For material research, a Chemical Vapor Deposition (CVD) tube furnace offers a powerful combination of precise environmental control, operational flexibility, and high efficiency. Its ability to create a highly uniform and stable thermal environment, combined with strict atmospheric control, makes it an indispensable tool for synthesizing advanced materials, from thin films to nanomaterials.

The core value of a CVD tube furnace is not just heating materials, but creating an exact, repeatable micro-environment. This precision is what enables researchers to control material synthesis at a fundamental level, turning theoretical possibilities into tangible, high-performance materials.

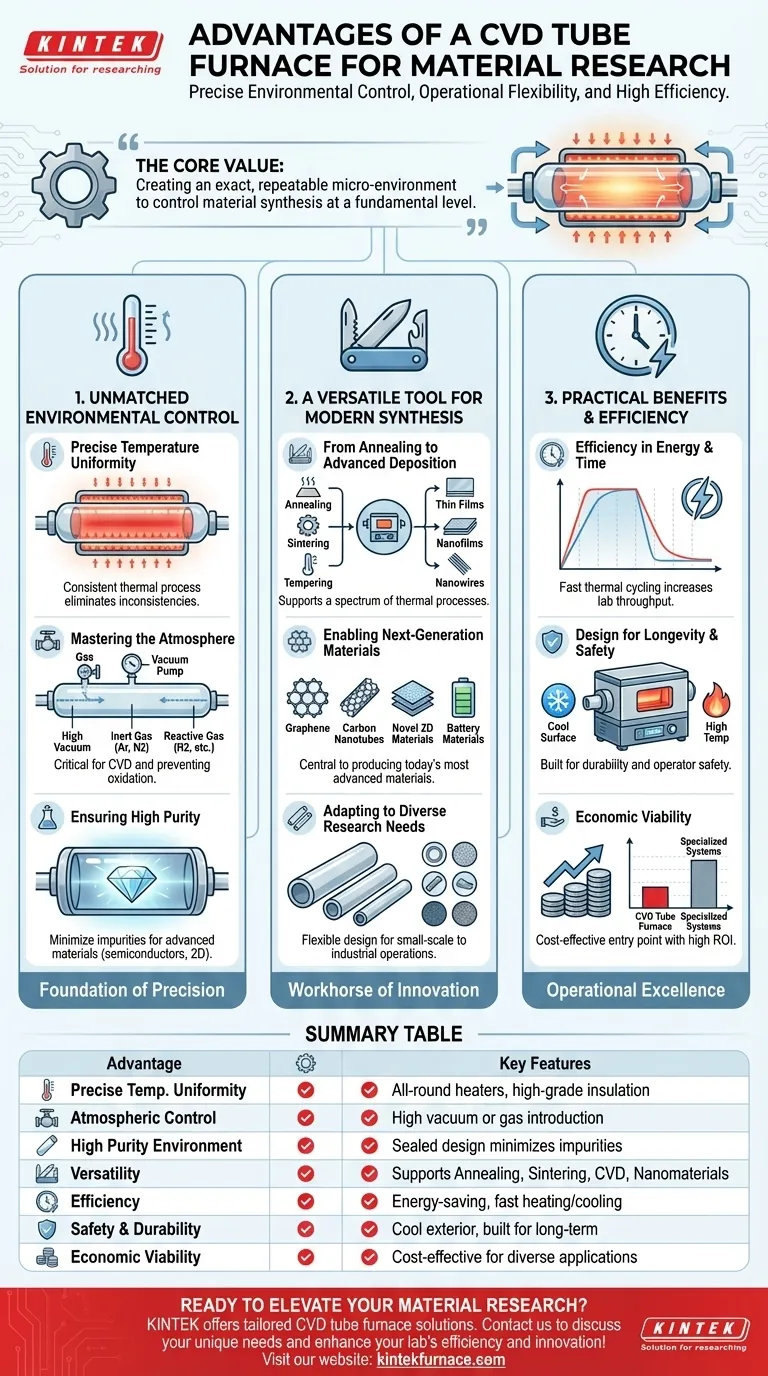

The Foundation: Unmatched Environmental Control

A furnace's primary job is to control the synthesis environment. The CVD tube furnace excels at this through a multi-faceted approach, giving researchers command over the most critical variables in material creation.

Achieving Precise Temperature Uniformity

A key advantage is the exceptional temperature uniformity across the entire sample. This is achieved through a design that often includes powerful, all-round heaters and high-grade alumina fiber insulation.

This uniform heating ensures that the entire material undergoes the same thermal process, eliminating inconsistencies and leading to predictable, repeatable results—a requirement for high-quality research.

Mastering the Atmosphere

Beyond heat, the furnace allows for rigorous atmospheric control. Researchers can operate under high vacuum or introduce specific gases to create an inert or reactive environment.

This capability is fundamental for processes like Chemical Vapor Deposition (CVD), where precursor gases must react in a controlled space, as well as for preventing unwanted oxidation during high-temperature annealing or sintering.

Ensuring High Purity

The sealed furnace tube and controlled atmosphere create a high-purity environment. This is critical for synthesizing advanced materials like semiconductors or 2D materials, where even minute impurities can drastically alter the final properties.

A Versatile Tool for Modern Material Synthesis

The controlled environment of a CVD tube furnace makes it suitable for an astonishingly wide range of applications, establishing it as a workhorse in both academic labs and industrial R&D.

From Annealing to Advanced Deposition

The furnace supports a spectrum of thermal processes. These include fundamental techniques like annealing, sintering, and tempering to modify material properties.

More importantly, it is purpose-built for advanced synthesis methods like growing thin films, preparing nanofilms, and fabricating nanowires.

Enabling Next-Generation Materials

This versatility makes it central to the production of today's most advanced materials. Researchers rely on CVD tube furnaces to synthesize graphene, carbon nanotubes, and other novel 2D materials.

It is also widely used for processing battery materials, where precise sintering and drying conditions directly impact performance and longevity.

Adapting to Diverse Research Needs

CVD tube furnaces are not a one-size-fits-all solution. They are designed for flexibility, with different furnace tube materials and diameters available to accommodate diverse chemicals and sample sizes. This adaptability supports everything from small-scale exploratory research to larger, periodic industrial operations.

Understanding the Practical Benefits and Considerations

While its technical capabilities are paramount, the practical design features of a CVD tube furnace provide significant operational advantages that enhance its value in a research setting.

Efficiency in Energy and Time

Modern designs emphasize energy efficiency. The high-quality insulation and ability to achieve fast heating and cooling rates mean less power is consumed per cycle.

This rapid thermal cycling also reduces experiment time, increasing lab throughput and allowing researchers to iterate more quickly.

Design for Longevity and Safety

These furnaces are built for durability and continuous use. A common and important feature is a design that keeps the exterior surface cool even when the interior is at extremely high temperatures, enhancing operator safety.

Economic Viability

Compared to other highly specialized deposition systems, CVD tube furnaces often offer a more economical entry point for advanced material synthesis. Their reliability and versatility provide a high return on investment for research labs needing a multi-purpose thermal processing tool.

Making the Right Choice for Your Research Goal

To leverage a CVD tube furnace effectively, align its capabilities with your primary objective.

- If your primary focus is growing high-purity thin films or 2D materials: The precise atmospheric and temperature control is the most critical advantage you will leverage.

- If your primary focus is general thermal processing like annealing or sintering: The excellent temperature uniformity and energy efficiency will ensure consistent results and low operational costs.

- If your primary focus is exploring novel nanomaterials: The furnace's flexibility to handle different precursor gases, temperatures, and atmospheres makes it an ideal platform for experimentation.

Ultimately, the CVD tube furnace empowers material innovation by providing the stable, controlled, and versatile environment needed to build the materials of the future.

Summary Table:

| Advantage | Key Features |

|---|---|

| Precise Temperature Uniformity | All-round heaters, high-grade insulation for consistent heating |

| Atmospheric Control | High vacuum or gas introduction for inert/reactive environments |

| High Purity Environment | Sealed tube design to minimize impurities |

| Versatility | Supports annealing, sintering, CVD, and nanomaterial synthesis |

| Efficiency | Energy-saving design, fast heating/cooling for high throughput |

| Safety and Durability | Cool exterior surfaces, built for long-term use |

| Economic Viability | Cost-effective for diverse research applications |

Ready to elevate your material research with a tailored CVD tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our expertise can enhance your lab's efficiency and innovation!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- What temperature ranges can a CVD Tube Furnace achieve with different tube materials? Unlock High-Temp Precision for Your Lab

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision

- Which industries and research fields benefit from CVD tube furnace sintering systems for 2D materials? Unlock Next-Gen Tech Innovations

- What is the working principle of a CVD tube furnace? Achieve Precise Thin Film Deposition for Your Lab