In the aerospace industry, Chemical Vapor Deposition (CVD) is primarily used to apply highly durable, protective coatings onto critical components, especially those within the hot sections of jet engines. These engineered thin films serve as a shield against extreme temperatures, oxidation, and corrosion, which directly enhances the performance, safety, and operational lifespan of the aircraft.

The core challenge in aerospace propulsion is managing extreme environments. CVD is not just a manufacturing step; it is a critical enabling technology that allows engine components to survive conditions that would otherwise cause them to rapidly degrade and fail.

Why Aerospace Demands Advanced Coatings

The environment inside a modern jet engine is one of the most hostile imaginable. Components like turbine blades and vanes are subjected to immense physical stress, temperatures that can exceed the melting point of their base metal alloys, and a constant barrage of corrosive high-velocity gases.

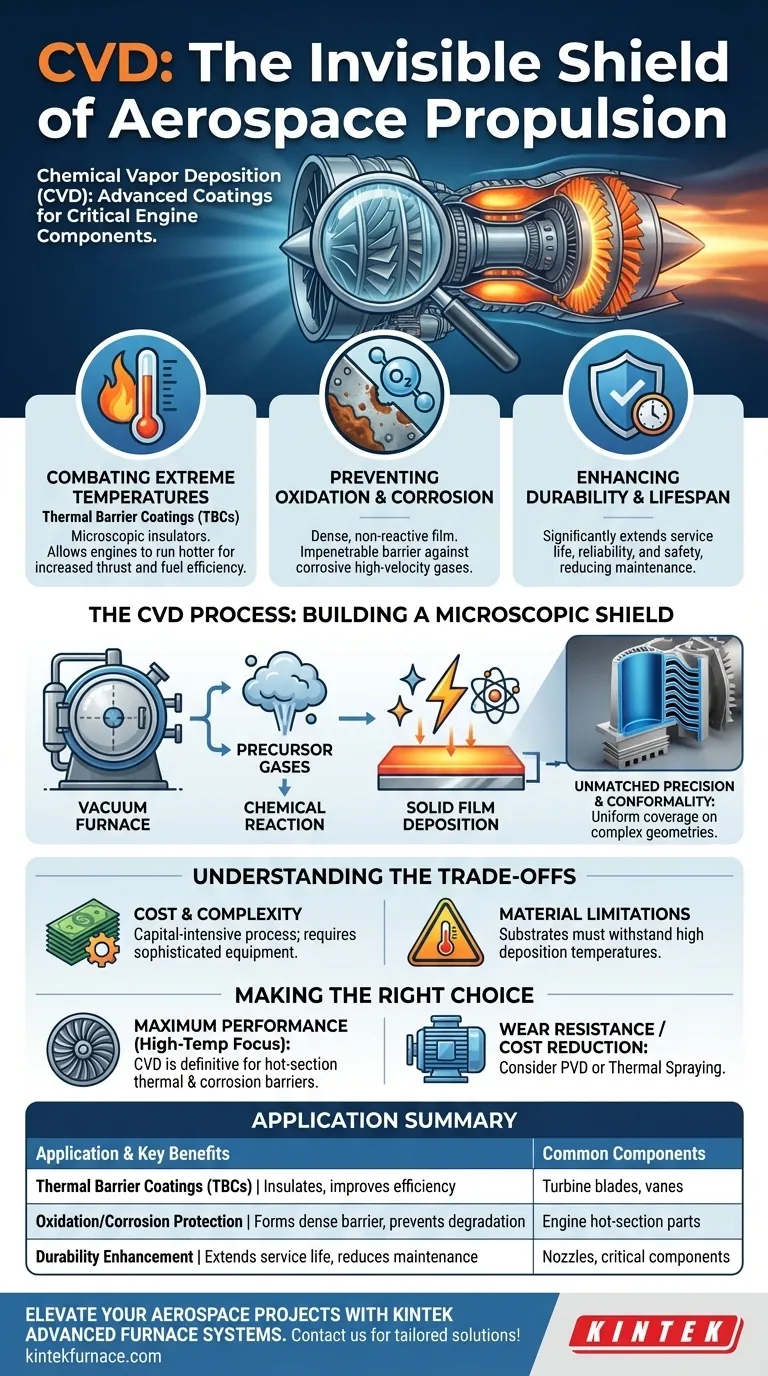

Combating Extreme Temperatures

CVD is used to create Thermal Barrier Coatings (TBCs). These are thin layers of ceramic material that exhibit very low thermal conductivity.

This coating acts as a microscopic insulator, keeping the underlying superalloy component at a manageable temperature even as the surface is exposed to extreme heat. This allows engines to run hotter, which increases thrust and fuel efficiency.

Preventing Oxidation and Corrosion

At high temperatures, oxygen and other elements in the hot gas stream aggressively attack metal surfaces, a process known as high-temperature corrosion and oxidation.

CVD deposits a dense, non-reactive film that forms an impenetrable barrier between the superalloy and these corrosive gases. This protection is essential for preventing the component from literally being eaten away during operation.

Enhancing Durability and Component Lifespan

By shielding components from both thermal and chemical attack, CVD coatings dramatically extend their service life. This translates to longer intervals between engine overhauls, lower maintenance costs, and a significant increase in overall reliability and safety.

The CVD Process: Building a Microscopic Shield

Understanding how these coatings are applied reveals why the process is so effective for the complex geometries found in aerospace parts.

From Gas to Solid

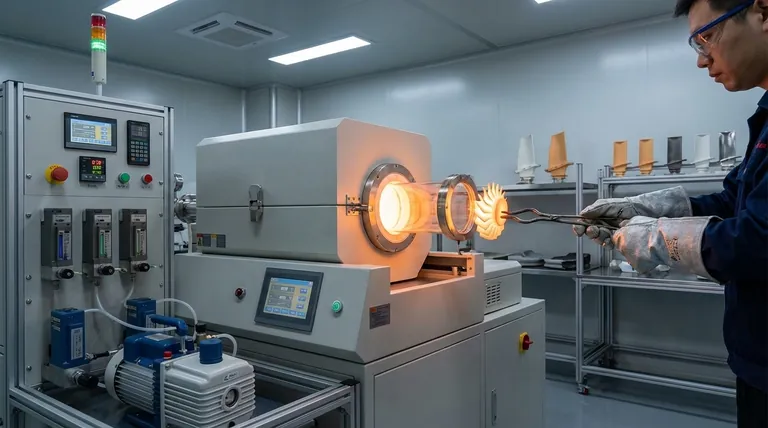

In simple terms, CVD is like painting with a vapor. The component to be coated is placed inside a sealed, high-temperature vacuum furnace.

Specific precursor gases are then introduced into the chamber. When these gases come into contact with the hot surface of the component, they react and decompose, leaving behind a thin, solid film of the desired material.

Unmatched Precision and Conformality

A key advantage of CVD is its conformality. Because the coating is built atom by atom from a gas phase, it can uniformly cover highly complex shapes, including the intricate internal cooling channels of a turbine blade.

This ensures complete, seamless protection with no gaps or weak points, a feat that is difficult to achieve with line-of-sight processes like spraying.

Understanding the Trade-offs

While incredibly effective, CVD is a specialized process with specific considerations. It is not a universal solution for all coating needs.

The Cost and Complexity

CVD is a capital-intensive process that requires sophisticated vacuum furnaces, precise gas handling systems, and a highly controlled environment. This makes it more expensive than some alternative coating methods.

Material Limitations

The CVD process itself involves very high temperatures. The component being coated (the substrate) must be able to withstand the deposition temperature without being damaged or losing its own engineered properties.

Distinguishing from Other Industries

While the fundamental process is the same, the application of CVD in aerospace is distinct from its use in electronics or solar. In aerospace, the goal is thermo-structural protection using robust ceramic materials. In electronics, the focus is on creating ultra-pure, electrically active semiconductor layers.

Making the Right Choice for Your Goal

Applying CVD is a strategic decision driven by the specific performance requirements of a component.

- If your primary focus is maximum performance and safety in a high-temperature environment: CVD is the definitive choice for applying thermal and corrosion barriers on critical hot-section components like turbine blades and nozzles.

- If your primary focus is wear resistance on cooler components or cost reduction: Other processes, like Physical Vapor Deposition (PVD) or thermal spraying, may be more suitable and cost-effective alternatives.

Ultimately, CVD is a cornerstone technology that enables engineers to push the boundaries of propulsion and aerospace materials science.

Summary Table:

| Application | Key Benefits | Common Components |

|---|---|---|

| Thermal Barrier Coatings (TBCs) | Insulates against extreme heat, improves fuel efficiency | Turbine blades, vanes |

| Oxidation/Corrosion Protection | Forms dense barrier, prevents material degradation | Engine hot-section parts |

| Durability Enhancement | Extends service life, reduces maintenance costs | Nozzles, other critical components |

Ready to elevate your aerospace or lab projects with advanced high-temperature solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to discuss how our expertise can enhance your component performance and reliability!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What role do CVD tube furnace sintering systems play in 2D material synthesis? Enabling High-Quality Atomic Layer Growth

- What is the working principle of a CVD tube furnace? Achieve Precise Thin Film Deposition for Your Lab

- What makes a CVD Tube Furnace essential for material science and nanotechnology? Unlock Precision in Material Synthesis

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More