The primary advantage of a solid-state power generator (SSPG) in an MPCVD system is its exceptional repeatability and stability. This means that when an SSPG unit is replaced, the system's operational parameters do not need to be recalibrated, because the new power source delivers precisely the same frequency and power characteristics as the old one. This ensures process consistency and dramatically reduces system downtime.

The core issue in any advanced deposition process is control. Moving from a traditional magnetron to a solid-state power generator is a shift from managing an unpredictable power source to leveraging a precise, stable, and digitally repeatable tool for manufacturing.

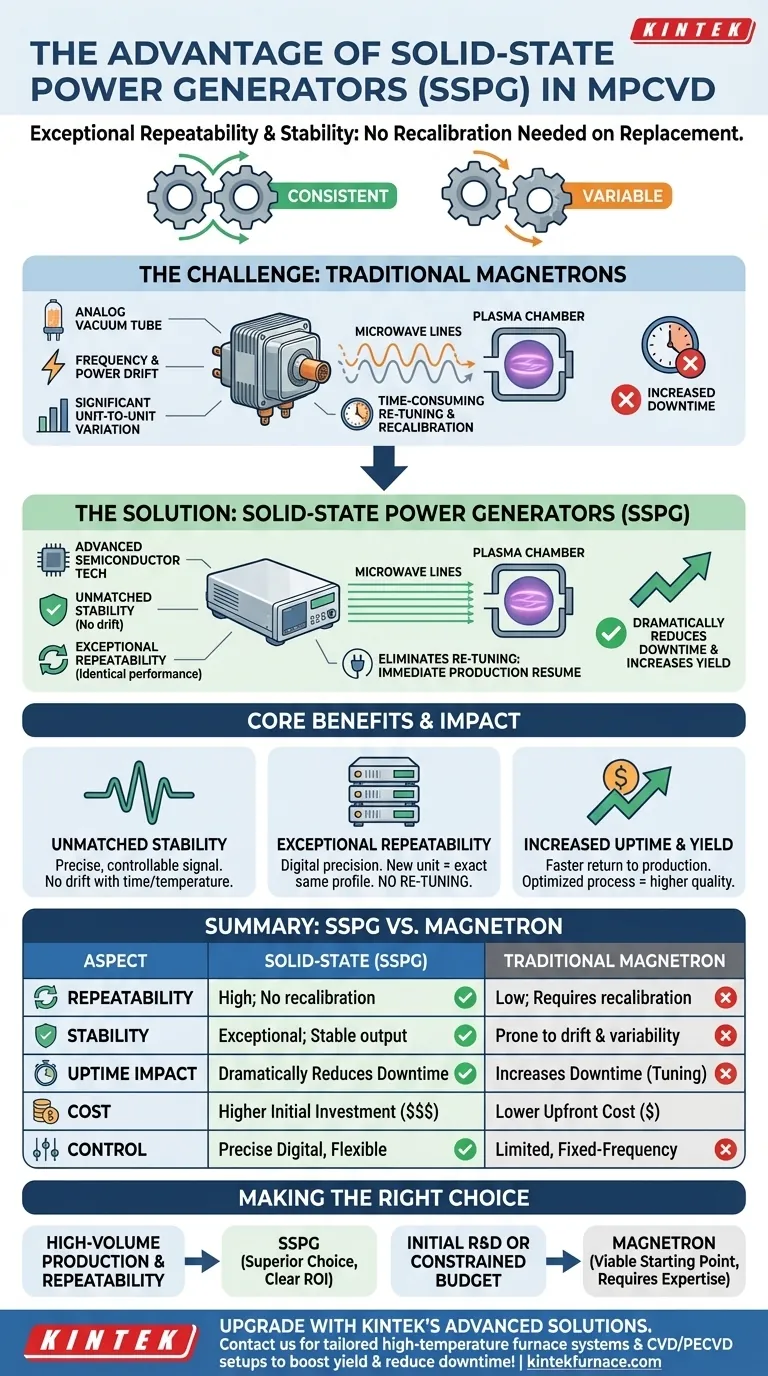

The Challenge of Power Delivery in MPCVD

Microwave Plasma-Enhanced Chemical Vapor Deposition (MPCVD) is a highly sensitive process, most notably used for growing high-quality synthetic diamonds. The quality, growth rate, and characteristics of the final product are directly dependent on the state of the plasma inside the reactor chamber.

The plasma's temperature, density, and spatial distribution are, in turn, dictated by the microwave energy that sustains it. Any instability or variation in the microwave power source will translate directly into an unstable process, leading to inconsistent results and lower yields.

The Problem with Traditional Magnetrons

For many years, magnetrons have been the standard power source for MPCVD systems. While functional, they introduce significant process variability.

A magnetron is an analog vacuum tube that generates microwaves. Its output frequency and power are subject to drift over its operational lifetime.

Crucially, there is significant unit-to-unit variation. Replacing a failed magnetron with a brand new one invariably changes the system's operating point, as the new tube will have slightly different power and frequency characteristics. This forces a complete system re-tuning and process recalibration, which is a time-consuming and expertise-intensive task.

How Solid-State Generators Solve the Problem

Solid-state power generators use advanced semiconductor technology (like GaN or LDMOS transistors) instead of a vacuum tube. This fundamental architectural difference provides solutions to the magnetron's inherent problems.

Unmatched Frequency and Power Stability SSPGs generate a pure, stable, and precisely controllable microwave signal. The frequency does not drift over time or with temperature changes, providing a consistent energy source for the plasma.

Exceptional Repeatability This is the key advantage highlighted by your question. Because SSPGs are manufactured with digital precision, every unit performs virtually identically. When one unit is replaced, the new one delivers the exact same power and frequency profile.

This eliminates the need for re-tuning the MPCVD system. The "working state" of the device remains unchanged, allowing production to resume immediately.

The Impact on Uptime and Yield For a production environment, this benefit is profound. Eliminating hours or days of recalibration after a power source failure drastically increases system uptime and overall equipment effectiveness (OEE).

Furthermore, the stable process environment created by an SSPG leads to higher yields of top-quality material, as process parameters remain perfectly optimized run after run.

Understanding the Trade-offs: SSPG vs. Magnetron

Choosing a power source is not just about performance; it involves balancing cost, complexity, and long-term goals.

The Cost Factor

The most significant advantage of magnetrons is their low upfront cost. A solid-state power generator represents a substantially higher initial capital investment.

Control and Flexibility

SSPGs offer near-infinite control over power and frequency, allowing for advanced process recipes that are impossible with a fixed-frequency magnetron. This includes rapid power pulsing and frequency tuning to optimize energy coupling with the plasma.

Durability and Lifespan

Magnetrons have a limited and somewhat unpredictable lifespan, with performance degrading over time. SSPGs, being solid-state devices, boast a much longer and more reliable operational life, which helps offset their higher initial cost over the long term.

Making the Right Choice for Your Process

The decision to use a solid-state generator depends entirely on your operational priorities.

- If your primary focus is high-volume production and process repeatability: The SSPG is the superior choice, as its stability and elimination of re-tuning downtime provide a clear return on investment.

- If your primary focus is initial R&D or operating on a constrained budget: A magnetron-based system can be a viable starting point, provided you have the in-house expertise and time to manage its tuning and calibration requirements.

Ultimately, investing in a solid-state power generator is an investment in process control and predictability.

Summary Table:

| Aspect | Solid-State Power Generator (SSPG) | Traditional Magnetron |

|---|---|---|

| Repeatability | High; no recalibration needed when replaced | Low; requires recalibration after replacement |

| Stability | Exceptional; stable frequency and power output | Prone to drift and variability |

| Uptime Impact | Dramatically reduces downtime | Increases downtime due to tuning |

| Cost | Higher initial investment | Lower upfront cost |

| Control | Precise digital control for advanced processes | Limited, fixed-frequency operation |

Upgrade your MPCVD system with KINTEK's advanced solid-state power solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature furnace systems, including CVD/PECVD setups. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing process control and efficiency. Contact us today to discuss how our tailored solutions can boost your yield and reduce downtime!

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What future potential does MPCVD technology hold for diamond synthesis? Unlock Next-Gen Electronics & Materials

- How should the cooling water system of MPCVD equipment be maintained? Ensure Stability and Longevity for Your Lab

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- What challenges does MPCVD face despite its advantages? Balancing Growth Rate, Quality, and Scalability

- What are the three types of CVD methods for synthesizing single crystal diamond? Compare MPCVD, DC-PJ CVD, and HFCVD for Your Lab

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth

- What are the key components that need regular cleaning in MPCVD equipment? Ensure Optimal Performance and Longevity

- What are some key features and benefits of the microwave plasma chemical vapor deposition system? Achieve Unmatched Material Synthesis