In aerospace manufacturing, furnace brazing is a cornerstone technology used to join high-performance materials for the most demanding applications. It is the go-to method for creating strong, lightweight, and heat-resistant components like jet engine parts, heat exchangers, and critical structural assemblies from advanced titanium alloys and nickel-based superalloys.

Furnace brazing is more than a simple joining technique; it is a highly controlled thermal process that protects the metallurgical integrity of advanced alloys, enabling the creation of complex, high-performance components that are fundamental to modern aircraft safety and efficiency.

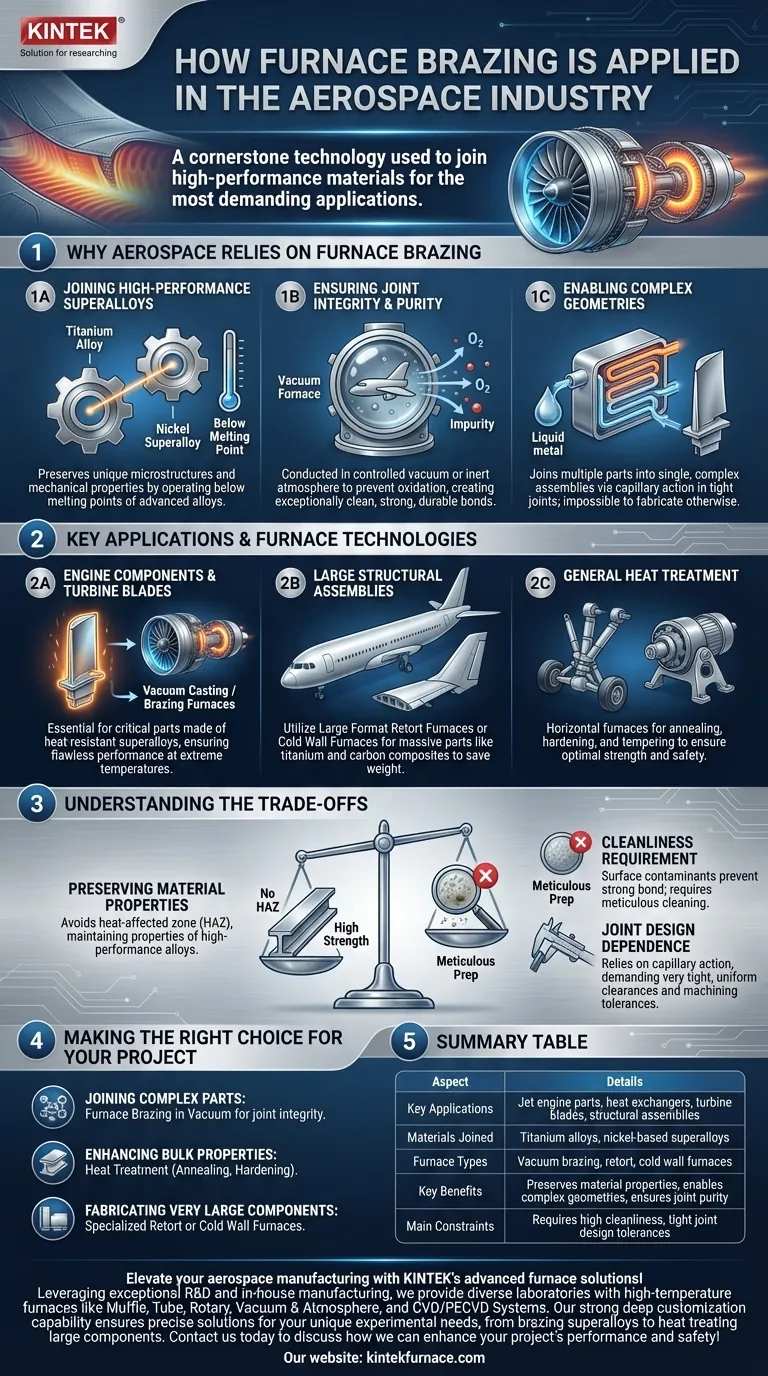

Why Aerospace Relies on Furnace Brazing

Furnace brazing solves a fundamental challenge in aerospace: how to join advanced materials without compromising their carefully engineered properties. The process is conducted in a controlled environment, which is critical for the exotic alloys used in the industry.

Joining High-Performance Superalloys

The aerospace industry depends on materials like titanium alloys and nickel-based superalloys for their incredible strength-to-weight ratio and resistance to extreme temperatures.

Furnace brazing is exceptionally well-suited for these materials because the process occurs below their melting point, preserving their unique microstructures and mechanical properties.

Ensuring Joint Integrity and Purity

Components in jet engines and high-altitude aircraft are exposed to immense stress and oxidative environments. A weak or contaminated joint is a catastrophic point of failure.

By performing the brazing inside a vacuum furnace or a furnace with a controlled inert atmosphere, the process prevents oxidation. This results in an exceptionally clean, strong, and durable bond that can withstand the harshest conditions.

Enabling Complex Geometries

Many aerospace components, such as heat exchangers and turbine blades, feature intricate internal channels and complex shapes that are impossible to fabricate as a single piece.

Furnace brazing allows engineers to join multiple, simpler machined parts into a single, complex assembly. The filler metal flows via capillary action into tight-fitting joints, creating a monolithic final component that is both strong and leak-proof.

Key Applications and Furnace Technologies

Different aerospace components require specific types of furnaces and processes to meet their unique demands for scale, material, and performance.

Engine Components and Turbine Blades

Critical engine parts, especially turbine blades, are made from heat-resistant superalloys that must perform flawlessly at extreme temperatures.

Vacuum casting furnaces and vacuum brazing furnaces are essential for producing and assembling these parts, ensuring the material properties are perfectly maintained without introducing impurities.

Large Structural Assemblies

Modern aircraft incorporate very large components made from titanium and even carbon composites to save weight and increase strength.

For these parts, manufacturers use large format retort furnaces. For even bigger components, a cold wall furnace may be used to avoid the cost and limitations of an enormous retort, allowing for the processing of massive aircraft parts.

General Heat Treatment

Beyond joining, furnaces are critical for the general heat treatment of aerospace alloys. Processes like annealing, hardening, and tempering are performed in horizontal furnaces to ensure landing gear, engine mounts, and other parts have the optimal strength and durability required by stringent safety standards.

Understanding the Trade-offs

While furnace brazing is powerful, it is not a universal solution. Understanding its limitations is key to applying it correctly.

Benefit: Preserving Material Properties

The single greatest advantage of brazing over welding is temperature. By operating below the base metal's melting point, brazing avoids the heat-affected zone (HAZ) common in welding, which can degrade the properties of high-performance alloys.

Constraint: Requirement for Cleanliness

Furnace brazing is extremely sensitive to contaminants. The surfaces to be joined must be meticulously cleaned and prepared. Any oils, oxides, or dirt will prevent the filler metal from wetting the surface and creating a strong bond.

Constraint: Dependence on Joint Design

The process relies entirely on capillary action to draw the molten filler metal into the joint. This requires very tight, uniform clearances between the parts being joined, which places a significant constraint on component design and machining tolerances.

Making the Right Choice for Your Project

Selecting the correct thermal process is not just a manufacturing detail; it is fundamental to the final component's performance and safety.

- If your primary focus is joining complex superalloy parts: Furnace brazing in a controlled vacuum atmosphere is the definitive method to ensure joint integrity without damaging the base material.

- If your primary focus is enhancing bulk material properties: Heat treatment processes like annealing, hardening, and tempering are the necessary steps to achieve target strength and durability.

- If your primary focus is fabricating very large components: You must use specialized equipment like large format retort or cold wall furnaces, whether for brazing or heat treatment.

Ultimately, mastering these advanced thermal processes is essential for building aircraft that are lighter, faster, and safer.

Summary Table:

| Aspect | Details |

|---|---|

| Key Applications | Jet engine parts, heat exchangers, turbine blades, structural assemblies |

| Materials Joined | Titanium alloys, nickel-based superalloys |

| Furnace Types | Vacuum brazing furnaces, retort furnaces, cold wall furnaces |

| Key Benefits | Preserves material properties, enables complex geometries, ensures joint purity |

| Main Constraints | Requires high cleanliness, tight joint design tolerances |

Elevate your aerospace manufacturing with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, from brazing superalloys to heat treating large components. Contact us today to discuss how we can enhance your project's performance and safety!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems