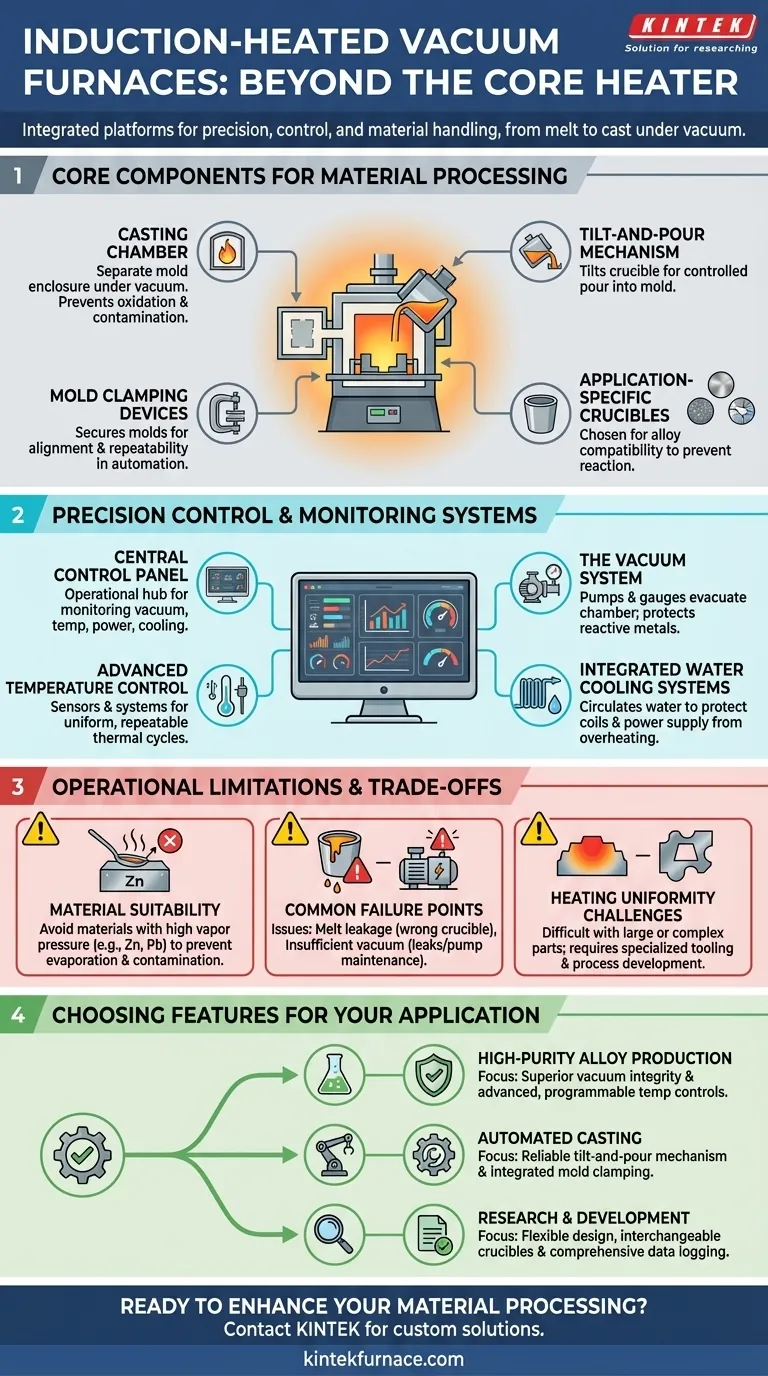

In addition to the core induction heating system, vacuum furnaces are equipped with a suite of features that transform them from simple heaters into comprehensive material processing systems. Key additions typically include a dedicated casting chamber for molds, a central control panel for process monitoring, and a tilt-and-pour mechanism for safely transferring molten metal.

The most important takeaway is that modern induction vacuum furnaces are not just about melting metal. They are integrated platforms designed for precision, control, and material handling, with features focused on managing the entire process from solid to final cast shape in a controlled vacuum environment.

Core Components for Material Processing

The features of an induction vacuum furnace are built around the need to melt, handle, and cast high-purity or reactive metals safely and efficiently.

The Casting Chamber

The casting chamber is a separate, connected enclosure designed to hold the mold. This allows the entire casting process to occur under vacuum, preventing the molten metal from being exposed to atmospheric oxygen or nitrogen.

The Tilt-and-Pour Mechanism

This is a critical mechanical feature that allows the entire crucible and coil assembly to be tilted. This enables a controlled, predictable pour of the molten metal from the crucible directly into the mold located in the casting chamber.

Mold Clamping Devices

For semi-automated or fully automated production environments, furnaces are often equipped with clamping devices. These securely hold the mold in place during the pour, ensuring alignment and improving process repeatability.

Application-Specific Crucibles

The crucible, which holds the metal charge, is a consumable but vital component. They are made from specific materials (like graphite, ceramic, or others) chosen based on their compatibility with the alloy being melted to prevent contamination or chemical reaction.

Precision Control and Monitoring Systems

Controlling the furnace environment is just as important as melting the metal. Modern systems rely on sophisticated control and support features to ensure process integrity.

The Central Control Panel

This is the operational hub of the furnace. It provides operators with a comprehensive interface to monitor and manage all critical parameters, including vacuum levels, temperature, power input, and cooling system status.

Advanced Temperature Control

Precision is achieved through a combination of temperature sensors, such as thermocouples, and computer-controlled power systems. These work together to maintain highly uniform heat distribution and enable repeatable, pre-programmed thermal cycles.

The Vacuum System

The vacuum system itself, comprised of pumps and gauges, is a cornerstone feature. Its primary role is to evacuate the chamber, protecting metals that have a high affinity for oxygen and nitrogen, such as superalloys, stainless steels, and reactive metals like zirconium.

Integrated Water Cooling Systems

Induction heating generates immense heat, not just in the metal charge but in the coil and power supply. A robust water cooling system is an essential, integrated feature that circulates water to protect these critical components from overheating and failure.

Understanding Operational Limitations and Trade-offs

While powerful, these furnaces are not a universal solution. Understanding their limitations is key to successful operation.

Material Suitability

These furnaces are not suitable for processing materials with a high saturated vapor pressure at melting temperature. Elements like zinc, lead, manganese, and even copper can evaporate under vacuum, altering the final alloy composition and contaminating the furnace interior.

Common Failure Points

The most common operational issues are directly tied to the furnace's features. Melt leakage can occur from an improper crucible choice, and an insufficient vacuum is a constant concern addressed by vigilant leak checking and pump maintenance.

Heating Uniformity Challenges

Achieving a perfectly uniform temperature can be difficult, especially with large or geometrically complex workpieces. This may require specialized tooling, careful process development, and advanced controller settings to manage.

Choosing Features for Your Application

The right set of features depends entirely on your end goal. Focus on the capabilities that directly support your primary process.

- If your primary focus is high-purity alloy production: Prioritize systems with superior vacuum integrity and advanced, programmable temperature controls.

- If your primary focus is automated casting: Emphasize mechanical features like a reliable tilt-and-pour mechanism and integrated mold clamping.

- If your primary focus is research and development: Seek a flexible furnace design that allows for interchangeable crucibles and provides comprehensive data logging from all sensors.

Ultimately, selecting the right induction vacuum furnace is about matching its integrated features to your specific material and processing requirements.

Summary Table:

| Feature | Description | Primary Benefit |

|---|---|---|

| Casting Chamber | Separate enclosure for molds under vacuum | Prevents oxidation and contamination of molten metals |

| Tilt-and-Pour Mechanism | Tilts crucible for controlled pouring | Enables safe, precise transfer to molds |

| Mold Clamping Devices | Secures molds during pouring | Improves alignment and process repeatability |

| Central Control Panel | Interface for monitoring and managing parameters | Ensures precise control over vacuum, temperature, and more |

| Advanced Temperature Control | Uses sensors and computer systems for uniform heating | Maintains consistent thermal cycles for repeatable results |

| Vacuum System | Pumps and gauges to evacuate chamber | Protects reactive metals from atmospheric gases |

| Water Cooling System | Circulates water to cool components | Prevents overheating of coils and power supplies |

Ready to enhance your material processing with a custom induction vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by deep customization capabilities to meet your unique experimental requirements. Contact us today to discuss how we can help you achieve superior precision and efficiency in your lab!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Induction Melting Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials