At its core, a three-zone furnace is a single heating chamber that is internally divided into three distinct, independently controlled heating sections. Each zone is equipped with its own heating elements, a temperature sensor (typically a thermocouple), and a dedicated controller, allowing for precise thermal management across the length of the chamber.

The purpose of a three-zone structure is not just to have more heaters, but to overcome the primary limitation of single-zone furnaces: heat loss at the ends. This design enables either exceptional temperature uniformity along the chamber or the creation of precise, deliberate temperature gradients.

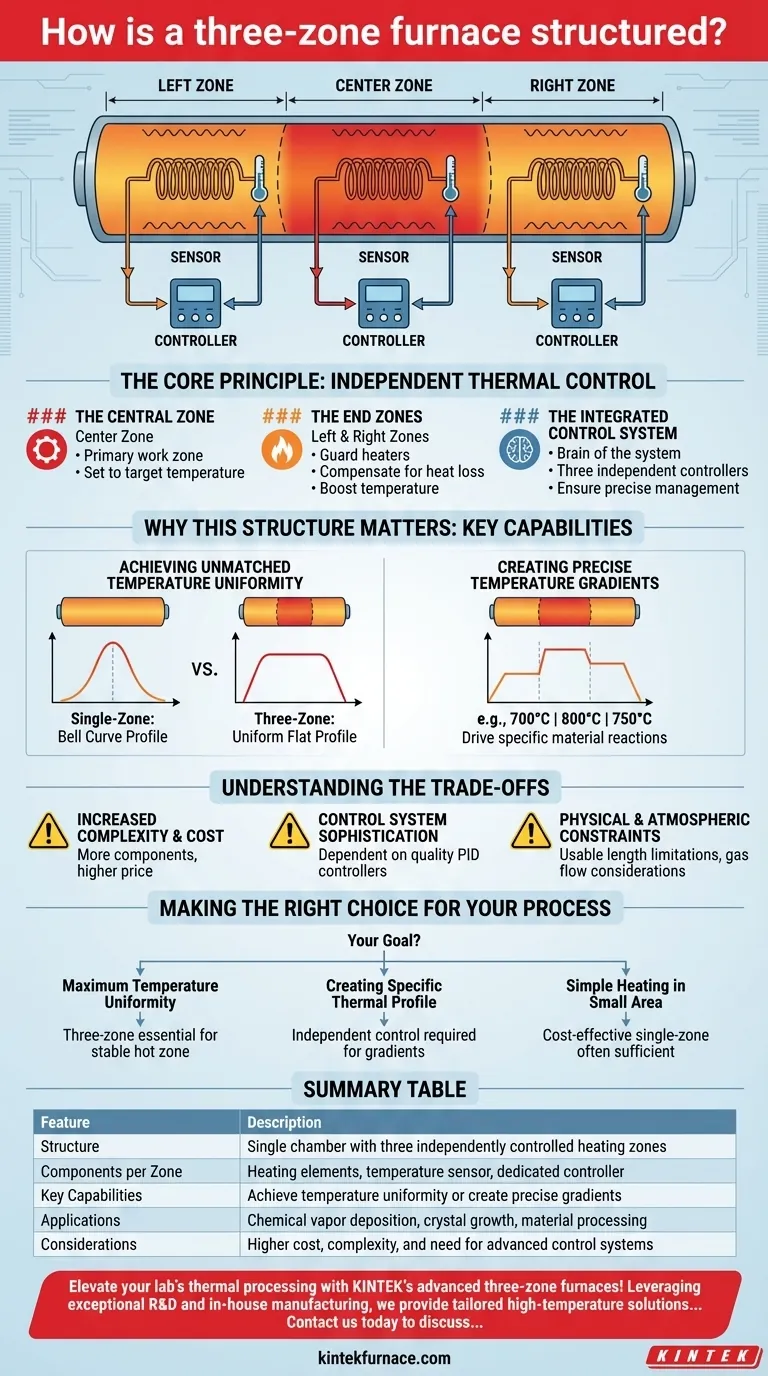

The Core Principle: Independent Thermal Control

A three-zone furnace's power comes from its segmented design. By treating the heating chamber as three separate areas, it can dynamically adjust to create a highly controlled thermal environment.

### The Central Zone

The middle section is the primary work zone. In many applications, this zone is set to the desired target temperature for the material or process being run.

### The End Zones

The two zones at either end of the chamber act as guard heaters. Their main purpose is to compensate for the natural heat loss that occurs at the openings of the furnace. By boosting the temperature in these zones, they prevent the ends from being cooler than the center.

### The Integrated Control System

The system's "brain" is a set of three controllers, one for each zone. Each controller receives a constant signal from its zone's sensor and adjusts the power to its heating elements to maintain the programmed setpoint, ensuring each section operates independently.

Why This Structure Matters: Key Capabilities

The separation of control allows for thermal profiles that are impossible to achieve with a single heating element. This unlocks two primary, and nearly opposite, capabilities.

### Achieving Unmatched Temperature Uniformity

In a single-zone furnace, the temperature profile naturally forms a bell curve, with a hot "sweet spot" in the middle and cooler temperatures at the ends. A three-zone furnace corrects this by allowing the end zones to be set slightly hotter, creating a flat, uniform temperature profile across a much larger portion of the chamber's length.

### Creating Precise Temperature Gradients

For advanced processes like chemical vapor deposition or certain types of crystal growth, a non-uniform temperature profile is required. The three-zone design allows a user to program a specific gradient—for example, setting the zones to 700°C, 800°C, and 750°C—to drive a specific material reaction or physical process.

Understanding the Trade-offs

While powerful, the three-zone design introduces complexities and considerations that are not present in simpler furnaces.

### Increased Complexity and Cost

The design inherently involves more components: three sets of heating elements, sensors, and controllers. This increases the initial purchase price and introduces more potential points of failure compared to a single-zone unit.

### Control System Sophistication

The performance of the furnace is heavily dependent on the quality of its PID controllers and software. Achieving true uniformity requires controllers that can work together intelligently to minimize temperature overshoots and maintain stability.

### Physical and Atmospheric Constraints

The length of each zone and the diameter of the tube are critical design parameters. The usable uniform length is always a fraction of the total heated length. Furthermore, if your process requires a specific atmosphere (such as inert or reducing gas), the system must be designed to accommodate this safely and effectively.

Making the Right Choice for Your Process

Your specific thermal processing goal is the only factor that matters when deciding if a three-zone furnace is necessary.

- If your primary focus is maximum temperature uniformity: A three-zone furnace is essential to create a long, stable hot zone and eliminate the temperature drop-off at the chamber ends.

- If your primary focus is creating a specific thermal profile: The independent zone control is the only way to reliably program and maintain precise temperature gradients along the furnace.

- If your primary focus is simple heating in a small area: A more cost-effective single-zone furnace is often sufficient if your sample is small and can fit within its central uniform region.

Ultimately, understanding this structure empowers you to select the right tool for the precision your work demands.

Summary Table:

| Feature | Description |

|---|---|

| Structure | Single chamber with three independently controlled heating zones |

| Components per Zone | Heating elements, temperature sensor, dedicated controller |

| Key Capabilities | Achieve temperature uniformity or create precise gradients |

| Applications | Chemical vapor deposition, crystal growth, material processing |

| Considerations | Higher cost, complexity, and need for advanced control systems |

Elevate your lab's thermal processing with KINTEK's advanced three-zone furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Contact us today to discuss how our precision furnaces can optimize your processes and drive innovation!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety