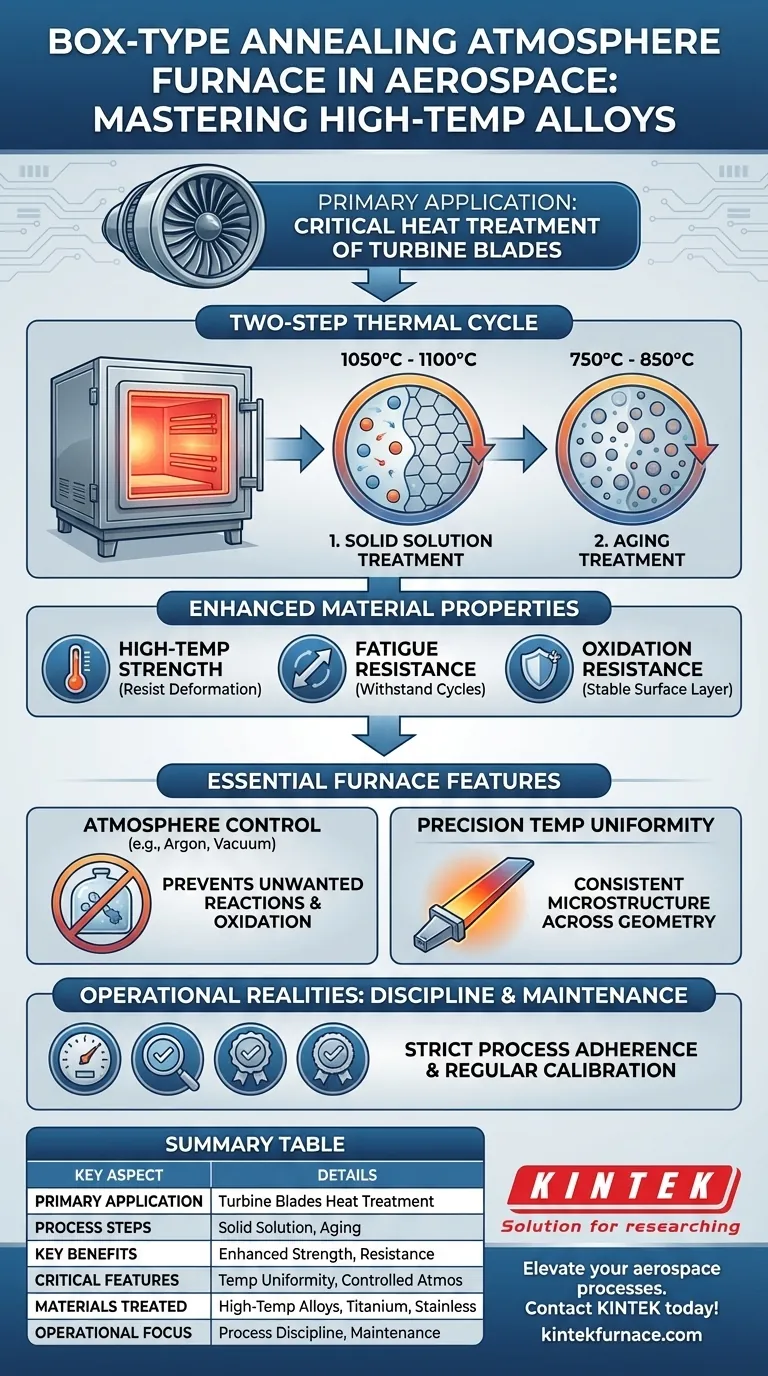

In the aerospace field, a box-type annealing atmosphere furnace is primarily used for the critical heat treatment of high-temperature alloy components, most notably the turbine blades found within aircraft engines. This process involves a precise, two-stage thermal cycle of solid solution and aging treatments to develop the extreme material properties required for safe and reliable engine operation.

The furnace's essential value lies in its dual ability to maintain exceptionally uniform temperatures and a strictly controlled atmosphere. This precise control is non-negotiable for creating the specific microstructural characteristics that allow critical aerospace parts to withstand immense heat, pressure, and stress without failure.

The Core Aerospace Application: Engine Turbine Blades

At the heart of a jet engine, turbine blades operate in one of the most hostile man-made environments. Understanding this context reveals why their manufacturing process is so demanding.

Why Turbine Blades Need Specialized Treatment

Turbine blades spin at thousands of RPM while being subjected to temperatures that can exceed the melting point of many metals. They must resist deformation (creep), fatigue from cyclical stress, and high-temperature oxidation for thousands of hours.

Without specialized heat treatment, the raw high-temperature alloy would fail catastrophically under these high-temperature, high-pressure, and high-speed conditions.

The Two-Step Heat Treatment Process

To build this resilience, the blades undergo a precise thermal process inside the atmosphere furnace.

First is the solid solution treatment, where blades are heated to between 1050°C and 1100°C. At this temperature, strengthening elements within the alloy dissolve into a uniform solid solution, similar to how sugar dissolves in hot water.

Next is the aging treatment, a prolonged soak at a lower temperature, typically between 750°C and 850°C. This step causes the dissolved elements to precipitate out as microscopic, ordered particles within the alloy's grain structure, which act as barriers to dislocation movement and dramatically increase the material's strength.

The Result: Enhanced Material Properties

This carefully controlled process directly enhances the blades' most critical properties:

- High-Temperature Strength: The ability to resist deformation under load at extreme temperatures.

- Fatigue Resistance: The capacity to withstand repeated cycles of stress without cracking.

- Oxidation Resistance: The formation of a stable, protective surface layer that prevents the material from degrading in the hot gas stream.

Why This Furnace is Essential for the Process

Any furnace can get hot, but aerospace applications demand a level of control that only specialized equipment like a box-type atmosphere furnace can provide. Its key features are not just beneficial; they are fundamental requirements.

The Critical Role of Atmosphere Control

Heating reactive metals like high-temperature alloys or titanium alloys in the open air would cause immediate and severe oxidation, compromising the material's integrity.

The furnace's sealed chamber allows for the use of a controlled atmosphere—often an inert gas like argon or a vacuum. This prevents unwanted chemical reactions on the component's surface, ensuring the final material is pure and its properties are uncompromised.

Precision Temperature Uniformity

A complex shape like a turbine blade must be heated evenly across its entire geometry. Even small temperature variations can lead to inconsistent microstructures, creating weak spots that could become failure points in service.

These furnaces are engineered for excellent temperature uniformity, ensuring that every part of the component receives the exact same thermal treatment.

Applications Beyond Turbine Blades

While turbine blades are a primary example, these furnaces are also used for other critical aerospace processes. This includes the annealing or brazing of materials like titanium alloys and stainless steel, where precise temperature and atmosphere control are equally vital for achieving the desired mechanical properties and joint integrity.

Understanding the Operational Realities

The advanced capabilities of these furnaces come with strict operational requirements. In aerospace, there is no margin for error, and the process is just as critical as the equipment.

The Importance of Process Discipline

Modern furnaces feature user-friendly interfaces for setting and monitoring parameters. However, this ease of use is coupled with the need for extreme discipline. The success of the heat treatment depends on exact adherence to validated thermal profiles and atmosphere compositions.

Maintenance is Non-Negotiable

To guarantee precision and reliability, a rigorous maintenance schedule is essential. This is not optional.

- Regular calibration of the temperature control system ensures accuracy.

- Inspection of heating elements prevents unexpected failures and temperature deviations.

- Maintenance of the atmosphere control system and door seals is critical to prevent leaks that could ruin a multi-million dollar batch of components.

Safety and Reliability by Design

These furnaces are equipped with multiple safety interlocks for overcurrent, overvoltage, and overheating protection. A reliable door seal is equally a safety feature—preventing atmosphere leakage—and a quality assurance feature that protects the high-value components inside.

Making the Right Choice for Your Goal

The use of this technology is driven by uncompromising goals. Understanding these goals clarifies the importance of each feature.

- If your primary focus is achieving maximum material strength and durability: The two-step solution and aging process at precisely controlled temperatures is the most critical factor.

- If your primary focus is ensuring material purity and integrity: Strict atmosphere control to prevent oxidation and surface contamination is non-negotiable.

- If your primary focus is maintaining process consistency and repeatability: A rigorous program of furnace calibration, maintenance, and operational discipline is essential.

Ultimately, the box-type annealing atmosphere furnace is more than a piece of equipment; it is a fundamental enabler of modern aerospace engineering.

Summary Table:

| Key Aspect | Details |

|---|---|

| Primary Application | Heat treatment of turbine blades in aircraft engines |

| Process Steps | Solid solution treatment (1050-1100°C), Aging treatment (750-850°C) |

| Key Benefits | Enhanced high-temperature strength, fatigue resistance, oxidation resistance |

| Critical Features | Precise temperature uniformity, controlled atmosphere (e.g., argon or vacuum) |

| Materials Treated | High-temperature alloys, titanium alloys, stainless steel |

| Operational Focus | Strict process discipline, regular maintenance, safety interlocks |

Elevate your aerospace heat treatment processes with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for unique experimental needs, such as turbine blade treatments. Contact us today to discuss how we can enhance your material properties and operational reliability!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment