In a Chemical Vapor Deposition (CVD) system, gas delivery is managed by a highly integrated network of hardware and software designed for extreme precision. This involves header valves with pneumatic actuators controlling the raw material supply, which is then routed through custom piping and managed by specialized precursor delivery modules. This entire physical system is orchestrated by an advanced, programmable control unit to ensure the exact flow, mixing, and timing required for the deposition process.

The core principle to understand is that gas delivery in CVD is not merely about transport; it is about precisely controlling a molecular recipe in real time. The flow rate and mixing ratio of precursor gases directly dictate the composition, uniformity, and fundamental properties of the final thin film.

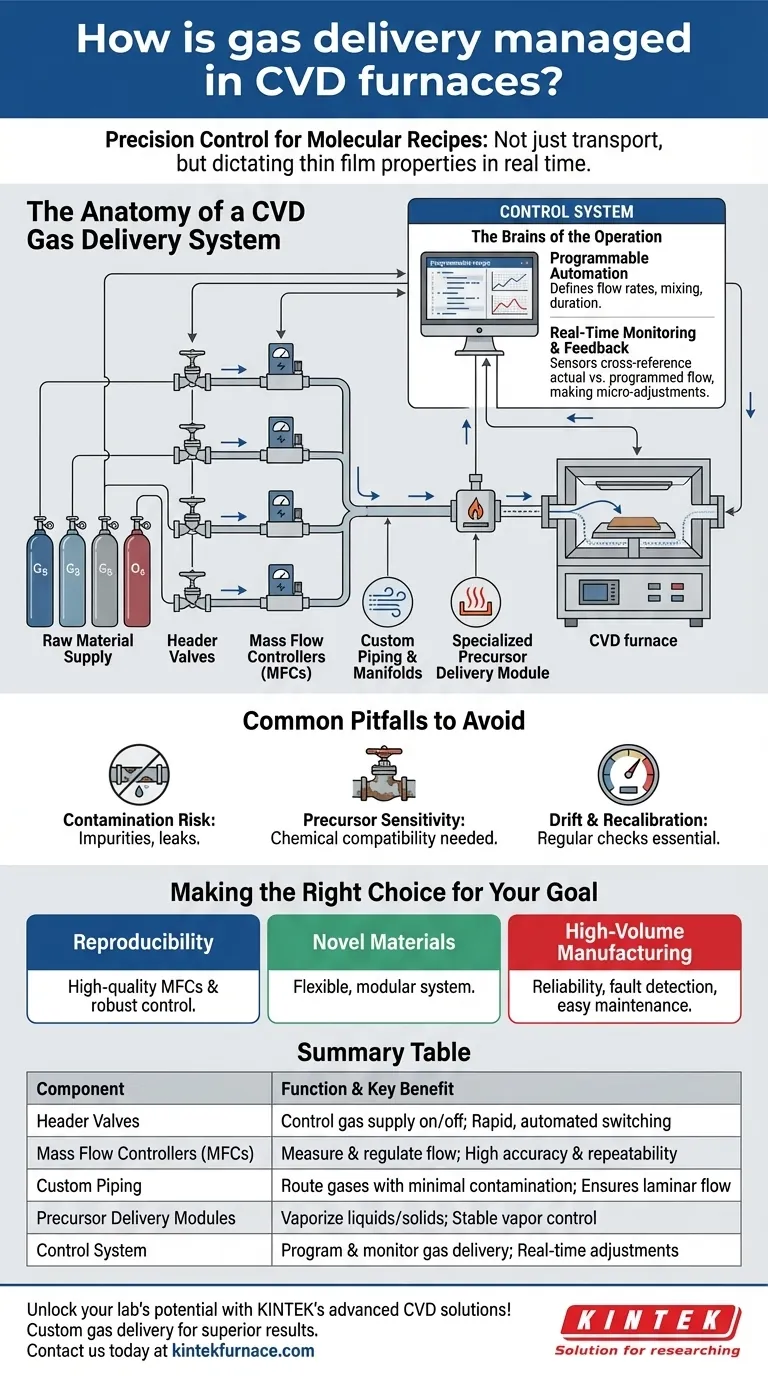

The Anatomy of a CVD Gas Delivery System

To achieve atom-by-atom control, a CVD furnace relies on a series of specialized components working in perfect concert. Each part has a specific role in transforming bulk raw materials into a precisely controlled reactive gas phase inside the chamber.

Raw Material Supply and Header Valves

The process begins at the source gas cylinders. Header valves, often operated by pneumatic actuators, serve as the primary on/off gates for these raw materials. Pneumatic control allows for rapid, automated, and reliable switching, which is the first step in executing a programmed deposition recipe.

Mass Flow Controllers (MFCs)

The heart of gas delivery precision is the Mass Flow Controller (MFC). After the header valve, each gas line runs through an MFC, which measures and controls the volume of gas passing through it with incredible accuracy. This allows the system to meter out the exact amount of each precursor gas required, forming the basis for a repeatable process.

Custom Piping and Manifolds

The piping that connects the gas sources to the furnace chamber is not standard plumbing. It is custom-designed to prevent contamination and ensure predictable gas behavior. Key goals are to minimize "dead space" where old gases can linger and to maintain laminar flow, preventing turbulence that could disrupt uniform deposition.

Specialized Precursor Delivery

Not all precursors are simple gases at room temperature; many are liquids or even solids. These require specialized precursor delivery modules that gently heat the material to turn it into a vapor. The system then introduces this vapor into the gas stream at a stable, controlled rate, just like any other process gas.

The Brains of the Operation: The Control System

The physical hardware is only effective when guided by a sophisticated control system. This is where recipes are programmed, monitored, and executed, ensuring the process is both precise and repeatable.

Programmable Automation

Modern CVD furnaces operate on programmable recipes. An engineer defines every step of the process—which gases to use, their flow rates, the duration, and the mixing ratios. The control system then executes this sequence flawlessly, removing the potential for human error.

Real-Time Monitoring and Feedback

The control system isn't just executing commands blindly. It uses sensors to monitor the system in real time, cross-referencing actual flow rates and pressures against the programmed recipe. This feedback loop allows the system to make micro-adjustments on the fly, compensating for any minor fluctuations to ensure consistency from one run to the next.

The Goal: Controlling the Reaction Gas Phase

Ultimately, the entire gas delivery apparatus works toward one goal: creating a perfectly defined reaction gas phase inside the vacuum chamber. By controlling the composition of this gas mixture, you directly influence how the precursor molecules decompose and react on the substrate surface, which is the very essence of thin-film deposition.

Common Pitfalls to Avoid

The precision of a CVD gas delivery system is also its primary vulnerability. A failure to manage its complexity can lead to failed processes and inconsistent results.

Contamination Risk

The system is highly sensitive to impurities. A small leak introducing air into a gas line or residual contamination from a previous run can completely alter the film's chemistry and ruin the product. Meticulous cleaning and leak-checking are non-negotiable.

Precursor Sensitivity and Material Compatibility

Different precursor chemicals have unique properties. Some are highly corrosive, while others are unstable at certain temperatures. The gas delivery lines, valves, and seals must be made of materials that are fully compatible with the specific chemicals being used to prevent degradation and contamination.

Drift and Recalibration

Over time, the sensors and controllers within MFCs can "drift," becoming less accurate. Without a regular calibration schedule, your system might report a specific flow rate while delivering a different one, leading to a gradual and often mysterious decline in film quality and reproducibility.

Making the Right Choice for Your Goal

Your approach to managing and specifying a gas delivery system should align directly with your desired outcome.

- If your primary focus is process reproducibility: Invest in high-quality Mass Flow Controllers and a robust, automated control system with real-time feedback to guarantee run-to-run consistency.

- If your primary focus is developing novel materials: Prioritize a flexible, modular system with easily swappable gas lines and support for multiple types of liquid or solid precursor delivery modules.

- If your primary focus is high-volume manufacturing: Emphasize system reliability, real-time monitoring with automated fault detection, and streamlined maintenance procedures to maximize uptime and yield.

Ultimately, mastering gas delivery is mastering the very chemistry that defines your final product.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Header Valves | Control gas supply on/off | Rapid, automated switching |

| Mass Flow Controllers (MFCs) | Measure and regulate gas flow | High accuracy and repeatability |

| Custom Piping | Route gases with minimal contamination | Ensures laminar flow and uniformity |

| Precursor Delivery Modules | Vaporize liquids/solids for introduction | Stable vapor control for diverse precursors |

| Control System | Program and monitor gas delivery | Real-time adjustments and error reduction |

Unlock the full potential of your lab with KINTEK's advanced CVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Tube, Vacuum & Atmosphere, and CVD/PECVD Systems tailored to your needs. Our deep customization capabilities ensure precise gas delivery management for superior thin film results. Ready to enhance your process? Contact us today to discuss how we can support your research or production goals!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition