The primary advantages of a Rotary Tube Tilt Furnace stem from its unique ability to combine rotation and tilting. This dynamic system delivers superior material mixing for uniform heating, improved thermal efficiency that lowers energy consumption, and simplified material handling for both loading and discharging. It is specifically designed to overcome the common challenges of uneven treatment and clumping found in traditional static furnaces when processing powders and granules.

While traditional furnaces often struggle with uniform heat treatment for powders and granules, the Rotary Tube Tilt Furnace excels by using a combination of rotation and tilting. This dynamic control ensures exceptional process consistency, thermal efficiency, and operational flexibility, making it a superior choice for specific particulate applications.

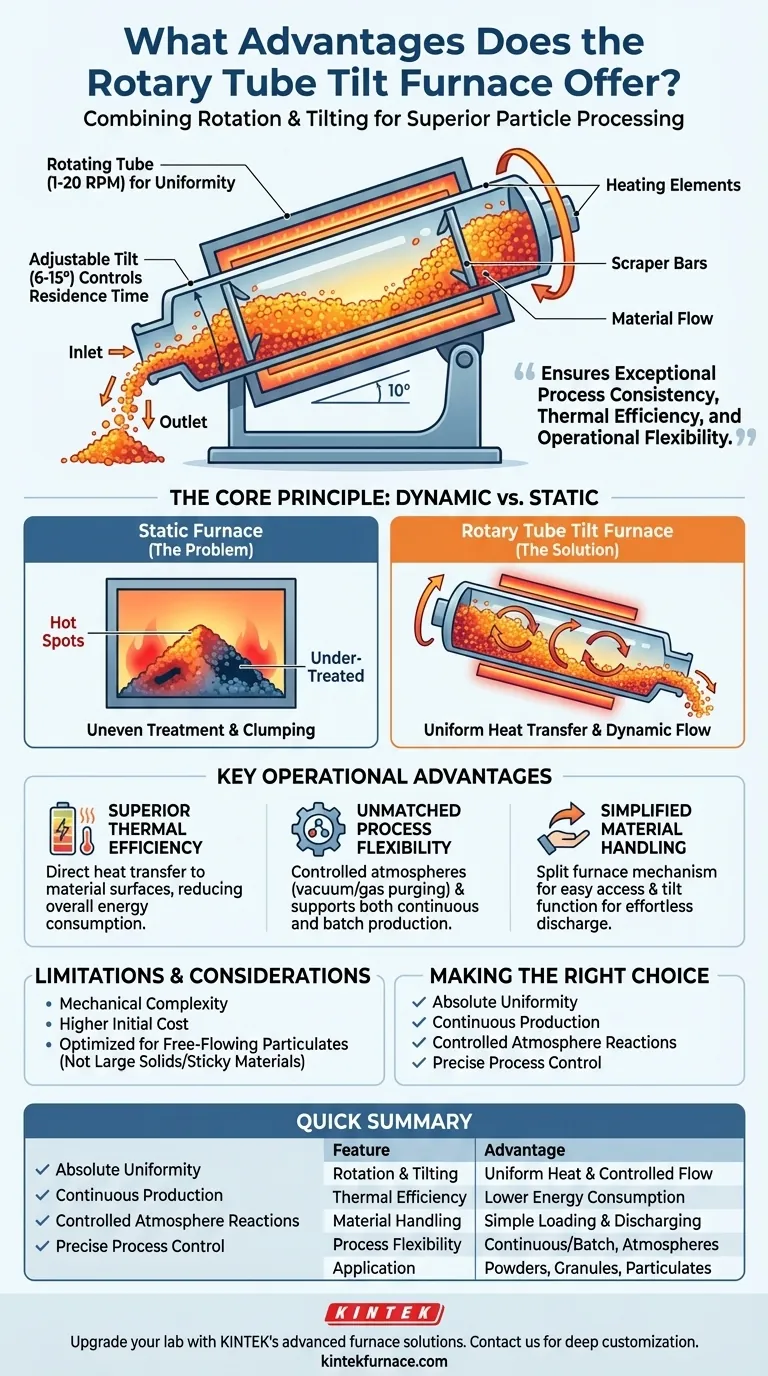

The Core Principle: Dynamic vs. Static Processing

The fundamental difference between a Rotary Tube Tilt Furnace (RTTF) and other types, like a static box or chamber furnace, is its active approach to material processing. It physically manipulates the material to achieve a better result.

How Rotation Ensures Uniformity

A static furnace heats material in a stationary pile. This often leads to "hot spots" where the outer layers are overheated while the core remains under-treated, causing inconsistent results and material agglomeration or clumping.

The RTTF's slow rotation (typically 1-20 RPM) constantly tumbles the material. This ensures every particle is repeatedly exposed to the heat source, guaranteeing highly uniform heat transfer throughout the entire batch.

Internal features like scraper bars can be included to further assist with mixing and prevent material from sticking to the tube walls.

How Tilting Controls Material Flow

The tilt functionality, usually adjustable between 6-15 degrees, gives you precise control over the material's residence time—the duration it spends within the furnace's heated zone.

A steeper angle results in a faster flow-through rate, which is ideal for continuous processing. A shallower angle increases the residence time, which is necessary for processes that require longer heat exposure.

The Synergy of Rotation and Tilt

Together, rotation and tilt provide a level of process control that is impossible to achieve in a static system. You can fine-tune the heat exposure (via rotation) and the process duration (via tilt) independently to perfect your thermal treatment.

Key Operational Advantages Explained

This dynamic design translates into several practical, high-impact benefits for industrial and laboratory processes.

Superior Thermal Efficiency

By constantly exposing new material surfaces to the heat source, the RTTF ensures that thermal energy is transferred directly and efficiently into the product. This prevents wasted energy and often leads to lower overall energy consumption compared to static furnaces.

Unmatched Process Flexibility

An RTTF is highly adaptable. It can be designed to operate with a controlled atmosphere, using gas purging systems or creating a vacuum for sensitive reactions like those involving catalysts or advanced materials.

Furthermore, its design allows for both continuous and batch production, providing flexibility to scale operations as needed.

Simplified Material Handling

The practical design makes operation much smoother. A split furnace mechanism allows the heating elements to open up, providing easy access for loading or changing the process tube.

When the process is complete, the tilt function is used to effortlessly discharge the finished material, streamlining the entire workflow.

Understanding the Trade-offs and Limitations

No technology is universally superior. It is critical to understand where an RTTF may not be the optimal choice.

Mechanical Complexity and Maintenance

The addition of rotating seals, a drive motor, and a tilting mechanism introduces more moving parts compared to a simple static furnace. This increases the potential need for maintenance and adds mechanical complexity.

Higher Initial Cost

As a specialized piece of equipment with more complex engineering, a Rotary Tube Tilt Furnace typically carries a higher upfront investment cost than a standard box furnace of a similar size.

Material Suitability

This furnace design is optimized for powders, granules, and other free-flowing particulates. It is generally unsuitable for large solid objects, materials that may melt into a liquid state, or extremely sticky substances that could bind within the tube.

Making the Right Choice for Your Application

The decision to use a Rotary Tube Tilt Furnace should be driven by the specific demands of your process.

- If your primary focus is absolute process uniformity: The RTTF is the ideal choice for applications like calcination, sintering, or drying where every particle must receive identical heat treatment.

- If your primary focus is moving to continuous production: The tilt-controlled flow makes this furnace a perfect solution for transitioning from smaller, inefficient batch processes to a streamlined continuous workflow.

- If your primary focus is reactions in a controlled atmosphere: The sealed tube design is far superior to a standard box furnace for processes requiring specific gas environments or vacuums.

- If your primary focus is simplicity and low cost for non-particulate materials: A traditional static or chamber furnace will likely be a more straightforward and cost-effective solution.

Ultimately, investing in a Rotary Tube Tilt Furnace is a decision to prioritize precise process control and final material consistency.

Summary Table:

| Feature | Advantage |

|---|---|

| Rotation and Tilting | Ensures uniform heat distribution and controlled material flow |

| Thermal Efficiency | Reduces energy consumption with direct heat transfer |

| Material Handling | Simplifies loading and discharging with split furnace and tilt functions |

| Process Flexibility | Supports continuous/batch operations and controlled atmospheres |

| Application Suitability | Ideal for powders, granules, and free-flowing particulates |

Upgrade your lab's thermal processing with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Rotary Tube Tilt Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior uniformity and efficiency. Contact us today to discuss how we can optimize your processes and deliver tailored solutions!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing