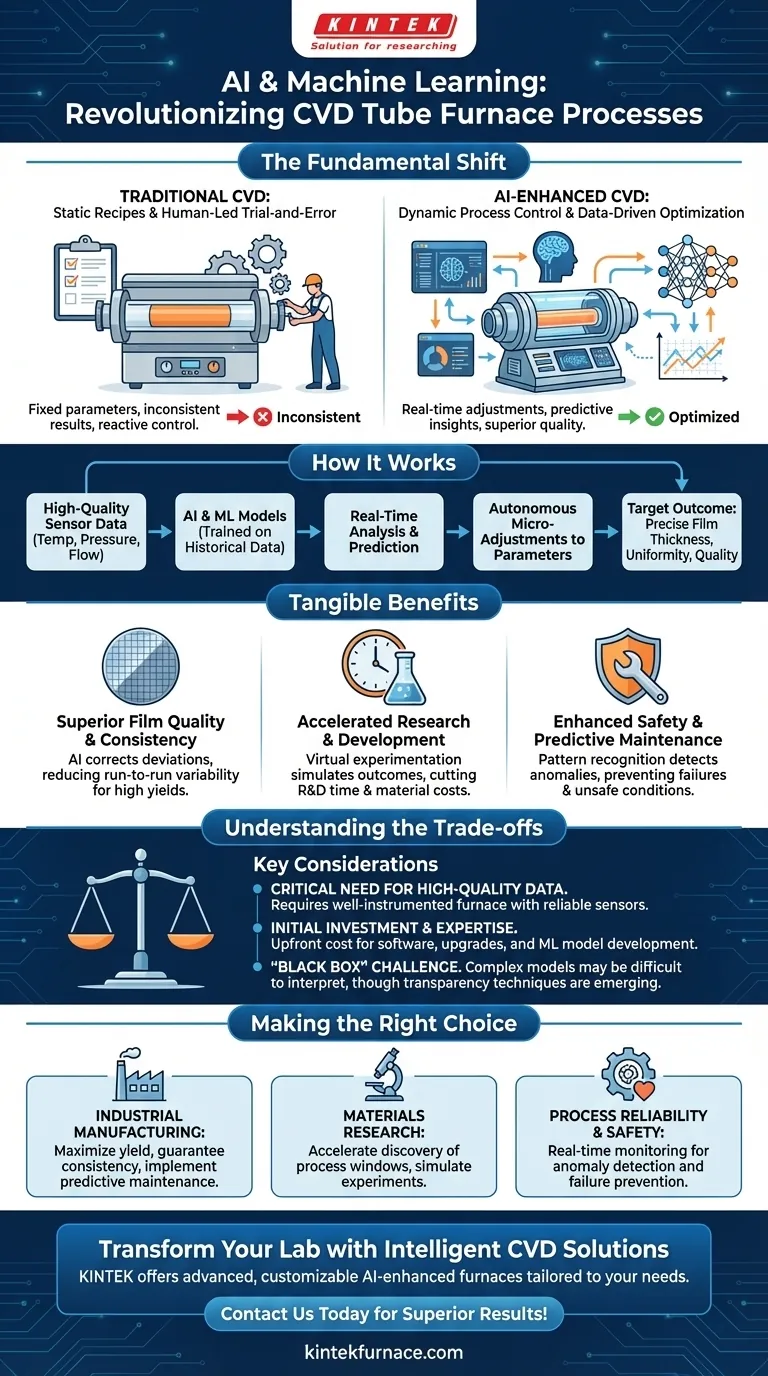

At its core, applying AI and machine learning to CVD tube furnaces transforms the process from one governed by static recipes to one capable of dynamic, real-time optimization. These intelligent algorithms analyze process data to continuously adjust deposition parameters, leading to significant improvements in film quality, higher yields, and a dramatic reduction in process variability from one run to the next.

The fundamental shift is from relying on human-led, trial-and-error experimentation to leveraging data-driven, predictive control. AI doesn't just automate the furnace; it turns it into an intelligent system that can anticipate outcomes and correct its own course.

From Static Recipes to Dynamic Process Control

Traditional CVD processes rely on fixed recipes developed through extensive, time-consuming experimentation. Even minor variations in equipment or materials can lead to inconsistent results. AI fundamentally changes this paradigm.

The Challenge of Traditional CVD

In a conventional setup, operators program setpoints for temperature, pressure, and gas flow rates. The system follows these instructions without adapting to real-world conditions within the tube.

This method is highly dependent on operator skill and the initial calibration of the system. It offers no way to correct for subtle drifts or unexpected events during the deposition process itself.

How AI Enables Real-Time Optimization

AI and ML models are trained on historical data from countless deposition runs. This data includes the input parameters (temperature, pressure, gas flows) and the resulting outputs (film thickness, uniformity, quality).

The model learns the complex, non-linear relationships between these variables. It can then use live sensor data during a run to predict the final outcome and make micro-adjustments to parameters in real time to ensure the result matches the desired target.

Intelligent Operation and Monitoring

Modern tube furnaces feature advanced control systems and a suite of sensors. These systems provide the high-quality data stream that AI algorithms require to function.

This integration supports intelligent, autonomous operation and enables remote monitoring, which simplifies the process for operators and supports continuous, reliable production for industrial applications.

The Tangible Benefits of an AI-Enhanced Furnace

Integrating AI is not just a theoretical improvement; it delivers measurable advantages in quality, speed, and safety.

Superior Film Quality and Consistency

By constantly correcting for deviations, AI ensures that deposition conditions remain optimal throughout the entire process. This leads to superior film uniformity, purity, and structural integrity.

Most importantly, it dramatically reduces run-to-run variability, a critical factor for achieving high yields in any manufacturing or research setting.

Accelerated Research and Development

Instead of running hundreds of physical experiments, researchers can use AI models to simulate the outcomes of different parameter combinations.

This "virtual experimentation" allows for the rapid identification of promising new materials and process windows, drastically cutting down on R&D time and material costs.

Enhanced Safety and Predictive Maintenance

AI models excel at pattern recognition. By continuously analyzing sensor data from heating elements, vacuum pumps, and gas lines, the system can detect subtle anomalies that precede an equipment failure or an unsafe condition.

This allows for predictive maintenance alerts, reducing unplanned downtime and preventing safety incidents before they occur.

Understanding the Trade-offs

While powerful, integrating AI is not a simple plug-and-play solution. It requires a clear understanding of the necessary inputs and potential challenges.

The Critical Need for High-Quality Data

An AI model is only as good as the data it is trained on. To be effective, the CVD furnace must be well-instrumented with accurate and reliable sensors. Without a clean, consistent stream of data, the AI cannot make effective decisions.

Initial Investment and Expertise

Implementing an AI control layer requires an upfront investment in software, potential sensor upgrades, and the expertise to develop and validate the ML models. This initial effort is necessary to unlock the long-term benefits.

The "Black Box" Challenge

Some complex ML models can be difficult to interpret, making it hard to understand precisely why the AI made a specific decision. While this is a known challenge, techniques are emerging to improve model transparency, which is crucial for scientific validation and process debugging.

Making the Right Choice for Your Goal

The way you leverage AI should align directly with your primary objective.

- If your primary focus is industrial manufacturing: Use AI to maximize yield, guarantee run-to-run consistency, and implement predictive maintenance to reduce costly downtime.

- If your primary focus is materials research: Employ ML models to accelerate the discovery of new process windows and simulate experiments, reducing the time from hypothesis to discovery.

- If your primary focus is process reliability and safety: Leverage AI for real-time system health monitoring to detect anomalies and flag potential equipment failures or unsafe conditions before they escalate.

Ultimately, integrating AI elevates a CVD tube furnace from a manually operated tool to an intelligent, data-driven partner in materials innovation and production.

Summary Table:

| Benefit | Description |

|---|---|

| Superior Film Quality | AI ensures uniform, high-purity films with reduced variability for consistent results. |

| Accelerated R&D | ML enables virtual experimentation, cutting down on time and costs for new material discovery. |

| Enhanced Safety | Real-time anomaly detection prevents equipment failures and unsafe conditions. |

| Predictive Maintenance | AI monitors system health to reduce unplanned downtime and improve reliability. |

Ready to transform your lab with intelligent CVD solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're in industrial manufacturing, materials research, or focused on process reliability, our AI-enhanced furnaces can boost your efficiency and outcomes. Contact us today to learn how we can partner with you for superior results!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films

- What are the key features of CVD tube-furnace systems? Unlock Precise Thin-Film Deposition

- How does the gas control system in a CVD tube furnace enhance its functionality? Achieve Precise Thin Film Deposition

- How does a CVD tube furnace achieve high purity in gate media preparation? Master Precision Control for Flawless Films

- What customization options are available for CVD tube furnaces? Tailor Your System for Superior Material Synthesis