In the dental laboratory, lithium disilicate is primarily processed using a specialized heat-press technique. This method involves melting a pre-fabricated ingot of the glass-ceramic material in a furnace and then pressing the molten material into a mold created using a traditional lost-wax technique. This ensures the final restoration accurately captures the desired shape while developing its signature strength and esthetic properties.

The heat-pressing process is not merely a way to shape lithium disilicate; it is a controlled thermal treatment designed to preserve the material's precise crystalline structure, which is the source of its unique combination of strength and optical translucency.

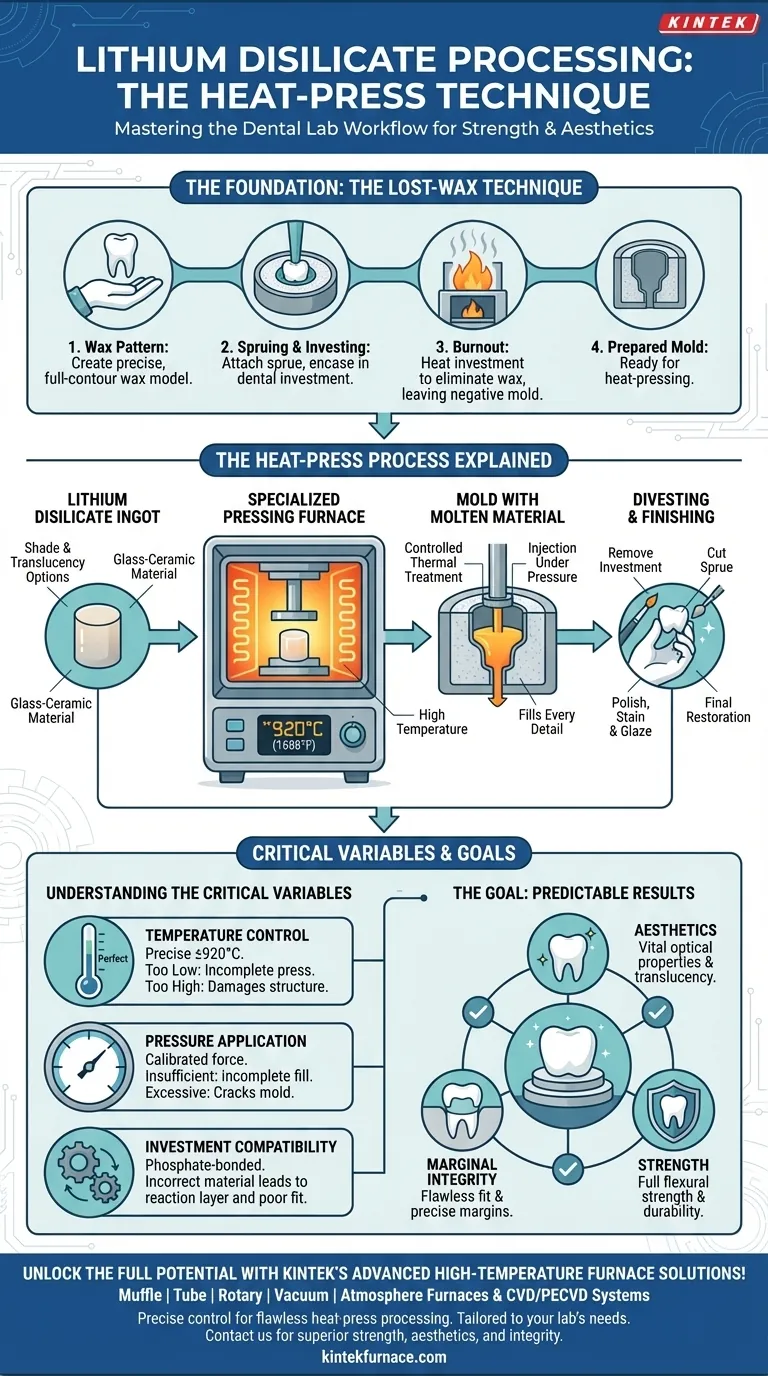

The Foundation: The Lost-Wax Technique

The entire pressing process is built upon the lost-wax technique, a method that has been trusted for centuries in fields from jewelry making to metal casting. It allows for the creation of a highly detailed, one-to-one negative mold of the final restoration.

Step 1: The Wax Pattern

A technician first creates a precise, full-contour model of the final crown, veneer, or inlay using a special dental wax. This "wax-up" is a physical representation of the desired outcome and must be perfect in its anatomy, margins, and contacts.

Step 2: Spruing and Investing

A wax channel, called a sprue, is attached to the wax pattern. The entire assembly is then placed inside a metal ring and encased in a plaster-like material known as dental investment. Once the investment hardens, the ring is placed in a furnace to burn out the wax, leaving a void—a perfect negative mold—of the restoration and the sprue channel.

The Heat-Press Process Explained

With the negative mold prepared, the specific processing of the lithium disilicate can begin. This is where specialized equipment and precise control are essential to success.

The Lithium Disilicate Ingot

The raw material is a small, pre-crystallized cylinder of lithium disilicate glass-ceramic called an ingot. These ingots are manufactured in a variety of shades and translucency levels (e.g., High Translucency, Low Translucency) to match different clinical needs.

The Pressing Furnace

The investment mold and the chosen lithium disilicate ingot are placed into a specialized pressing furnace. This device heats both components to a specific, high temperature—typically around 920°C (1688°F). At this temperature, the ingot softens to a viscous, pressable consistency.

Injection Under Pressure

Once the material reaches the correct viscosity, a ceramic or alumina plunger within the furnace applies pressure. This forces the molten glass-ceramic out of the ingot, down the sprue channel, and into every fine detail of the negative mold.

Divesting and Finishing

After a controlled cooling cycle, the investment ring is removed from the furnace. The technician carefully breaks away the investment material—a process called divesting—to reveal the pressed ceramic restoration. The sprue is cut off, and the restoration is finished and polished. Often, it undergoes a final staining and glazing cycle in a separate porcelain furnace to add surface characterization and a lifelike luster.

Understanding the Critical Variables

The success of a pressed lithium disilicate restoration is not automatic. It depends entirely on the meticulous control of key variables, where slight deviations can compromise the final result.

Why Temperature Control is Paramount

The reference to "accurate temperature control" is critical. If the furnace temperature is too low, the ingot will not flow properly, resulting in an incomplete press and open margins. If the temperature is too high, it can damage the crystalline microstructure of the material, degrading its strength and negatively impacting its optical properties and shade.

The Importance of Pressure

The pressure applied by the plunger must be calibrated correctly. Insufficient pressure leads to an incomplete fill of the mold, similar to low temperature. Excessive pressure can introduce stress into the ceramic or even crack the investment mold, leading to an inaccurate and distorted restoration.

Investment Material Compatibility

The investment material must be chemically compatible with lithium disilicate and phosphate-bonded to withstand the high pressing temperatures without degrading. An incorrect investment can react with the ceramic surface, creating a reaction layer that is difficult to remove and compromises the restoration's fit.

The Goal: Predictable Aesthetics and Strength

Adhering to a strict processing protocol is how a laboratory translates the inherent potential of lithium disilicate into a clinically successful restoration.

- If your primary focus is maximum esthetics: Selecting the correct ingot translucency and ensuring precise temperature control are essential to preserving the material's vital optical properties.

- If your primary focus is marginal integrity: A flawless wax pattern and a fully controlled press are non-negotiable to ensure the molten ceramic fills the entire mold for a perfect fit.

- If your primary focus is clinical strength: Proper processing according to manufacturer specifications is the only way to ensure the material develops its full flexural strength for long-term durability.

Mastering this technique-sensitive process is fundamental to unlocking the full clinical potential of this exceptional dental material.

Summary Table:

| Process Step | Key Details | Critical Variables |

|---|---|---|

| Lost-Wax Technique | Create wax pattern, sprue, and investment mold for precise shape | Accuracy of wax pattern and investment compatibility |

| Heat-Press Process | Melt ingot at ~920°C, inject into mold under pressure | Temperature control, pressure calibration, material flow |

| Finishing | Divest, cut sprue, polish, and glaze for final aesthetics | Careful handling to avoid damage and ensure surface quality |

Unlock the full potential of lithium disilicate in your dental lab with KINTEK's advanced high-temperature furnace solutions! Our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems are engineered for precise temperature control and reliable performance, ensuring flawless heat-press processing. With deep customization capabilities, we tailor our equipment to meet your unique experimental and production needs, helping you achieve superior strength, aesthetics, and marginal integrity in every restoration. Contact us today to discuss how we can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations