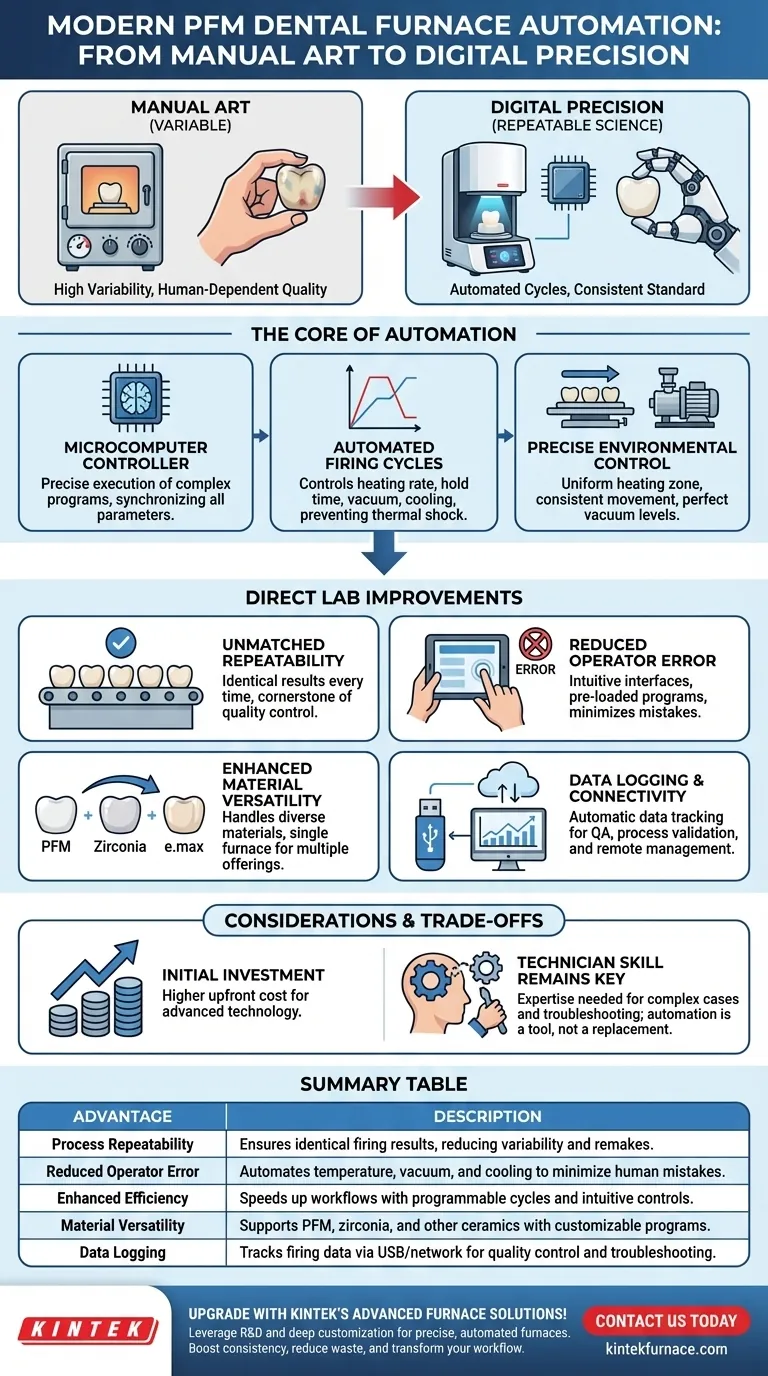

In short, modern porcelain-fused-to-metal (PFM) dental furnaces leverage automation to transform the firing process from a manual, variable craft into a precise, repeatable science. Advanced microcomputer controllers and programmable cycles automate every critical stage—from heating and vacuum to cooling—drastically reducing human error and ensuring that every restoration meets the exact same quality standard.

The central advantage of automation is not merely convenience; it is the systematic elimination of process variables. This leads directly to higher consistency, reduced material waste, fewer costly remakes, and a more efficient and profitable dental lab workflow.

The Core of Automation: From Manual Art to Digital Precision

Older furnaces required constant manual supervision, making the final quality highly dependent on an individual technician's skill and attention. Modern automation replaces this variability with digital certainty.

The Programmable Microcomputer Controller

The microcomputer controller is the brain of the modern furnace. It executes complex firing programs with flawless precision, something a human operator cannot consistently replicate.

These controllers manage all parameters simultaneously, ensuring the complex interplay between temperature, time, and vacuum is perfectly synchronized according to the material manufacturer's specifications.

Automated Firing Cycles

Automation governs the entire firing process. This includes pre-set and customizable programs that control the rate of heating, the target temperature and hold time, the application and release of vacuum, and the rate of cooling.

This removes guesswork and ensures that delicate materials like porcelain are not subjected to thermal shock, which could cause cracks or aesthetic flaws.

Precise Environmental Control

Modern furnaces use automation to create a perfectly uniform heating zone. This ensures that the entire restoration, regardless of its position on the tray, is fired at the same temperature.

Furthermore, features like motorized trays ensure smooth and consistent movement of the work into and out of the heat chamber, preventing jarring that could disturb porcelain placement. The system also maintains precise vacuum levels, critical for creating dense, void-free ceramic layers.

How Automation Directly Improves Lab Operations

The benefits of a digitally controlled process extend beyond the furnace itself, impacting the entire lab's efficiency and output quality.

Unmatched Process Repeatability

Once a firing program is set and validated, automation guarantees it can be run identically hundreds of times. This process repeatability is the cornerstone of quality control in a production environment.

It ensures that the first crown of the day has the exact same properties as the last, leading to predictable aesthetic results and mechanical strength.

Reduced Operator Error

Intuitive touch-screen interfaces simplify what was once a complex procedure. Technicians can select pre-loaded programs for specific materials or easily build custom cycles.

This lowers the technical barrier for new technicians and reduces the likelihood of costly errors, such as entering an incorrect temperature or hold time.

Enhanced Material Versatility

While the question is about PFM, most modern furnaces are multi-functional. Their programmable nature allows them to handle a wide range of materials, from traditional metal-ceramics to advanced all-ceramics like zirconia and lithium disilicate.

A single automated furnace can support diverse product offerings, making the lab more versatile and competitive.

Data Logging and Remote Management

Many advanced furnaces include USB or network connectivity (RS 232/485). This allows for automatic logging of all firing data, which is invaluable for quality assurance, process validation, and troubleshooting.

In some cases, it also enables remote monitoring or diagnostics, further improving operational efficiency.

Understanding the Trade-offs and Considerations

While the advantages are significant, a clear-eyed assessment requires acknowledging the potential downsides.

The Initial Investment Cost

The most significant barrier is the upfront cost. Modern, highly automated dental furnaces represent a substantial capital investment compared to older or more basic models.

Reliance on Technology

A high degree of automation also creates a reliance on the technology. An electronic failure, such as a malfunctioning sensor or a corrupted controller, can bring production to a complete halt until it is professionally serviced.

The Need for Technician Skill

Automation is a powerful tool, not a replacement for expertise. Over-reliance on default programs can be a pitfall. An expert technician is still required to understand the nuances of dental materials, troubleshoot firing issues, and develop custom programs for complex or challenging cases.

Making the Right Choice for Your Lab

An automated furnace is an investment in predictability and quality. The right choice depends on your lab's specific operational goals.

- If your primary focus is maximizing throughput and consistency: The investment in full automation is critical. Prioritize furnaces with robust programmable controllers and pre-set material libraries to minimize remakes and standardize quality.

- If your primary focus is expanding material offerings: Seek a versatile furnace with a high maximum temperature and proven programs for PFM, zirconia, e.max, and other popular ceramics.

- If you are a smaller lab with budget constraints: Prioritize core automation features. A furnace with reliable, programmable firing cycles is more important than advanced connectivity or the largest touch screen.

Ultimately, automation empowers your technicians to shift their focus from managing the machine to mastering the artistry of the restoration itself.

Summary Table:

| Advantage | Description |

|---|---|

| Process Repeatability | Ensures identical firing results every time, reducing variability and remakes. |

| Reduced Operator Error | Automates temperature, vacuum, and cooling to minimize human mistakes. |

| Enhanced Efficiency | Speeds up workflows with programmable cycles and intuitive controls. |

| Material Versatility | Supports PFM, zirconia, and other ceramics with customizable programs. |

| Data Logging | Tracks firing data via USB/network for quality control and troubleshooting. |

Upgrade your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precise, automated furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, boosting consistency, reducing waste, and enhancing profitability. Contact us today to discuss how our tailored solutions can transform your workflow!

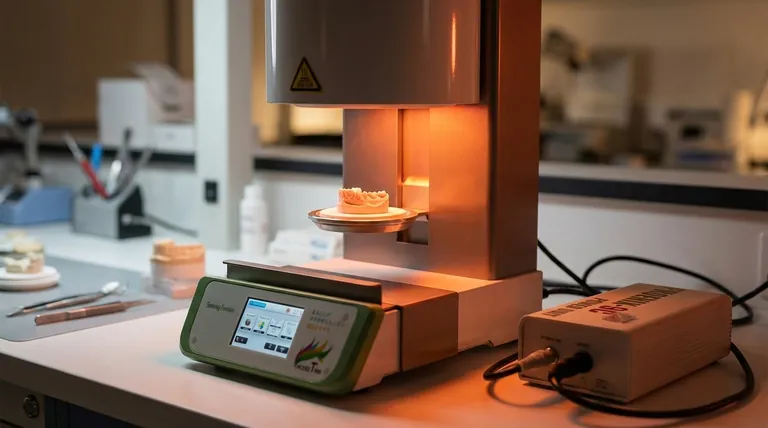

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision