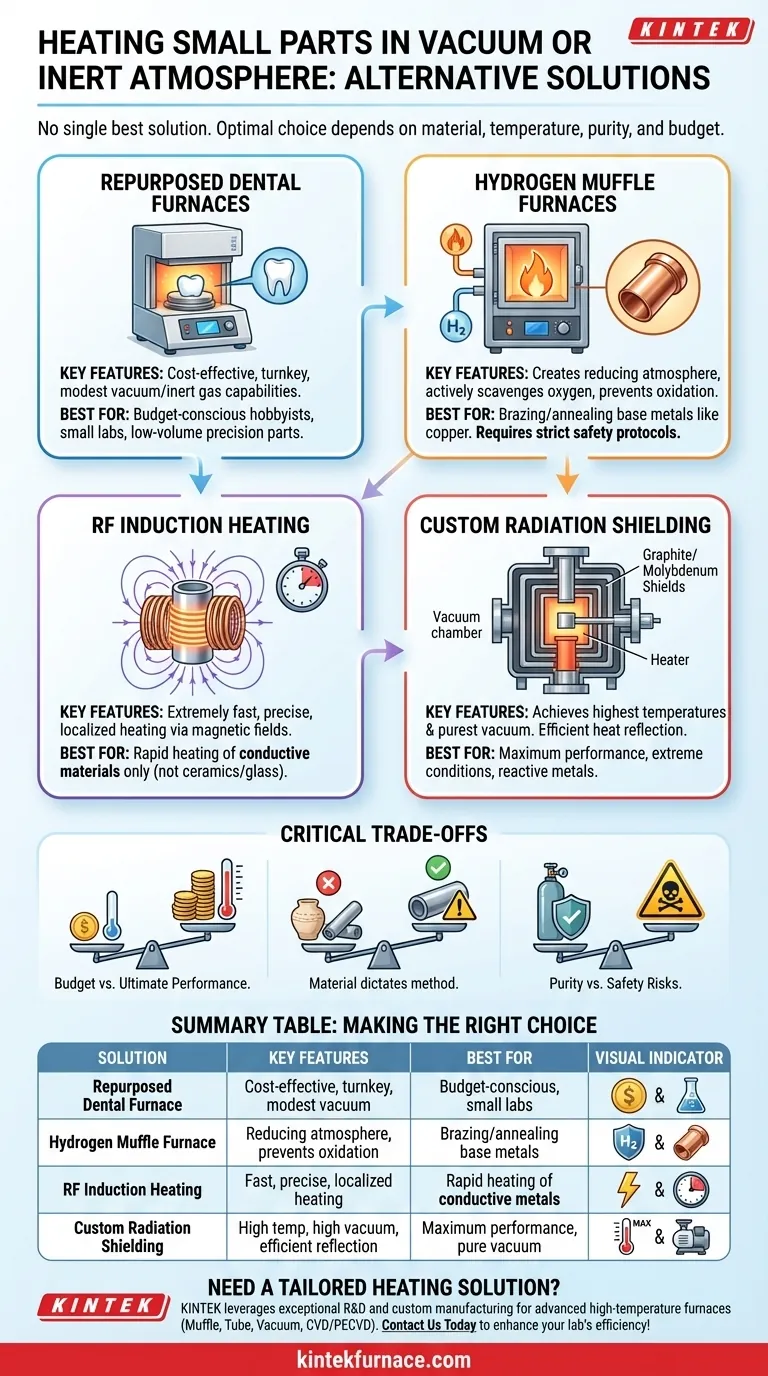

For heating small parts in a vacuum or inert atmosphere, several effective alternatives to large industrial furnaces exist. These include specialized equipment like hydrogen muffle furnaces and RF induction heaters, repurposed devices such as secondhand dental furnaces, and custom-built systems using graphite or molybdenum radiation shields within a water-cooled chamber.

The optimal solution depends entirely on your specific goal. Choosing the right method requires balancing your material type, required temperature, atmosphere purity, and budget, as there is no single best-for-all-cases answer.

Analyzing Off-the-Shelf and Repurposed Solutions

For many applications, a dedicated or repurposed furnace offers the most direct path to achieving your heating goals. These options trade some flexibility for ease of use and lower initial investment.

Repurposed Dental Furnaces

A secondhand dental furnace is an excellent and often overlooked option for small-scale work. These units are specifically designed for firing small, high-precision ceramic and metal parts (like crowns) at high temperatures.

Many models already include features for pulling a modest vacuum or purging with an inert gas like argon. They represent a cost-effective, turnkey solution for hobbyists and small labs.

Hydrogen Muffle Furnaces

A hydrogen muffle furnace is not just for creating an inert environment; it creates a reducing atmosphere. This is critical for processes like brazing or annealing copper and other base metals without oxidation.

The hydrogen actively scavenges oxygen at high temperatures, producing a bright, clean metal surface. However, this method requires strict safety protocols due to the flammability of hydrogen gas.

Exploring Specialized and Custom Heating Methods

When off-the-shelf equipment doesn't fit the need, specialized technologies or custom-built systems provide greater control and higher performance, albeit with more complexity.

RF Induction Heating

Radio-frequency (RF) induction is an extremely fast and efficient method for heating conductive materials. It uses a high-frequency magnetic field to induce electrical currents (eddy currents) directly within the metal part, causing it to heat from the inside out.

This technique allows for precise, localized heating in seconds and works well inside a vacuum or inert gas chamber. Its primary limitation is that it does not work on non-conductive materials like ceramics or glass.

Custom Radiation Shielding

For the highest temperatures and purest vacuum conditions, a custom setup is often necessary. This involves building a heating element inside a water-cooled vacuum chamber.

To reach extreme temperatures efficiently, the part and heating element are surrounded by heat radiation shields. These are thin sheets of a high-temperature material, typically graphite or molybdenum, which reflect thermal energy back toward the part, minimizing heat loss to the chamber walls. This is the principle used in high-performance laboratory and industrial vacuum furnaces.

Understanding the Critical Trade-offs

Each method comes with inherent compromises. Acknowledging these is key to avoiding costly mistakes and selecting the appropriate technology.

Cost vs. Capability

A repurposed dental furnace offers the lowest barrier to entry but may have limits on ultimate temperature and vacuum level. In contrast, a custom-built system with radiation shields offers maximum performance but requires significant investment in design, components, and assembly.

Material Compatibility

Your choice is heavily dictated by the part's material. RF induction is useless for ceramics. Graphite shields can contaminate certain reactive metals at very high temperatures. A hydrogen atmosphere can embrittle some alloys.

Atmosphere Control and Safety

A muffle furnace provides good atmosphere control via gas purging but cannot achieve a "hard" vacuum. A proper vacuum chamber with shields can reach very high vacuum levels. Furthermore, using flammable gases like hydrogen introduces a significant safety risk that must be professionally managed.

Making the Right Choice for Your Goal

To select the best path forward, align the technology's strengths with your primary objective.

- If your primary focus is budget and simplicity: Investigate secondhand dental furnaces, as they are a ready-made solution for small parts.

- If your primary focus is rapid heating of metal parts: RF induction offers unmatched speed and precision but is limited to conductive materials.

- If your primary focus is preventing oxidation on base metals: A hydrogen muffle furnace provides the necessary reducing atmosphere but demands rigorous safety procedures.

- If your primary focus is maximum temperature and vacuum purity: A custom-built system with molybdenum or graphite radiation shields offers the highest performance and control.

By understanding these core principles and trade-offs, you can confidently select the heating technology that best serves your specific project.

Summary Table:

| Solution | Key Features | Best For |

|---|---|---|

| Repurposed Dental Furnace | Cost-effective, turnkey, modest vacuum/inert gas | Budget-conscious hobbyists, small labs |

| Hydrogen Muffle Furnace | Reducing atmosphere, prevents oxidation | Brazing/annealing base metals like copper |

| RF Induction Heating | Fast, precise, localized heating | Rapid heating of conductive metals |

| Custom Radiation Shielding | High temperature, high vacuum, efficient heat reflection | Maximum performance with pure vacuum |

Need a tailored heating solution for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the function of laboratory high-temperature box furnaces in T6 aluminum treatment? Key to Material Strength

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- Why is a box muffle furnace used for the 800°C annealing of titanium LMD samples? Optimize Your Material Performance

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control