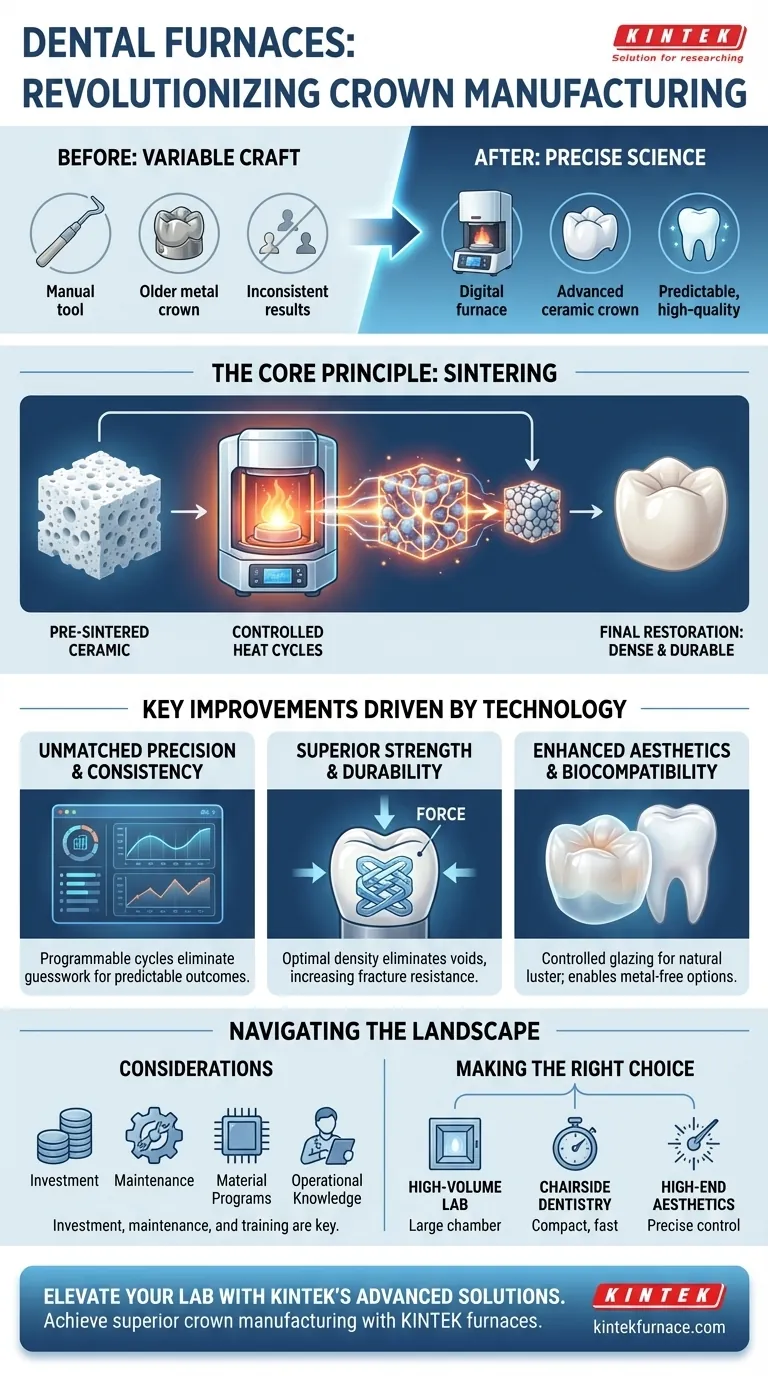

The modern dental furnace is the critical technology that transformed crown manufacturing from a variable craft into a precise science. These devices use highly controlled heat cycles to sinter advanced ceramic materials, resulting in restorations with unprecedented strength, aesthetic quality, and consistency. This leap in technology has made failures less common and has enabled the widespread use of materials like zirconia for durable and lifelike crowns, bridges, and inlays.

The central challenge in restorative dentistry has always been creating crowns that are both strong enough to withstand biting forces and aesthetically pleasing. Dental furnaces solve this by providing the precise, high-temperature environment required to transform pre-fabricated ceramic blocks into dense, durable, and natural-looking final restorations.

How Furnaces Revolutionized the Process

Before the widespread adoption of advanced dental furnaces, the options for durable crowns were often limited to metal or porcelain-fused-to-metal (PFM) restorations. While strong, these often lacked the natural appearance of modern all-ceramic options.

The Core Principle: Sintering

Sintering is the fundamental process at the heart of modern crown fabrication. It involves taking a porous, chalk-like block of milled ceramic and heating it to a specific temperature just below its melting point.

This intense heat causes the individual particles to fuse together, eliminating the pores and dramatically increasing the material's density and strength. Think of it like firing clay in a kiln to create a hard, durable ceramic pot.

Unlocking Advanced Materials

Modern furnaces are essential for working with today's most popular restorative materials, particularly zirconia and lithium disilicate.

These materials are milled in a soft, pre-sintered state, which is easy to shape. However, they only achieve their final, robust properties after undergoing a precise, multi-stage firing cycle that can only be executed by a programmable dental furnace.

Key Improvements Driven by Furnace Technology

The impact of dental furnaces extends beyond simply enabling new materials. They have fundamentally improved the quality and predictability of the final product.

Unmatched Precision and Consistency

Modern furnaces allow technicians to program specific heating rates, hold times, and cooling sequences. This digital control eliminates the guesswork and variability of older methods, ensuring that every crown is sintered under ideal conditions for its specific material.

The result is a highly predictable and consistent outcome for every restoration that leaves the lab.

Superior Strength and Durability

The final strength of a ceramic crown is directly tied to how well it was sintered. By achieving optimal density and eliminating internal voids, furnaces produce restorations that are exceptionally resistant to fracture and wear.

This durability translates to longer-lasting crowns and fewer costly remakes for both the lab and the dental practice.

Enhanced Aesthetics and Biocompatibility

Proper firing cycles are also crucial for aesthetics. Furnaces allow for controlled glazing stages that create a smooth, stain-resistant, and natural-looking surface luster.

Furthermore, by enabling the use of all-ceramic materials like zirconia, furnaces have helped move the industry toward more biocompatible restorations that do not contain metal.

Understanding the Trade-offs

While the benefits are clear, adopting this technology involves practical considerations.

Initial Investment and Maintenance

High-quality dental furnaces represent a significant capital investment for a dental lab or clinic.

They also require routine cleaning and calibration to ensure their temperature accuracy remains consistent over time, which is critical for predictable results.

Material-Specific Programs

A dental furnace is not a "one-size-fits-all" appliance. Different ceramic materials, and even different shades of the same material, require unique firing programs.

Technicians must be knowledgeable about these specific requirements to avoid producing weak or aesthetically flawed restorations.

Operational Knowledge

While highly automated, these machines require trained personnel to operate them correctly. Understanding how to load the furnace, select the right program, and troubleshoot potential issues is essential for any successful digital workflow.

Making the Right Choice for Your Goal

The right furnace depends entirely on the specific needs of your practice or laboratory.

- If your primary focus is high-volume lab production: Invest in furnaces with larger chambers and advanced programming options to handle a diverse range of materials and maximize throughput.

- If your primary focus is chairside, same-day dentistry: Prioritize compact, fast-sintering furnaces specifically designed to integrate with your in-office CAD/CAM milling unit.

- If your primary focus is creating high-end, aesthetic restorations: Select a furnace renowned for its precise temperature control and specialized glazing cycles to achieve optimal translucency and characterization.

Ultimately, investing in modern furnace technology is a direct investment in the predictability, quality, and longevity of your dental restorations.

Summary Table:

| Key Improvement | Description |

|---|---|

| Precision and Consistency | Programmable heat cycles ensure uniform sintering for predictable outcomes. |

| Strength and Durability | Eliminates pores, increasing density and resistance to fracture. |

| Aesthetics and Biocompatibility | Enables natural-looking, metal-free restorations with controlled glazing. |

| Material Versatility | Supports advanced ceramics like zirconia and lithium disilicate. |

Elevate your dental lab's capabilities with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces tailored for precise sintering. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization to meet your unique experimental needs. Achieve superior crown manufacturing with enhanced strength, aesthetics, and consistency—contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab