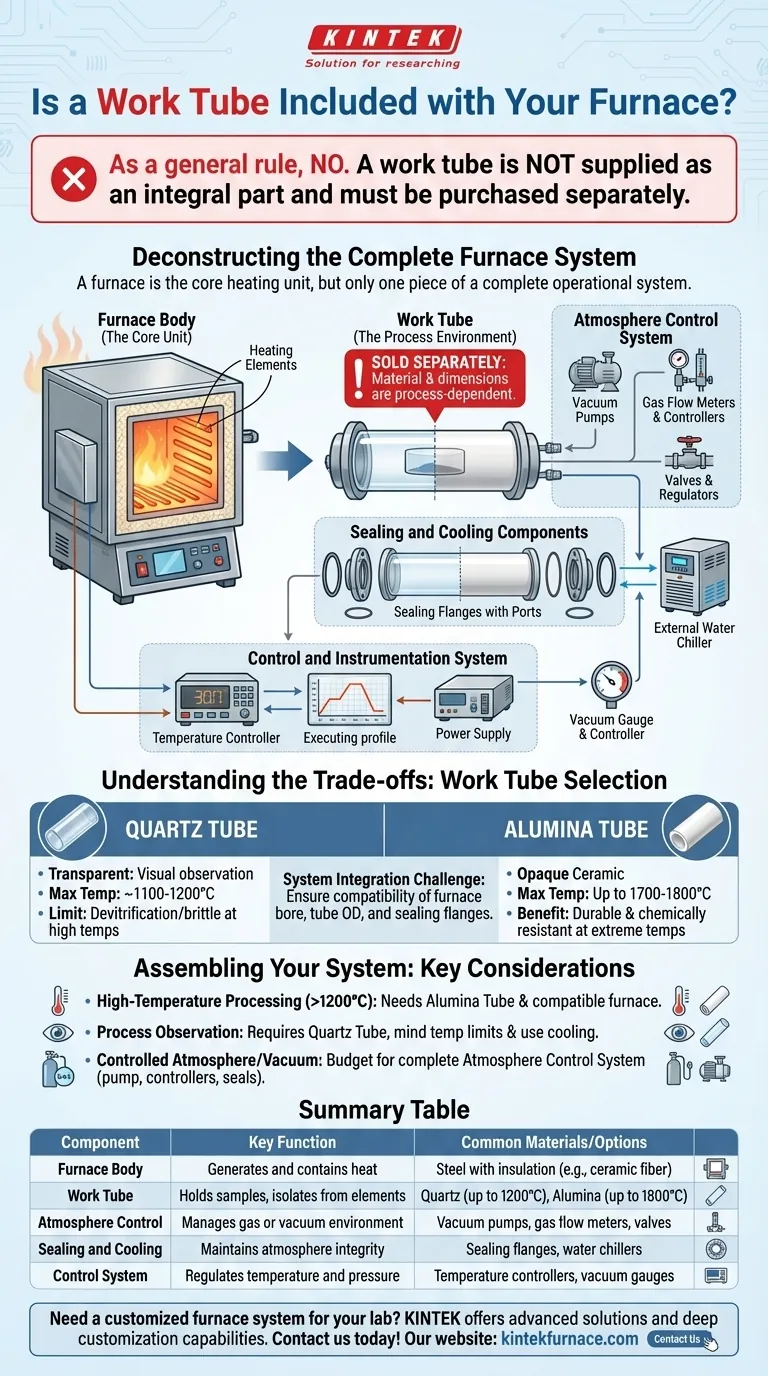

As a general rule, no. A work tube is not supplied as an integral part of a furnace and must be purchased separately. This is a deliberate design choice, as the correct tube material and dimensions are critically dependent on your specific application, including process temperature, chemical compatibility, and atmosphere requirements.

A furnace is the core heating unit, but it is only one piece of a complete operational system. You must plan to source several other critical components—most notably the work tube, sealing flanges, and atmosphere control system—to create a functional setup.

Deconstructing the Complete Furnace System

To understand why the work tube is separate, it helps to view the furnace not as a single product, but as a system of interconnected components. Each part serves a distinct function, and many must be selected specifically for your process goals.

The Furnace Body (The Core Unit)

This is the component most people think of as "the furnace." It is the insulated chamber containing the heating elements.

The furnace body is responsible for generating and containing heat. Its construction, often from steel with internal insulation like ceramic fiber or carbon felt, determines the furnace's maximum operating temperature and thermal efficiency.

The Work Tube (The Process Environment)

The work tube is the cylindrical chamber that slides through the furnace body. It contains your sample and isolates it from the heating elements and the outside air.

This component is sold separately because its material is process-dependent. The choice between materials like quartz, alumina, or mullite depends entirely on your required temperature and the chemical nature of your samples and process gasses.

The Atmosphere Control System

This system manages the environment inside the work tube. It is not a single part but a collection of devices.

Key components include vacuum pumps to remove air, gas flow meters or controllers to introduce specific gasses, and valves and regulators to manage pressure. This system is essential for running processes under vacuum or in a controlled inert or reactive gas atmosphere.

Sealing and Cooling Components

To maintain a controlled atmosphere, the ends of the work tube must be sealed. This is done with specialized sealing flanges or "masks."

These flanges often have ports for connecting vacuum pumps and gas lines. Because the seals (typically silicone or Viton O-rings) can degrade from heat, many systems require an external water chiller or a built-in water-cooling jacket to protect them.

The Control and Instrumentation System

This is the brain of the furnace. It consists of a temperature controller that executes your heating profile and a power supply for the heating elements.

If you are using a vacuum, a separate vacuum gauge and controller are also necessary to monitor and regulate the pressure inside the work tube.

Understanding the Trade-offs: Work Tube Selection

The decision to separate the work tube from the furnace purchase is rooted in critical performance trade-offs. Choosing the wrong tube can lead to failed experiments or equipment damage.

Quartz vs. Alumina

These are two of the most common tube materials, each with distinct advantages.

A quartz tube is transparent, allowing for direct visual observation of the process. However, it is generally limited to temperatures around 1100-1200°C and can devitrify or become brittle with prolonged use at high temperatures.

An alumina tube is an opaque ceramic that can withstand much higher temperatures, often up to 1700-1800°C. It is more durable and chemically resistant at extreme temperatures but does not allow for visual monitoring.

The System Integration Challenge

Purchasing components separately places the responsibility of system integration on you. You must ensure that the work tube's outer diameter is compatible with the furnace bore and that the sealing flanges are the correct size for the tube.

Failure to verify compatibility between the furnace, tube, and sealing system is a common and costly mistake. Always confirm the dimensions of all components before purchasing.

Assembling Your System: Key Considerations

To ensure you acquire a complete and functional system, align your component selection with your primary goal.

- If your primary focus is high-temperature processing (>1200°C): You will almost certainly need an alumina tube and a furnace rated for that temperature range.

- If your primary focus is process observation: A quartz tube is the correct choice, but you must operate within its temperature limitations and may need a cooling system to protect the seals.

- If your primary focus is a controlled atmosphere or vacuum: You must budget for a complete atmosphere control system, including a vacuum pump, flow controllers, and compatible sealing flanges.

By understanding each component's role, you can confidently specify and build a furnace system perfectly suited to your research or production goals.

Summary Table:

| Component | Key Function | Common Materials/Options |

|---|---|---|

| Furnace Body | Generates and contains heat | Steel with insulation (e.g., ceramic fiber) |

| Work Tube | Holds samples and isolates from elements | Quartz (up to 1200°C), Alumina (up to 1800°C) |

| Atmosphere Control | Manages gas or vacuum environment | Vacuum pumps, gas flow meters, valves |

| Sealing and Cooling | Maintains atmosphere integrity | Sealing flanges, water chillers |

| Control System | Regulates temperature and pressure | Temperature controllers, vacuum gauges |

Need a customized furnace system for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental requirements—from material selection to system integration. Contact us today to discuss how we can enhance your research efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety